Aluminum chromium zirconium nitride composite ceramic material and preparation method thereof

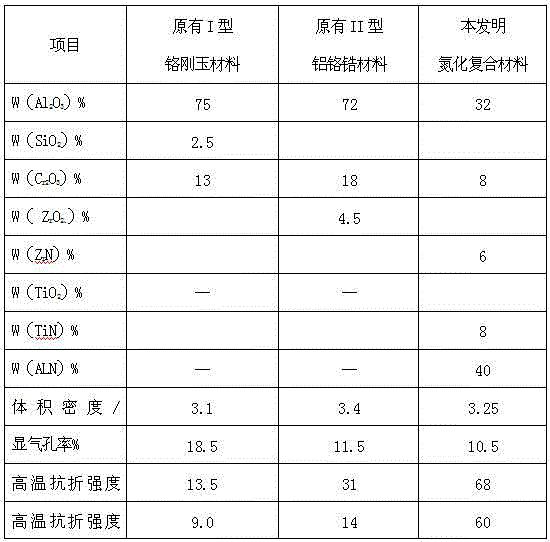

A technology of aluminum chromium zirconium nitride and composite ceramics, which is applied in the field of aluminum chromium zirconium nitride composite ceramic materials and its production, can solve the problems of affecting enterprise benefits, high porosity, poor oxidation resistance, etc., and achieve improved thermal shock resistance Performance, solution to waste residue pollution, small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

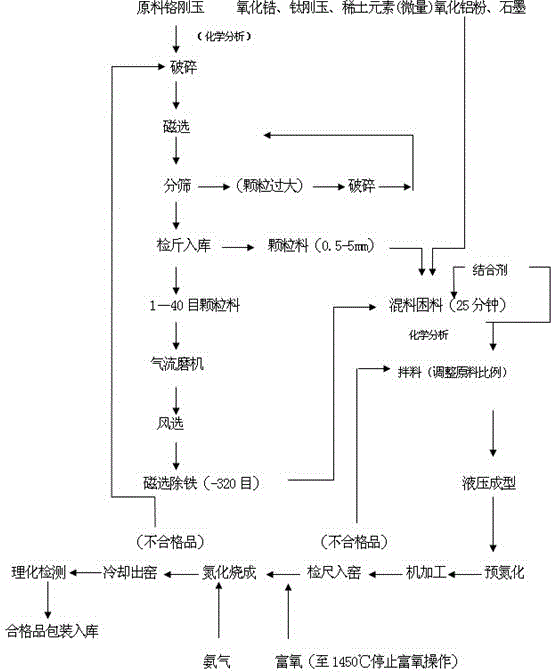

Method used

Image

Examples

Embodiment 1

[0030] Firstly, chemically analyze the raw material chromium corundum, then crush it with a jaw crusher, and then crush it with a cone crusher until the largest particle size does not exceed 5 mm, then go through magnetic separation with a strong magnetic separator for iron removal, and then sieve. The larger particles are sent to the roller crusher for further crushing. Send the material with a particle size of 0.5-5 mm into the mixer and mix with chromium oxide, titanium corundum (TiO 2 .AL 2 o 3 ), rare earth elements, alumina powder, graphite, and binder; grind particles smaller than 0.5mm to -320 mesh, and combine them with zirconia, titanium corundum, rare earth elements, graphite, and binder after magnetic separation to remove iron After 25 minutes of mixing, chemical analysis was carried out; 40 kg of zirconia, 50 kg of titanium corundum, 10 kg of rare earth elements, 200 kg of alumina powder, 150 kg of graphite, and 40 kg of binder (the binder is 85% phosphoric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com