Etching processing method and device for high-quality alumina ceramics

A technology of alumina ceramics and processing methods, which is applied in metal processing equipment, manufacturing tools, welding/welding/cutting articles, etc., can solve the problem of obvious recondensation layer, which affects the micromachining quality and dimensional accuracy of laser-etched alumina ceramic materials , melting and other problems to achieve the effect of increasing the etching depth and avoiding blackening and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

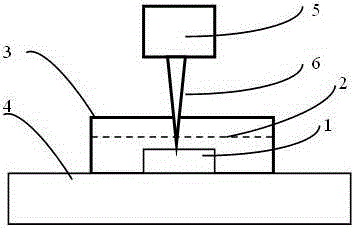

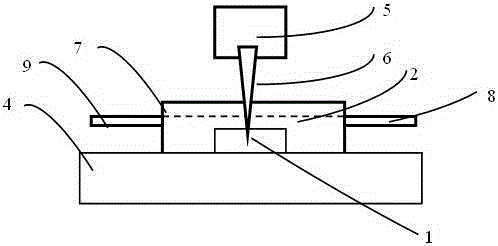

Image

Examples

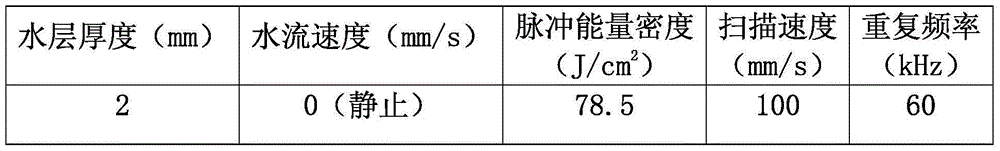

example 1

[0022] The present invention adopts the Awave-355-10W-25K model all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, the output wavelength is 355nm, the pulse energy is from 0 to 500μJ, and the frequency is 10 to 100kHz, and the aluminum oxide ceramics are processed under water. Laser etching processing. The processing parameters of UV laser etching are shown in Table 1. The etching quality of alumina ceramics obtained by the invention achieves the effects of no blackened metamorphic layer and obvious reduction of the roughness of the etching bottom surface.

[0023] Table I

[0024]

example 2

[0026] The present invention adopts the Awave-355-10W-25K model all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, the output wavelength is 355nm, the pulse energy is from 0 to 500μJ, and the frequency is 10 to 100kHz, and the aluminum oxide ceramics are processed under water. Etching processing. The UV laser etching processing parameters used are shown in Table 2. The etching quality of alumina ceramics obtained by the invention achieves the effects of no blackened metamorphic layer and obvious reduction of the roughness of the etching bottom surface.

[0027] Table II

[0028]

example 3

[0030] The present invention adopts the Awave-355-10W-25K model all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, the output wavelength is 355nm, the pulse energy is from 0 to 500μJ, and the frequency is 10 to 100kHz, and the aluminum oxide ceramics are processed under water. Etching processing. The processing parameters of UV laser etching are shown in Table 3. The etching quality of alumina ceramics obtained by the invention achieves the effects of no blackened metamorphic layer and obvious reduction of the roughness of the etching bottom surface.

[0031] Table three

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com