Carbon nanotube composite thin film field emission cathode preparation method

A carbon nanotube composite, field emission cathode technology, applied in cold cathode manufacturing, discharge tube/lamp manufacturing, nanotechnology and other directions, can solve the problems of limiting field emission performance, limiting emission current, small contact area, etc. The effect of improving field emission performance, reducing ohmic contact resistance and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

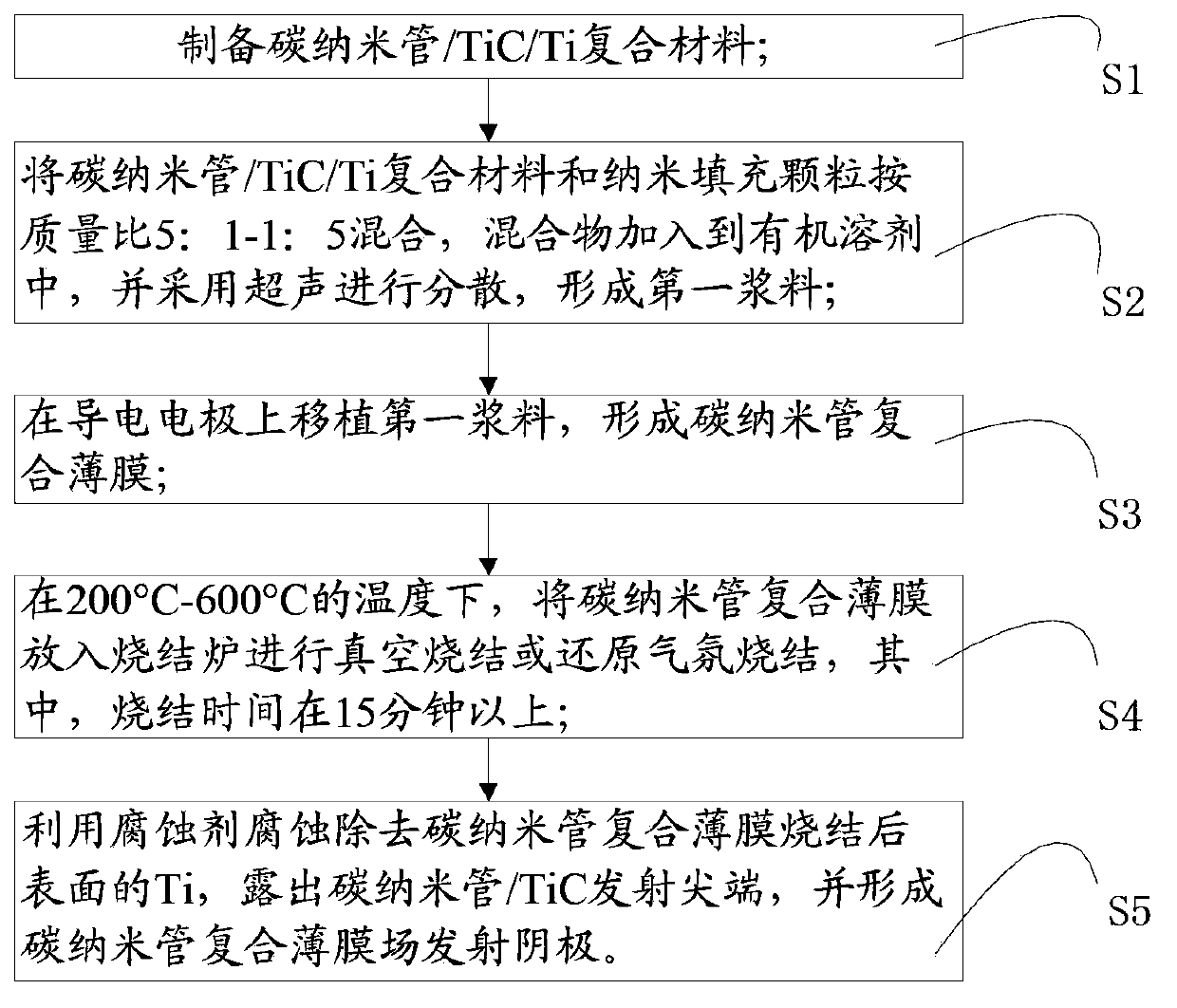

[0023] Please refer to figure 1 , the invention provides a method for preparing a carbon nanotube composite film field emission cathode, the method comprising:

[0024] S1, preparing carbon nanotube / TiC / Ti composite material;

[0025] In said S1, the specific method for preparing carbon nanotubes / TiC / Ti composite materials is as follows: carbon nanotubes, TiCl 3 and TiH 2 Put the uniform mixed powder into the sealed cavity, vacuumize the sealed cavity and heat it for 10 minutes to 2 hours. After the mixed powder volatilizes and undergoes a chemical reaction for 1 hour, reduce the temperature of the sealed cavity to room temperature to obtain the reaction product. The solvent cleans the reaction product to obtain the carbon nanotube / TiC / Ti composite material. Among them, the vacuum degree is 10 -2 Below Pa, the heating temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com