Method for preparing 2.5 D micro-nano structure through gray exposure

A micro-nano structure, grayscale technology, applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices and other directions, can solve the problems of inconvenient and flexible control of the high level of micro-nano structures, and achieve shortened exposure time, high graphics accuracy, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

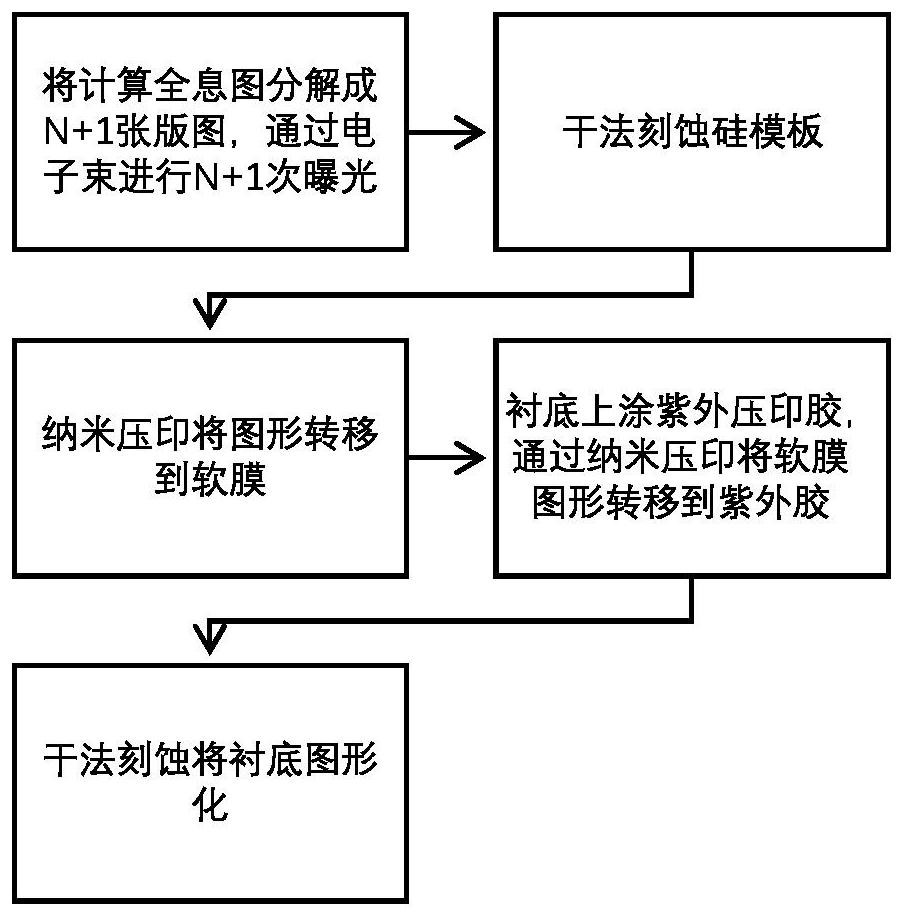

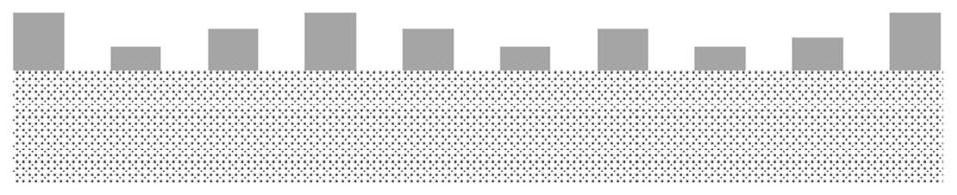

[0035] Such as figure 1 As shown, this embodiment provides a method for preparing a spatial light filter with a 2.5D micro-nano structure by electron beam grayscale exposure, including the following steps:

