Method for preparing antioxidant collagen peptide

A technology of oxidizing glue and collagen, which is applied in the field of food biology, can solve the problems of low activity of antioxidant peptides, lack of separation and purification, and deep color, so as to achieve high antioxidant activity, improve sensory quality, and deep color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 50 g of collagen into a Erlenmeyer flask, add 1000 mL of artificial gastric juice, seal it, and simulate gastric digestion in a constant temperature shaking water bath at 37°C and 150 rpm for 3 h, then adjust the pH to 6.8 with 1.0 mol / L NaOH, Add 10 g of trypsin to continue simulating small intestine digestion for 5 h. After the digestion, the reaction was terminated in a boiling water bath for 12 min, and the supernatant was collected by centrifugation at 10,000 g for 15 min.

[0025] Using the Millipore Pellicon ultrafiltration system, pump the above digested solution to the surface of a regenerated cellulose ultrafiltration membrane with a molecular weight cut-off of 1 kDa, collect the filtrate until its absorbance at 220 nm is close to 0, and then concentrate it to 100 mL by rotary evaporation About, vacuum freeze-dried, about 55 g.

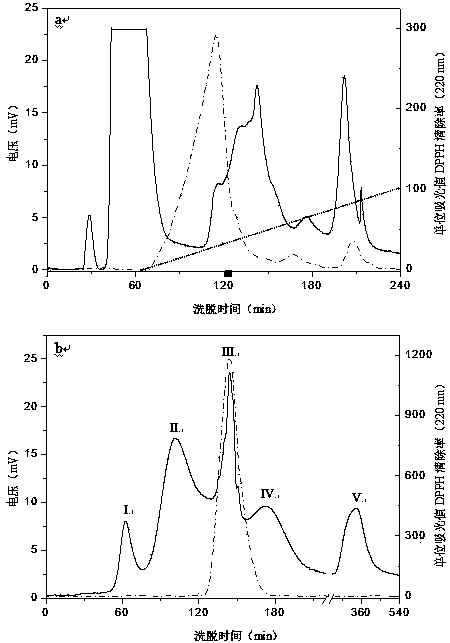

[0026] Dissolve the fraction obtained from the above membrane separation in 0.05 mol / L HAc-NaAc buffer (pH = 4.5) to 50 mg / mL...

Embodiment 2

[0028] Weigh 50 g of gelatin into a digestion bottle, add 500 mL of artificial gastric juice, seal it, simulate gastric digestion in a constant temperature shaking water bath at 37°C and 180 rpm for 2 h, then adjust the pH to 6.8 with 1.0 mol / L NaOH, add 5 g of trypsin continued to simulate digestion in the small intestine for 4 h. After the digestion, the reaction was terminated in a boiling water bath for 10 min, and the supernatant was collected by centrifugation at 10,000 g for 10 min.

[0029] Using the Millipore Pellicon ultrafiltration system, pump the above digested solution to the surface of a regenerated cellulose ultrafiltration membrane with a molecular weight cut-off of 1 kDa, collect the filtrate until its absorbance at 220 nm is close to 0, and then concentrate it to 100 mL by rotary evaporation About, vacuum freeze-dried, about 52 g.

[0030] Dissolve the fraction obtained from the above membrane separation in 0.05 mol / L HAc-NaAc buffer (pH = 4.5) to 100 mg / mL...

Embodiment 3

[0032] Weigh 50 g of gelatin into a Erlenmeyer flask, add 1250 mL of artificial gastric juice, seal it, simulate gastric digestion in a constant temperature shaking water bath at 37°C and 120 rpm for 4 h, then adjust the pH to 6.8 with 1.0 mol / L NaOH, add 12.5 g of trypsin continued to simulate digestion in the small intestine for 6 h. After digestion, the reaction was terminated by boiling water bath for 15 min, and the supernatant was collected by centrifugation at 10,000 g for 20 min.

[0033]Using the Millipore Pellicon ultrafiltration system, pump the above digested solution to the surface of a regenerated cellulose ultrafiltration membrane with a molecular weight cut-off of 1 kDa, collect the filtrate until its absorbance at 220 nm is close to 0, and then concentrate it to 100 mL by rotary evaporation About, vacuum freeze-dried, about 56 g.

[0034] Dissolve the fraction obtained from the above membrane separation in 0.05 mol / L HAc-NaAc buffer (pH = 4.5) to 200 mg / mL, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com