Gamma-polyglutamic acid production gene engineering bacterial and method for producing high-yield gamma-polyglutamic acid through gamma-polyglutamic acid production gene engineering bacterial

A technology of genetically engineered bacteria and genetically engineered strains, applied in the field of bioengineering, can solve the problems of low PGA concentration, reduced dissolved oxygen concentration of fermentation broth, low yield of γ-polyglutamic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

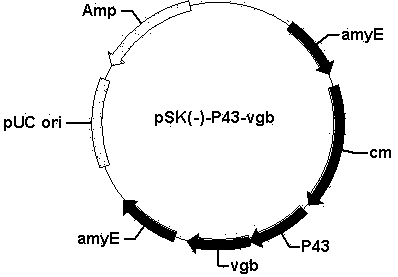

[0019] Embodiment one : Construction of pSK(-)-P43-vgb recombinant vector expressing hemoglobin gene

[0020] Using conventional molecular biology techniques, the nucleotide sequences 1-500 and 1381-1984 of the 5' end of the Bacillus subtilis amylase gene were cloned into the pBluescriptsk (-) plasmid respectively. Xho I, Hind III and XbaⅠ, SacⅡ between the sites; the primers used were:

[0021] AmyE1 5'ATTGCTCGAGATGTTTGCAAAACGATTCAAA3'

[0022] AmyE2 5' GGATAAGCTTTGTGTGTTTCCATGTGTCCAGT3'

[0023] AmyE3 5' ATTGTCTAGAGCTGTGCTTTATCCTGATGATA3'

[0024] AmyE4 5' ATTACCGCGGTCAATGGGGAAGAGAACCGCT3'

[0025] Using the Bacillus subtilis genome as a template, the

[0026] P1 5' ATTAGAATTCTGTCGACGTGCATGCAGGC3'

[0027] P2 5' TAGGATCCTATAATGGTACCGCTATCACT3'

[0028] Use primers to amplify the P43 promoter gene by PCR; insert it into the pBluescriptsk (-) plasmid EcoRI with BamHI between sites;

[0029] With pUC19-vgb as template, with

[0030] VGB1 5'ATTGGATCCGGAAGACCCTCA...

Embodiment 2

[0037] Embodiment two : High-yield γ-polyglutamic acid engineering bacteria Bacillus subtilis ( Bacillus subtilis ) The construction of the FRD518

[0038] The vector pSK(-)-P43-vgb constructed in Example 1 was used with restriction endonuclease XhoI or SacⅡ Linearized; dephosphorylated with alkaline phosphatase and recovered for electrotransformation. The specific method is as follows:

[0039] (1) Vaccination B. subtilis In 3ml LB medium, cultivate overnight. (2) Take 2.6ml of overnight culture and inoculate into 40ml (LB+0.5M sorbitol), culture at 37℃, 200rpm until OD600=0.85~0.95. (3) Place the bacterial solution in an ice-water bath for 10 min, then centrifuge at 5000 g for 5 min at 4°C to collect the bacterial cells. (4) Use 50ml of pre-cooled electroporation medium (0.5M sorbitol, 0.5M mannitol, 10% glucose), re-suspend the bacteria, centrifuge at 5000g, 5min, 4°C to remove the supernatant, and rinse 4 times in this way. (5) Suspend the washed cells in 1ml ...

Embodiment 3

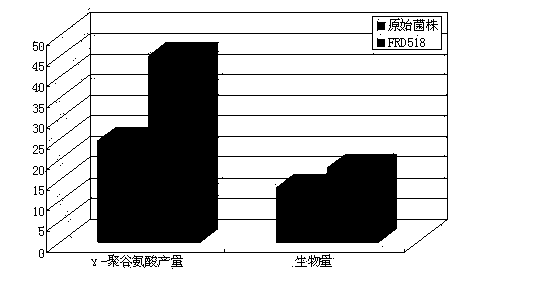

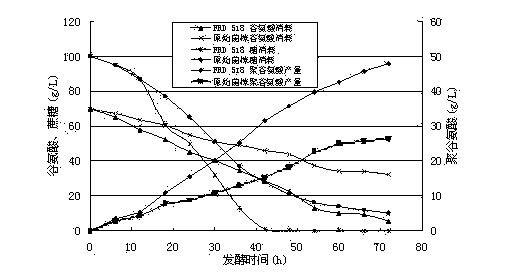

[0040] Embodiment Three : Screening and verification of high-yield γ-polyglutamic acid by genetically engineered strain FRD518

[0041] Pick 36 fast-growing positive clone strains, and select the strain with the highest viscosity of the fermentation liquid after shake-flask fermentation screening, named as Bacillus subtilis FRD518. The original strain and Bacillus subtilis FRD518 were respectively inoculated into 250ml Erlenmeyer flasks containing 50ml seed medium, cultured overnight at 37°C, and the shaker speed was 210rpm. The cultured seeds were inoculated into 250ml Erlenmeyer flask containing 50ml fermentation medium with 2% inoculum amount, cultured at 37°C for 48~72h, and the shaker speed was 210rpm. After the fermentation, take 1ml of fermentation broth, dilute it 10 times, centrifuge at 12000r / min, 4°C for 10min, take the supernatant, filter it through a microporous membrane, and perform chromatographic analysis. The chromatographic analysis conditions are: c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com