Novel flame retardant and anti-static biodegradable material and preparation method thereof

A biodegradable material, flame retardant and antistatic technology, which is applied in the field of flame retardant and antistatic biodegradable materials and its preparation, can solve the problems of adding a single antistatic agent, achieve excellent mechanical properties and processing properties, and have long-lasting antistatic properties. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

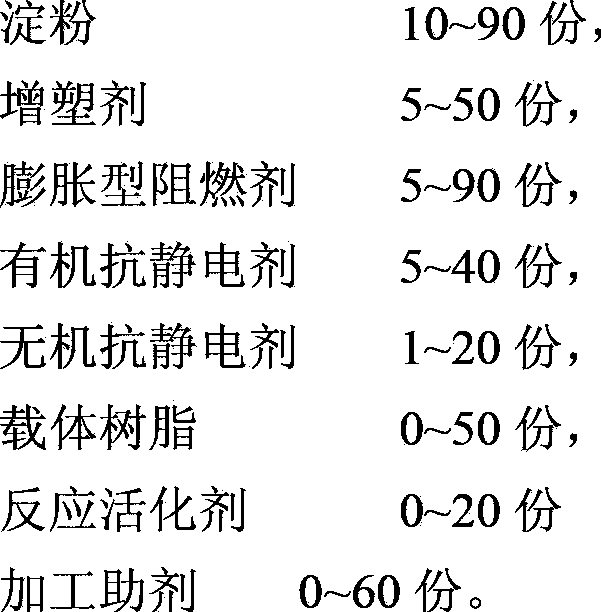

Method used

Image

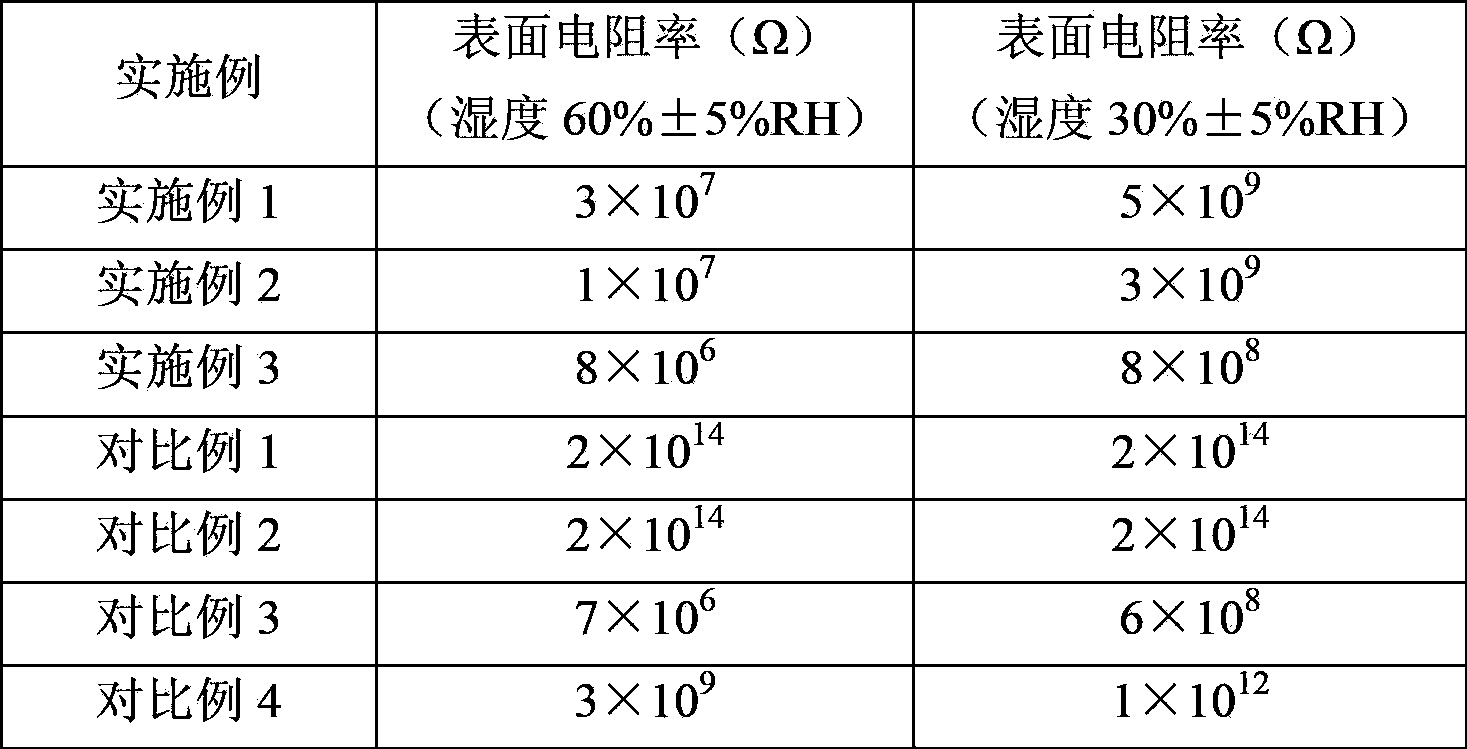

Examples

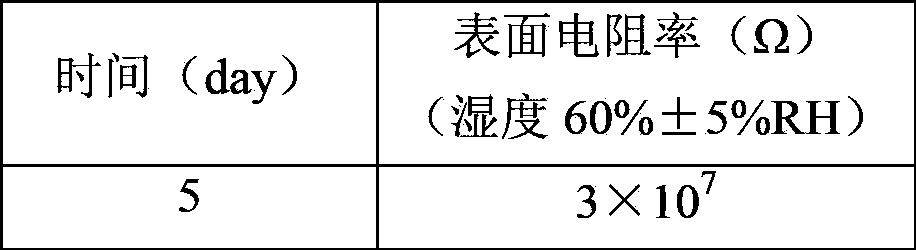

Embodiment 1

[0063] (1) Preparation of flame retardant and antistatic starch master batch: 35 parts of corn starch, 15 parts of plasticizer glycerin, 25 parts of intumescent flame retardant (corn starch: ammonium polyphosphate: melamine=1:3:1), 8 parts of organic antistatic agent glycerin oleate, 2 parts of inorganic antistatic agent aluminum oxide, 7 parts of carrier resin polybutylene adipate-terephthalate, 4 parts of activator 1,6-cyclohexanediisocyanate and 4 parts of heat stabilizer Irgafos168 were sequentially added to the high mixer and mixed for 5 minutes, then added to a twin-screw extruder at 120°C for extrusion and granulation to obtain a flame-retardant and anti-static starch masterbatch. The length-to-diameter ratio L / D of the screw is 15, and the time for melt blending is 5 minutes;

[0064] (2) Take 30 parts of the flame retardant and antistatic starch masterbatch in step (1) and 70 parts of the biodegradable resin polybutylene adipate-terephthalate and add them to the high ...

Embodiment 2