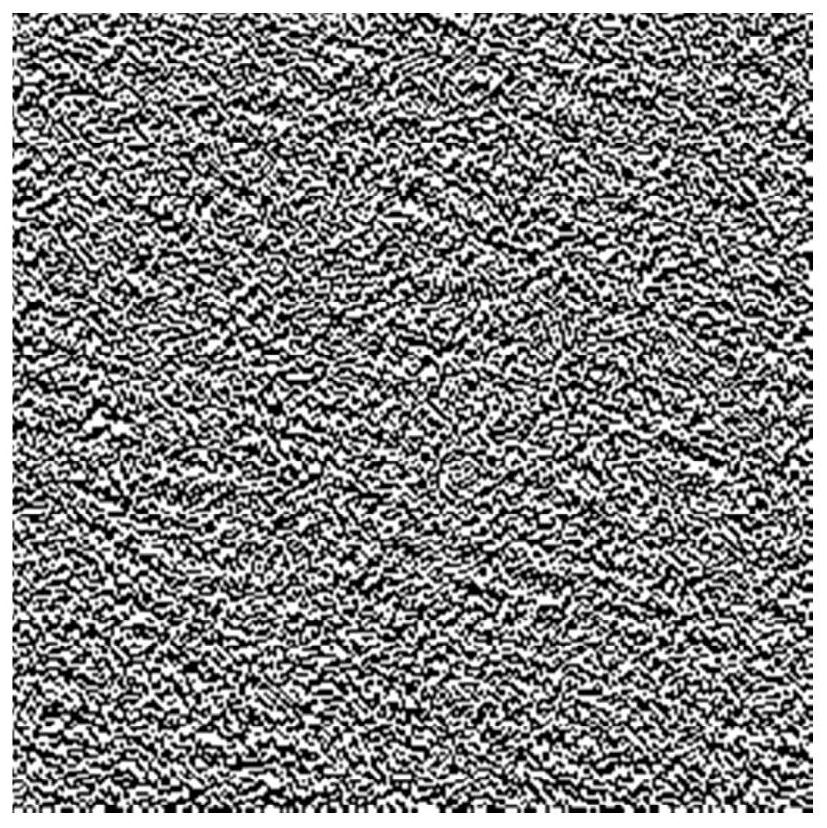

[0036] Step 1: Perform Fourier transform on the spectral surface of the object light wave, calculate the amplitude and phase through the Gauss-Seidel iterative method, assign the amplitude to 0, retain the phase, iterate 100 times, and optimize to obtain a pure phase hologram . Divide the phase of each pixel of the hologram into 2 to the 5th power, that is, 32 levels, divide by 2 in turn to get the remainder, and establish 5 layouts, one of which is shown in Figure 2(a), and then calculate the Union to create an additional compensation layout. 6 e-beam exposures after spin-coating e-beam photoresist on silicon wafers;

[0037] Among them, the exposure beam current of the compensation pattern is 20hA, and the dose is 164μC / cm 2 , the beam currents of the electron beam e...

Embodiment 2

[0054] This embodiment provides a method for preparing a spatial light filter with a 2.5D micro-nano structure by gray-scale exposure of ultraviolet overcoating, including the following steps:

[0055] Step 1: Perform Fourier transform on the spectrum surface of the object light wave, discard the amplitude through the Gauss-Seidel iteration method, iterate 100 times, and optimize to obtain a pure phase hologram. Divide the phase of each pixel of the hologram into 2 to the 5th power, that is, 32 levels, divide by 2 in turn to get the remainder, and establish 5 layouts, and then find the union of these 5 layouts to create an additional compensation layout. After spin-coating AZ5214 UV photoresist on the silicon wafer, perform 6 UV mask overlay alignment exposures;

[0056] Among them, the exposure dose of the compensation pattern is 32mJ / cm 2 , the UV exposure doses of the remaining 5 layouts were 2mJ / cm 2 , 4mJ / cm 2 , 8mJ / cm 2 、16mJ / cm 2 and 32mJ / cm 2 ;

[0057] After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com