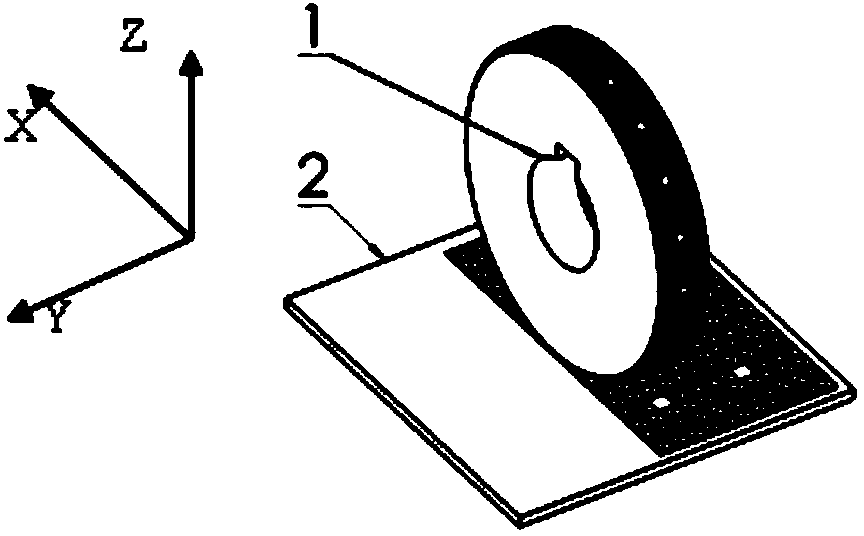

Method and rolling cutter for manufacturing LED multi-chip package substrate

A LED substrate and multi-chip packaging technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex tool routing, low processing efficiency, high cost, etc., and achieve simple process flow, less processing equipment, The effect of improving the utilization rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

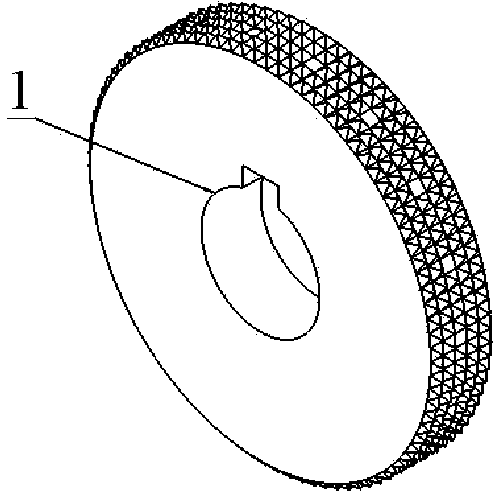

[0047] Taking the example of processing 1.5mm thick, taper hole side length 300×300um, taper hole depth 250um, taper hole spacing 350um, the substrate is copper plate, the process is as follows:

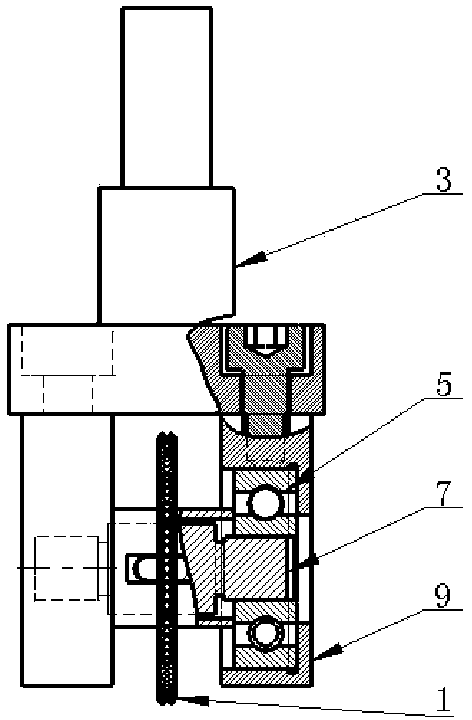

[0048](1) Design the rolling tool according to the structural size of the pre-prepared LED multi-chip integrated packaging substrate. The outer surface of the rolling tool has a five-row regular quadrangular pyramid structure, and this example adopts a regular quadrangular pyramid angle of 80°; this example uses a tool cone The tooth height is 400um, the outer diameter is 30mm, and the inner diameter is 10mm. The material is Cr12MoV. It is manufactured by precision grinding, and the surface roughness reaches Ra0.8. Remove a bevel tooth every 4 teeth on the middle row of the five-row bevel tooth structure of the pressing tool;

[0049] (2) Use the rolling fixture to fix the rolling tool on the main shaft of the ordinary vertical milling machine, and at the same time ensure that the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com