Zr based amorphous alloy and manufacturing method thereof

A technology of zirconium-based amorphous alloys and amorphous alloys, applied in the field of zirconium-based amorphous alloys and their preparation, can solve problems such as insufficient reaction between rare earth elements and harmful elements, increased material production costs, and reduced critical size of amorphous alloys , to achieve the effect of ensuring amorphous characteristics and mechanical properties, huge production practical value, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

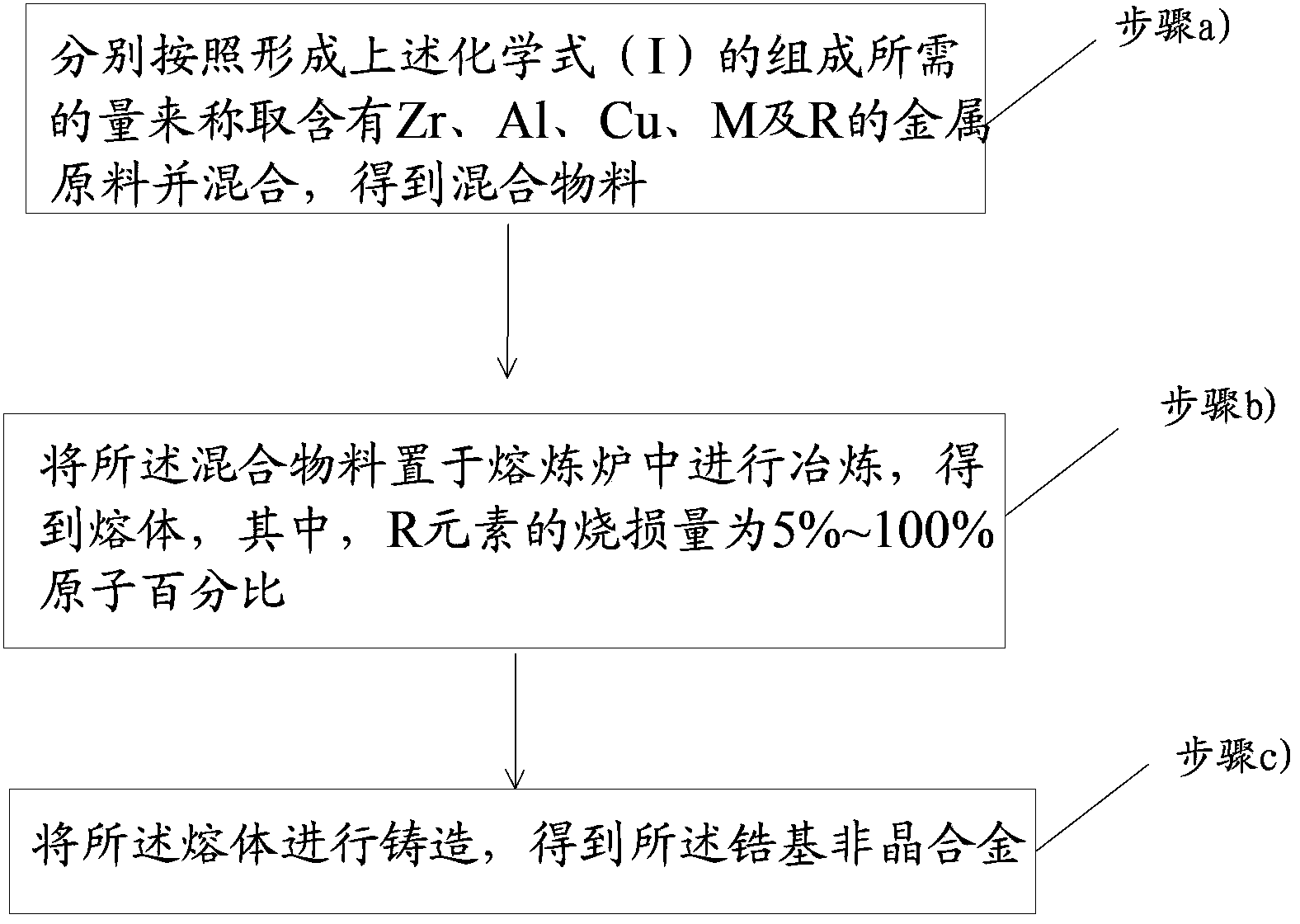

[0037] like figure 1 As shown, the preparation method of the zirconium-based amorphous alloy according to the embodiment of the present invention comprises the following steps:

[0038] a) Weighing and mixing metal raw materials containing Zr, Al, Cu, M and R according to the amount required to form the composition of the above chemical formula (I), to obtain a mixed material.

[0039] Considering that the M and R elements are generally highly active elements, and in order to facilitate smelting and mixing with the master alloy, it is preferable to add them in the form of master alloys. Further preferably, the R element is introduced in the form of an intermediate alloy of R element and aluminum.

