N,O-carboxymethyl chitosan-polyaldehyde hyaluronic acid gel and use thereof

A technology of carboxymethylated chitosan and carboxymethyl chitosan, applied in the field of N,O-carboxymethylated chitosan-polyaldehyde-based hyaluronic acid gel, can solve the influence of film adhesion , It is impossible to completely cover the wound surface, and the residence time is short, so as to achieve the effect of good structural integrity, good cell compatibility, and anti-adhesion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

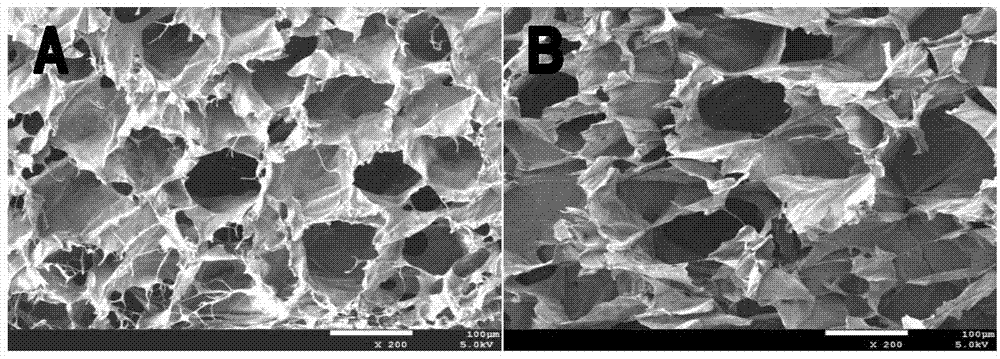

Examples

preparation example Construction

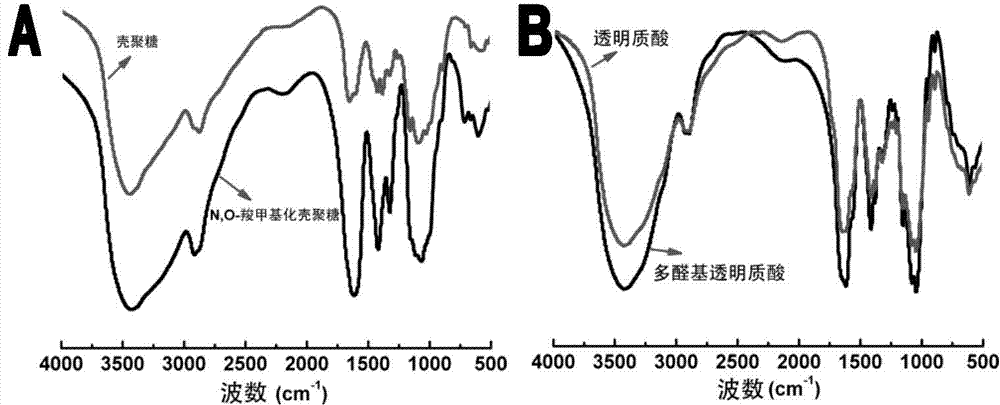

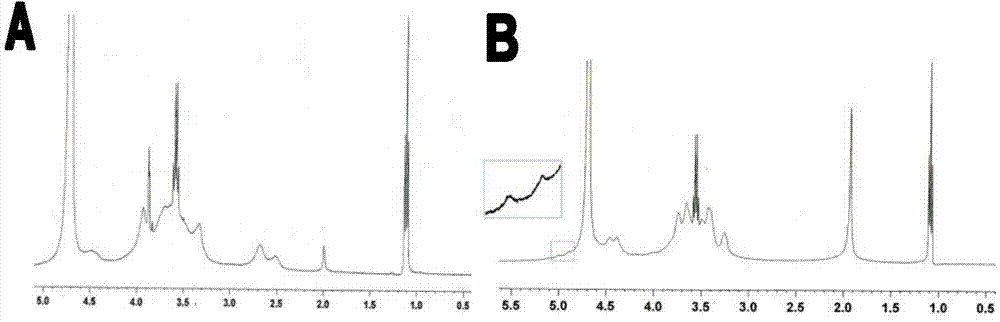

[0059] The preparation method of N,O-carboxymethylated chitosan-polyaldehyde hyaluronic acid gel, the specific operation steps are as follows:

[0060] a. React chloroacetic acid and chitosan with sodium hydroxide aqueous solution at room temperature for 1-4 hours, wherein the mass ratio of chitosan to chloroacetic acid is 0.1-10:1; then increase the reaction temperature to 50-80°C to continue the reaction Terminate the reaction after 1-4 hours; filter out the solid, wash the solid with 60-90% ethanol or methanol aqueous solution; dissolve the obtained solid in water, use a dialysis bag with a molecular weight cut-off of 8000-14000 to perform dialysis treatment in water for 3 days, and then freeze-dry , to obtain N, O-carboxymethyl chitosan. Wherein, the aqueous sodium hydroxide solution of chitosan is obtained by adding chitosan to 20-60% aqueous sodium hydroxide solution and placing it at -20°C-0°C for 1-24h; the chitosan The mass ratio to sodium hydroxide is 0.1-10:1.

[...

Embodiment 1

[0083] a. Preparation of N,O-carboxymethylated chitosan: Put 5g of chitosan (molecular weight 1 million, x≈2130) in a 250mL round bottom flask, add 25mL of 40% sodium hydroxide aqueous solution, and put the flask Store in a refrigerator at -20°C for overnight treatment. In addition, dissolve 20g of chloroacetic acid with a certain amount of water and place it in a constant pressure funnel. Slowly add the aqueous solution of chloroacetic acid dropwise under stirring. After the dropwise addition, react under stirring conditions at room temperature 2h, and then increase the reaction temperature to 60°C to continue the reaction for 2h and terminate the reaction. The mixed system in the flask was suction-filtered, and the obtained filter residue was repeatedly washed 3 times with 80% ethanol aqueous solution. After washing, dissolve the obtained primary product with water, perform dialysis treatment in water for 3 days with a dialysis bag with a molecular weight cut-off of 8000-140...

Embodiment 2

[0087] a. Preparation of N,O-carboxymethylated chitosan: Put 5g of chitosan (molecular weight 1 million, x≈2130) in a 250mL round bottom flask, add 10mL of 20% sodium hydroxide aqueous solution, and put the flask Store in a -20°C refrigerator for overnight treatment. In addition, dissolve 5g of chloroacetic acid with a certain amount of water and place it in a constant pressure funnel. Slowly add the aqueous solution of chloroacetic acid dropwise under magnetic stirring conditions. After the dropwise addition, stir at room temperature. The reaction was carried out for 1 h, and then the reaction temperature was increased to 50 °C for 1 h, and then the reaction was terminated. The filter residue obtained from the suction filtration treatment of the mixed system in the flask was repeatedly washed 3 times with 60% ethanol aqueous solution. After washing, dissolve the obtained primary product with water, perform dialysis treatment in water for 3 days with a dialysis bag with a mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com