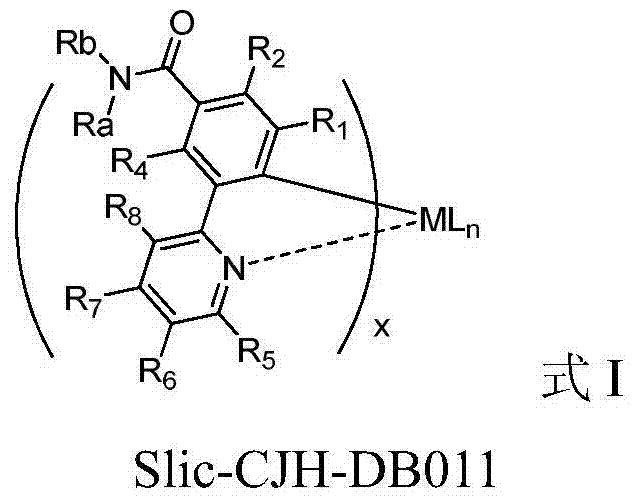

Organic electroluminescent material and application thereof

A reaction and compound technology, applied in the field of organic electroluminescence display, can solve the problems of difficult to improve luminous efficiency and small luminous contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

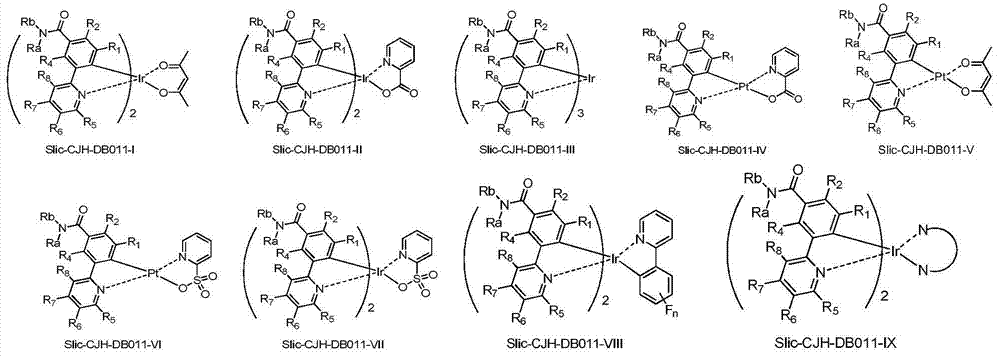

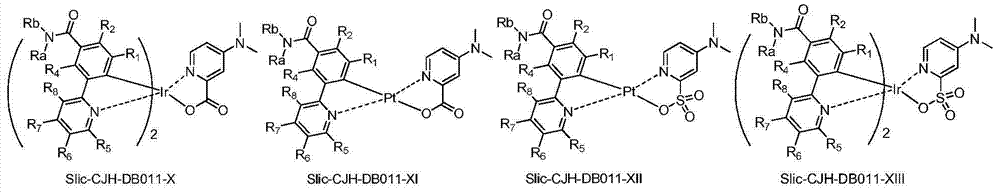

Method used

Image

Examples

Embodiment 1

[0076] Example 1 Preparation of compound Slic-CJH-DB011-I01

[0077]

[0078] Step 1: Preparation of compound Slic-CJH-1

[0079]

[0080] 15.8g of 2-bromopyridine was dissolved in 250ml of toluene, 120ml of water was added, and under the protection of nitrogen, 16g of 3-methyl-4-fluorophenylboronic acid, 42.5g of sodium carbonate and 578mg of Pd(PPh 3 ) 4 After stirring, heating and refluxing for 8 hours, it was cooled to room temperature, the organic phase was separated, the aqueous phase was extracted with ethyl acetate, the organic phase was dried with anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain 17g of colorless liquid at room temperature Place to cure.

[0081] Step 2: Preparation of compound Slic-CJH-2

[0082]

[0083] Mix 10g of Slic-CJH-1 with 250ml of water, add 3.2g of sodium hydroxide, heat to reflux, add potassium permanganate in batches, continue to reflux for 4 hours, cool to room temperature, filter, filter cake, wash with wate...

Embodiment 2

[0100] Example 2 Preparation of compound Slic-CJH-DB011-II02

[0101]

[0102] Step 1: Preparation of compound Slic-CJH-1

[0103]

[0104] Referring to the first step of Example 1, the 3-methyl-4-fluorophenylboronic acid in the first step of Example 1 was replaced with 2,4-difluoro-3-methylphenylboronic acid to obtain a white solid.

[0105] Step 2: Preparation of compound Slic-CJH-2

[0106]

[0107] Referring to the second step of Example 1, the 2-(4-fluoro-3-methylphenyl)pyridine in the second step of Example 1 was replaced with 2-(2,4-difluoro-3-methylphenyl) Pyridine, a white solid is obtained.

[0108] The third step: Preparation of compound Slic-CJH-4

[0109]

[0110] Dissolve 5g of raw material Slic-CJH-2 in 50ml of dry DMF, add 4.3g of diphenylamine and 5.5g of triethylamine, then add 0.5g of 1-hydroxybenzotriazole and 4.9g of 1-ethylamine -(3-Dimethylaminopropyl)carbodiimide hydrochloride, under the protection of nitrogen, heat up to 80℃ and stir for 12 hours, cool to room ...

Embodiment 3

[0121] Example 3 Preparation of compound Slic-CJH-DB011-III08

[0122]

[0123] Referring to the first step to the fourth step of Example 2, the diiridium bridged compound Slic-CJH-5 was prepared as a yellow solid. Referring to the sixth step of Example 1, the acetylacetone complex Slic-CJH-DB011-I08 was prepared as a yellow solid.

[0124]

[0125] 435mg of compound Slic-CJH-DB011-I08 and 290mg of N,N-diethyl-2,6-difluoro-3-(pyridin-2-yl)benzamide and 20ml of glycerol were heated to 180°C, The reaction was stirred for 8 hours, cooled to room temperature, the reaction solution was poured into 200ml of 1N dilute hydrochloric acid, filtered with suction, the filter cake was washed with water, and the obtained solid was separated and purified with a silica gel column to obtain 340mg of Slic-CJH-DB011-III08, yellow solid.

[0126] Experimental data:

[0127] (1) Glass transition temperature (DSC): 305.66℃;

[0128] (2) UV maximum absorption wavelength (DCM): 325nm, 355nm;

[0129] (3) Ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com