[0040] Preferably, the e satisfies 0

[0041] Here, it should be noted that, considering the burning loss of the R element mentioned in the following step b), when weighing the R element, the amount of the R element that needs to be weighed is the corresponding to the above...

Embodiment 1

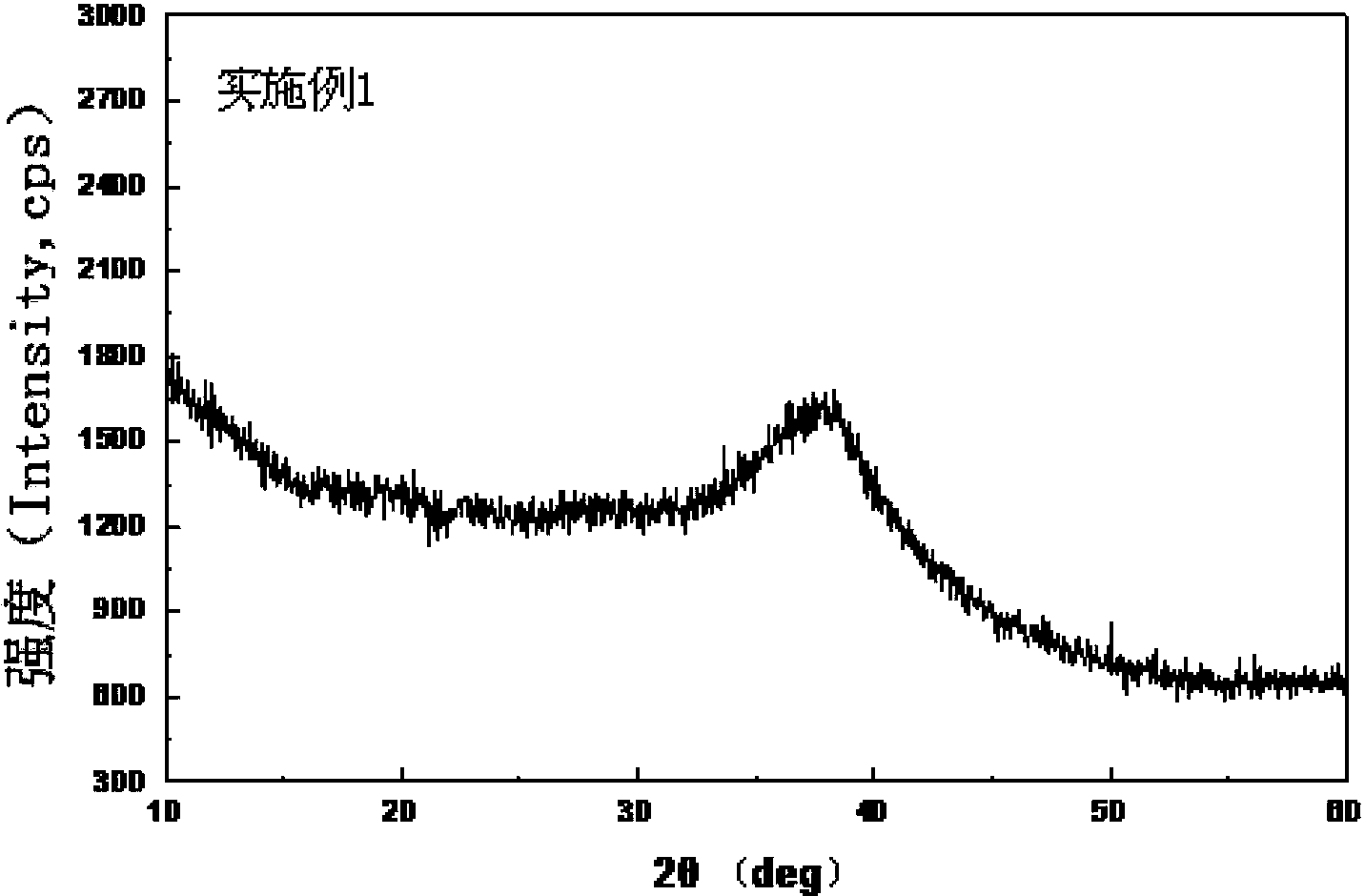

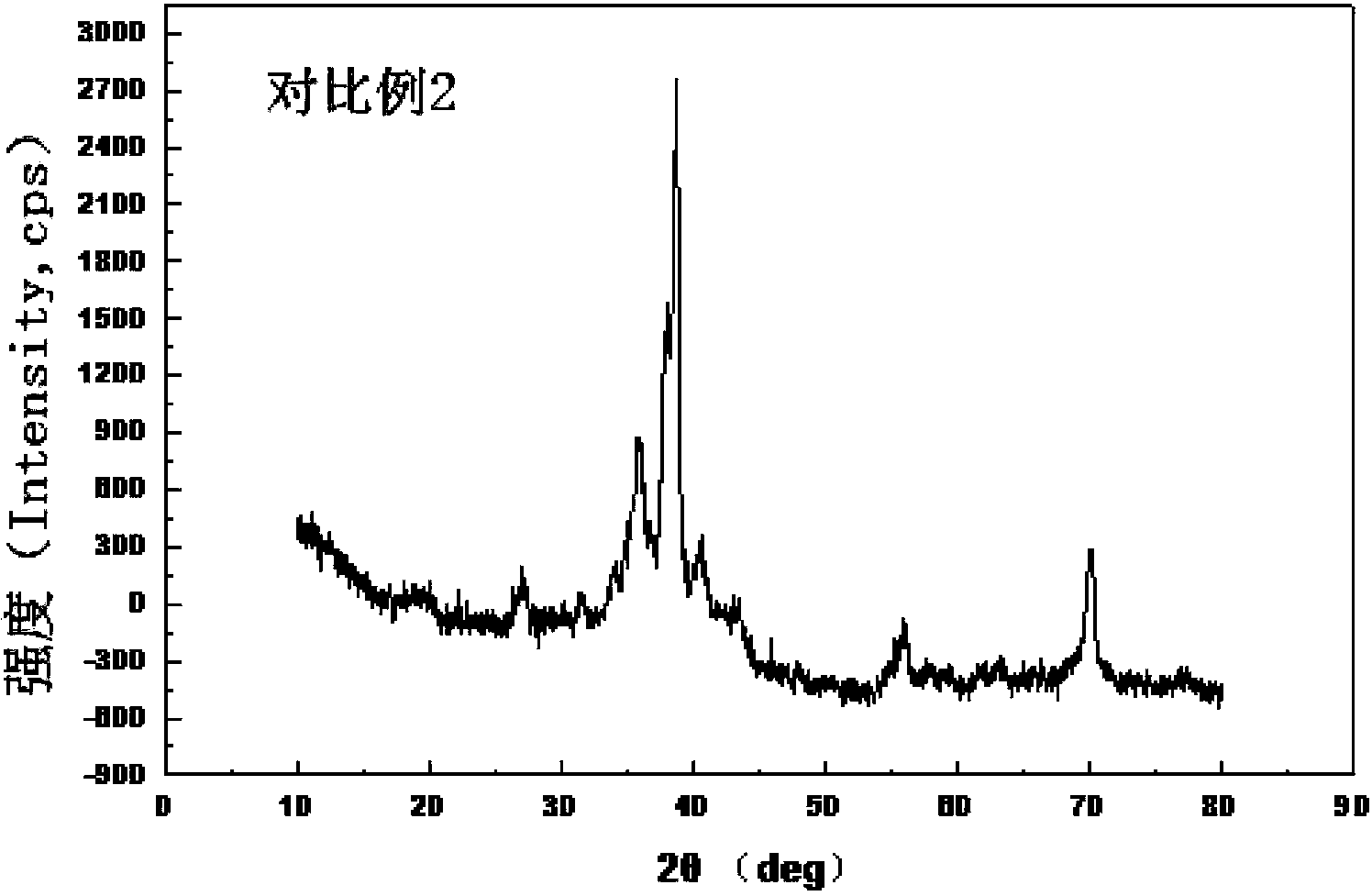

[0051]According to the final composition of Zr52Al10Cu30Ni8Y0.08 (among them, the burning loss of Y element is 15%), weigh zirconium metal, aluminum metal, copper metal, nickel metal, aluminum yttrium metal with material purity greater than 99%, mix them and put them into induction In the smelting furnace, the vacuum degree is 0.1Pa, induction melting is carried out, and the Y element is adjusted through real-time composition detection so that the burning loss of the Y element is 15% (1% composition deviation can be allowed), and the alloy is cast Amorphous rods of different sizes and amorphous plates with a wall thickness of 1.5mm.

[0052] The non-wafer rods of different sizes are processed into wafers of different specifications for critical dimension testing. The critical dimension is measured on the D / Max2500PC XRD diffractometer of Japan Rigaku Co., Ltd. The diffraction angle is 2theta between 20°~60 °, the scanning speed is 4° / min, the scanning voltage is 40Kv, and the ...

Embodiment 2

[0057] According to the final composition of Zr52Al10Cu30Ni8Er0.08 (the burning loss of Er element is 12%), weigh zirconium metal, aluminum metal, copper metal, nickel metal and erbium metal with a material purity greater than 99% and mix them, put them into the induction In the smelting furnace, the vacuum degree is 0.1Pa, induction melting is carried out, and the Er element is adjusted through real-time composition detection so that the burning loss of Er element is 12% (1% composition deviation can be allowed), and the alloy is cast Amorphous rods of different sizes and amorphous plates with a wall thickness of 1.5mm.

[0058] The non-wafer rods of different sizes are processed into wafers of different specifications for critical dimension testing. The critical dimension is measured on the D / Max2500PC XRD diffractometer of Japan Rigaku Co., Ltd. The diffraction angle is 2theta between 20°~60 °, the scanning speed is 4° / min, the scanning voltage is 40Kv, and the current is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical dimension | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com