Plant polysaccharide medicinal enteric hard-shell capsule and preparation method thereof

A plant polysaccharide and capsule technology, which can be used in capsule delivery, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of unqualified quality, difficult control of capsule preparation process, and moisture absorption and deterioration of drugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

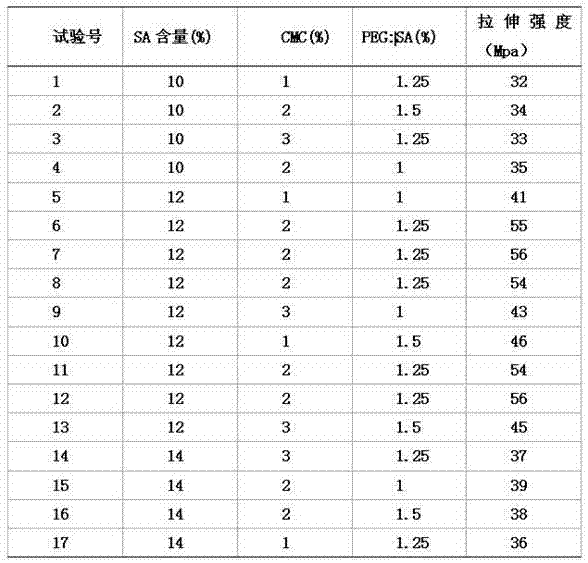

Embodiment 1

[0077] Embodiment 1, a plant polysaccharide medicinal enteric-coated hard-shell capsule, the main weight ratio of the capsule consists of:

[0078] Sodium alginate 10;

[0079] CMC 1;

[0080] Polyethylene glycol PEG-400, its content is 1% of sodium alginate.

Embodiment 2

[0081] Embodiment 2, a plant polysaccharide medicinal enteric-coated hard-shell capsule, the main weight ratio of the capsule is composed of:

[0082] Sodium alginate 14;

[0083] CMC 3;

[0084] Polyethylene glycol PEG-400, its content is 1.5% of sodium alginate.

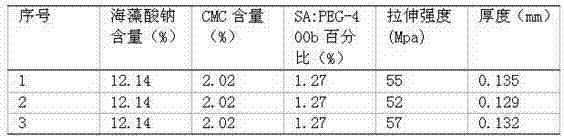

Embodiment 3

[0085] Embodiment 3, a plant polysaccharide medicinal enteric-coated hard-shell capsule, the main weight ratio of the capsule is composed of:

[0086] Sodium alginate 12;

[0087] CMC 2;

[0088] Polyethylene glycol PEG-400, its content is 1.27% of sodium alginate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com