High glass transition temperature resin formulations

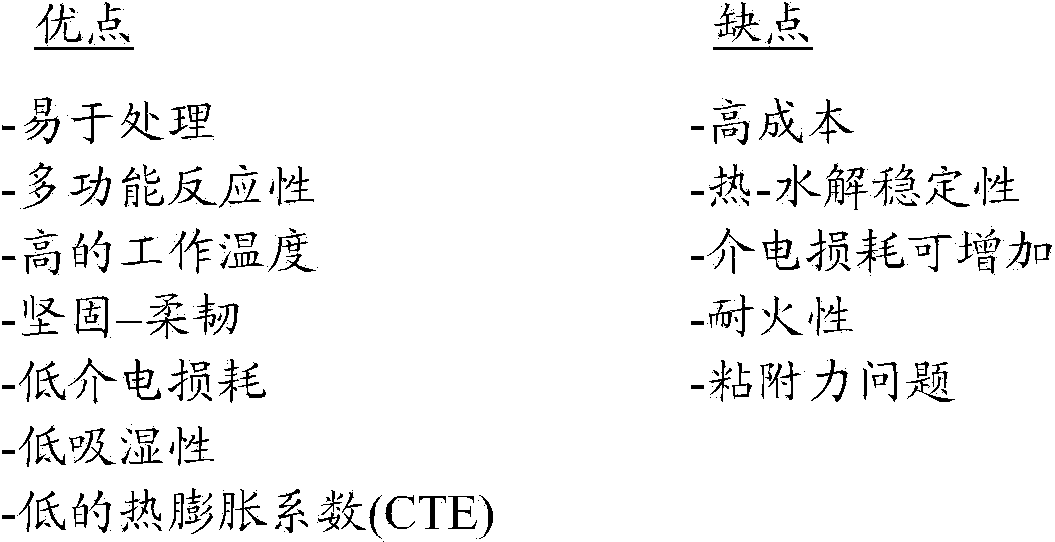

A technology for changing temperature and resin, which is applied in circuits, electrical solid state devices, semiconductor devices, etc., and can solve problems such as low heat-hydrolysis stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] Example 1 - Properties of Silsesquioxane Resin Components

[0053] Several different silsesquioxane resin components (described as resins 2, 4, 5, 6, and 7 in run numbers 1-8 of Table 3) were combined with several traditional silsesquioxanes according to the teachings of the present invention. Resin components (described as Resins 1, 3, 8, and 9 in Comparative Nos. B-E of Table 3) were prepared together. The molecular weight, total alkoxy and silanol content, and equivalent weight of phenolic hydroxyl groups measured for each silsesquioxane resin component are summarized in Table 3.

[0054] Table 3: Measured Properties of Silsesquioxane Resin Components .

[0055]

[0056] Referring to Table 3, each of the silsesquioxane resins (Resins 2 and 4-7) prepared according to the teachings of the present invention exhibited an equivalent weight of aromatic hydroxyl groups greater than 500 and less than 1,100 g / eq OH. In addition, these silsesquioxane resin components ...

example 2

[0057] Example 2 - Composition of Resin Formulation

[0058] Each of the silsesquioxane resin components described in Example 1 above (Resins 1-9) were used in the weight ratios shown in Table 4 below to form components comprising cyanate esters, optional cure accelerators ( such as a catalyst), and optionally a resin formulation comprising a solvent. Each component of the resin formulation was mixed in glass vials on a rotary wheel for 1 to 2 hours to form the resin formulations in Run Nos. 1-8 and Comparative Nos. A-E. The cyanates used to prepare these resin formulations are dicyanate monomers ( L-10, Huntsman Corporation), the cure accelerator was cobalt acetylacetonate, and the solvent was xylene.

[0059] Table 4: Composition of Resin Formulations

[0060]

[0061] Referring now to Table 3, the resin formulation described as Comparative No. A was made without the use of the silsesquioxane resin component and is representative of a conventional cyanate ester fo...

example 4

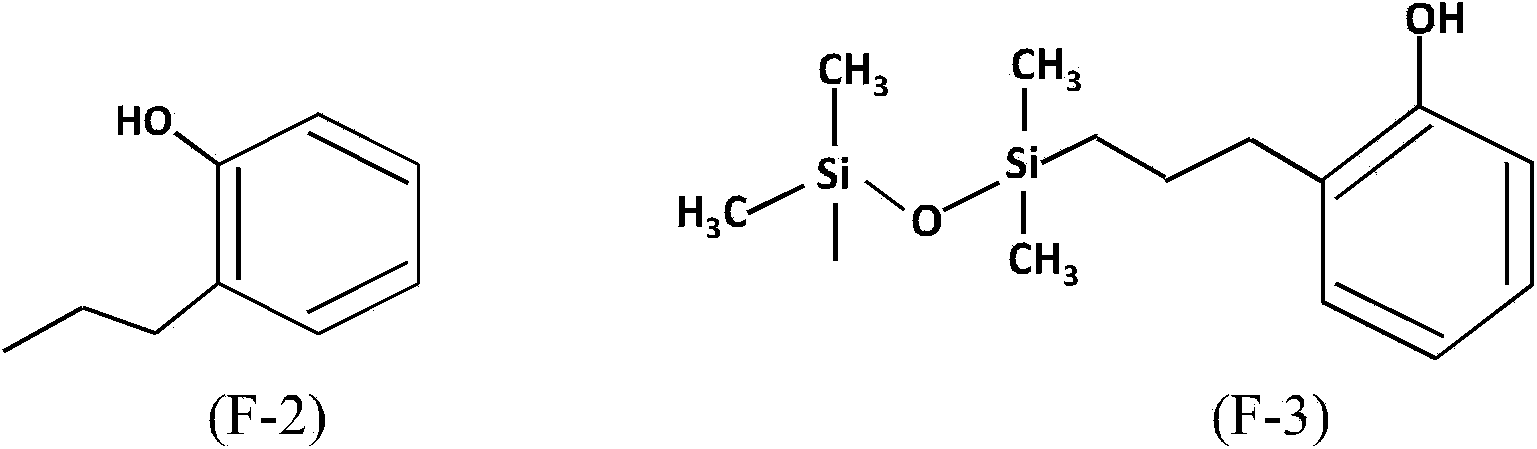

[0078] Example 4 - Preparation of Silsesquioxane Resin Components

[0079] Resin 1 - A 3 liter 3 neck round bottom flask was charged with phenyltrimethoxysilane (785.18g) and methyltrimethoxysilane (539.44g). The flask is equipped with Stirring paddle, thermometer, and Dean Stark apparatus attached to a water-cooled condenser. A total of 0.662 g, 390 uL of trifluoromethanesulfonic acid (FC-24, 3M Company) was added; then deionized water (186.28 g, 10.34 moles) was added slowly at room temperature. The temperature was increased to 71°C to distill off methanol (572.9 g). The reaction mixture was then cooled to 50°C and 248.30 g of tetramethyldisiloxane was added followed by glacial acetic acid (111.1 g). The reaction mixture was heated at 50 °C for 3 hours. The volatiles (177.5 g) were then distilled off by increasing the pot temperature to 70°C. Then n-heptane (439.7 g) was added to the reaction mixture. Wash the reaction mixture with deionized water (1 x 150 mL wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com