Corrosion inhibitor for biodiesel production process by pyrolysis and application thereof

A technology of corrosion inhibitor and biodiesel, applied in the field of corrosion inhibitor, can solve the problems of less industrialization of grease thermal cracking units, equipment corrosion, complex product composition, etc., achieves good corrosion inhibition performance, solves high and low temperature corrosion, and has simple components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

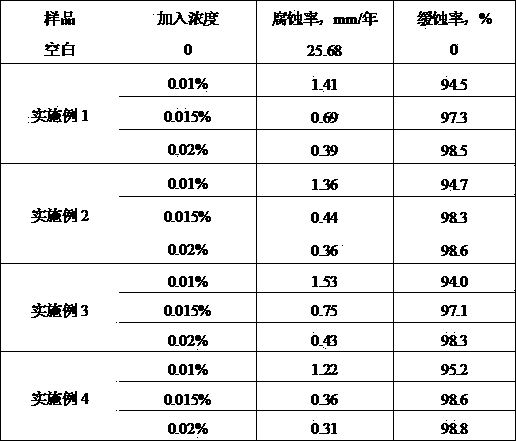

Examples

Embodiment 1

[0018] Example 1 Weigh 335 kg of 200# solvent oil and add it to a stirring tank to raise the temperature to 40°C, add 350 kg of naphthenic acid imidazoline amide, 60 kg of benzotriazole, 50 kg of 2-picoline, and 150 kg of monoethanolamine After stirring for 1 hour, add 55 kg of hexadecyl dimethyl benzyl ammonium bromide, stir for 2 hours, let it stand for 10 minutes, and take a sample as a clear yellow liquid to obtain 1000 kg of the required corrosion inhibitor. The obtained product is clear Yellow transparent oily viscous liquid. If the sample is turbid, it needs to keep warm and continue to stir until the sample is taken to obtain a clear yellow transparent liquid to prepare the corrosion inhibitor.

Embodiment 2

[0019] Example 2 Weigh 330 kg of 200# solvent oil and add it to a stirring tank to raise the temperature to 40°C, add 350 kg of naphthenic acid imidazoline amide, 50 kg of benzotriazole, 50 kg of 2-picoline, and 170 kg of diethanolamine After stirring for 1 hour, add 50 kg of octadecyl dimethyl benzyl ammonium bromide, stir for 2 hours, let it stand for 10 minutes, take a sample as a clear yellow liquid to obtain 1000 kg of the required corrosion inhibitor, and the obtained product is clear Yellow transparent oily viscous liquid.

Embodiment 3

[0020] Example 3 Weigh 310 kg of aviation kerosene and add it to a stirring tank to raise the temperature to 50°C, add 345 kg of naphthenic acid imidazoline amide, 60 kg of benzotriazole, 60 kg of 2-picoline, and 175 kg of triethanolamine and stir for 1 hour Then add 50 kg of cetyl dimethyl benzyl ammonium bromide, stir for 2 hours, let it stand for 10 minutes, take a sample as a clear yellow liquid to obtain 1000 kg of the required corrosion inhibitor, and the obtained product is a clear yellow transparent oil Viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com