[0066] (1) Preparation of flame retardant and antistatic starch masterbatch: 35 parts of wheat starch, 15 parts of plasticizer sorbitol, 28 parts of intumescent flame retardant (wheat starch: magnesium ammonium phosphate: melamine=1:3:1 ), 8 parts of organic antistatic agent polyglycerol laurate, 2 parts of inorganic antistatic agent zinc oxide, 7 parts of carrier resin polybutylene adipate-terephthalate and 5 parts of activator Stabaxol-P200 were sequentially added to Mix in a high mixer for 10 minutes, then add it to a twin-screw extruder at 100°C to extrude and granulate to obtain a flame-retardant and antistatic starch masterbatch, which is ready for use, wherein the screw speed is 100rpm, and the screw length-to-diameter ratio L / D is 20 , the time of melt blending is 10min, and finally passes through the granulator;

[0067] (2) Take 40 parts of the flame retardant and antistatic starch masterbatch in step (1), 60 parts of biodegradable resin polybutylene adipate-terephth...

Embodiment 3

[0069] (1) Preparation of flame retardant and antistatic starch masterbatch: mix 35 parts of potato starch, 15 parts of plasticizer urea, and 30 parts of intumescent flame retardant (potato starch: zinc borate: dicyandiamide = 1:3:1) , 12 parts of organic antistatic agent polyethylene glycol stearate, 1 part of inorganic antistatic agent carbon black, and 7 parts of carrier resin polybutylene adipate-terephthalate were sequentially added to the high mixer and mixed for 8 minutes , and then added to a twin-screw extruder at 130°C to extrude and granulate to obtain a flame-retardant and antistatic starch masterbatch, which is ready for use, wherein the screw speed is 150rpm, the screw length-to-diameter ratio L / D is 25, and the time for melt blending 8 minutes;

[0070] (2) Take 45 parts of flame retardant and antistatic starch masterbatch in step (1), 2 parts of reaction activator maleic anhydride and 53 parts of polybutylene adipate-terephthalate and add them to the high mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com