Preparation method of magnetic chitosan composite microsphere adsorbent

A technology of composite microspheres and chitosan, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of low density, poor mechanical properties, small and wide application, etc., and achieve high adsorption capacity , good thermal stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

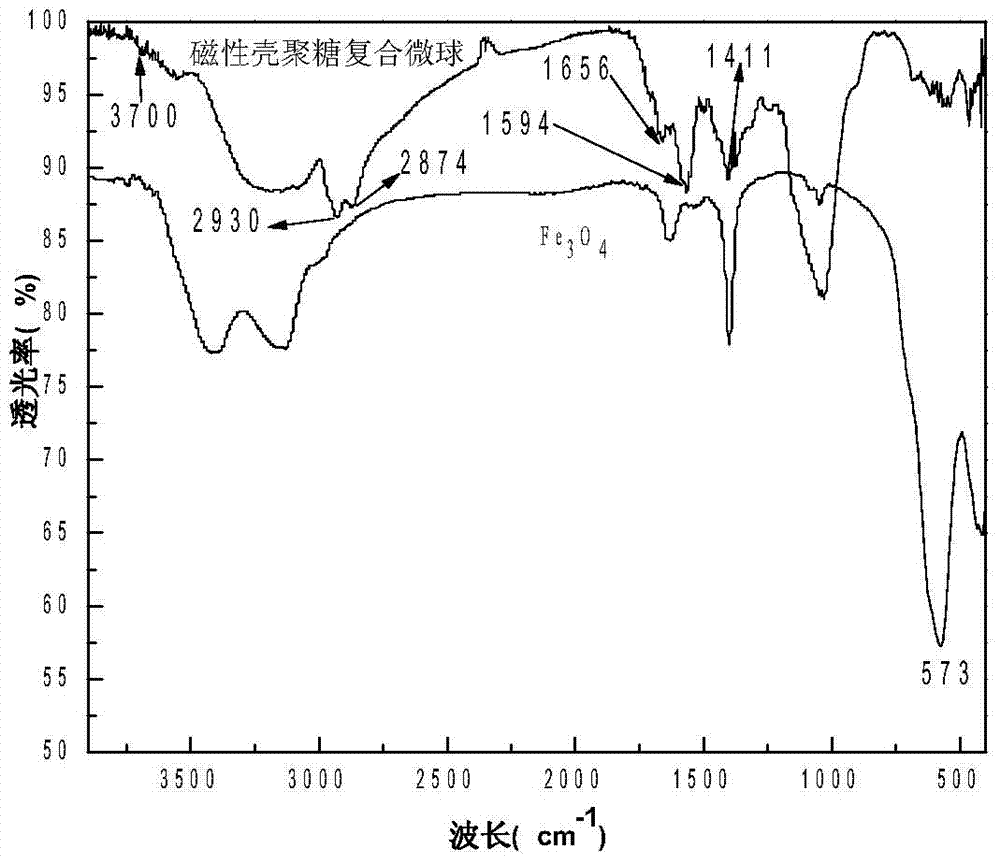

[0024] (1) Nano Fe 3 o 4 Synthesis;

[0025] 4.72g FeCl 3 ·6H 2 O and 1.72 g FeCl 2 4H 2 O was added to 96,6 mL of distilled water, followed by N 2 Stir mechanically under protection for 5-10 minutes to obtain a stable solution, then raise the temperature to 80°C, add concentrated ammonia water drop by drop, adjust the pH value of the solution to 10-11, react under vigorous stirring for 0.5-1.0 h, and wash the black product with Nd - Fe-B permanent magnet separation, the product is fully washed with distilled water until neutral, vacuum dried and ground at 50-60°C to obtain nano-Fe 3 o 4 .

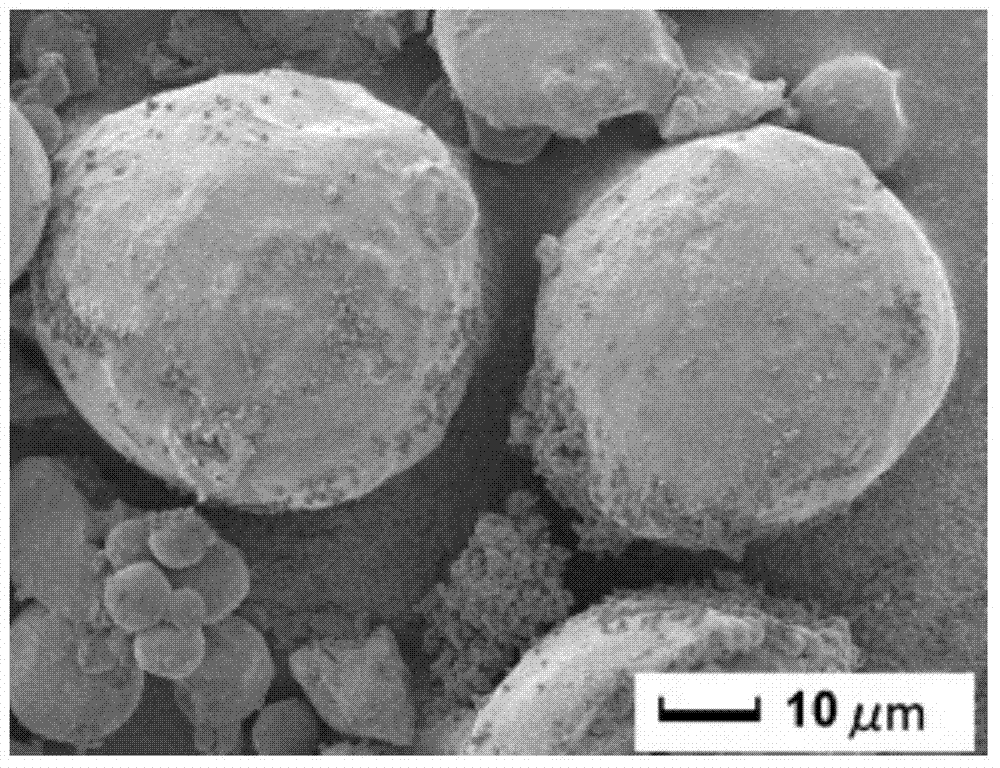

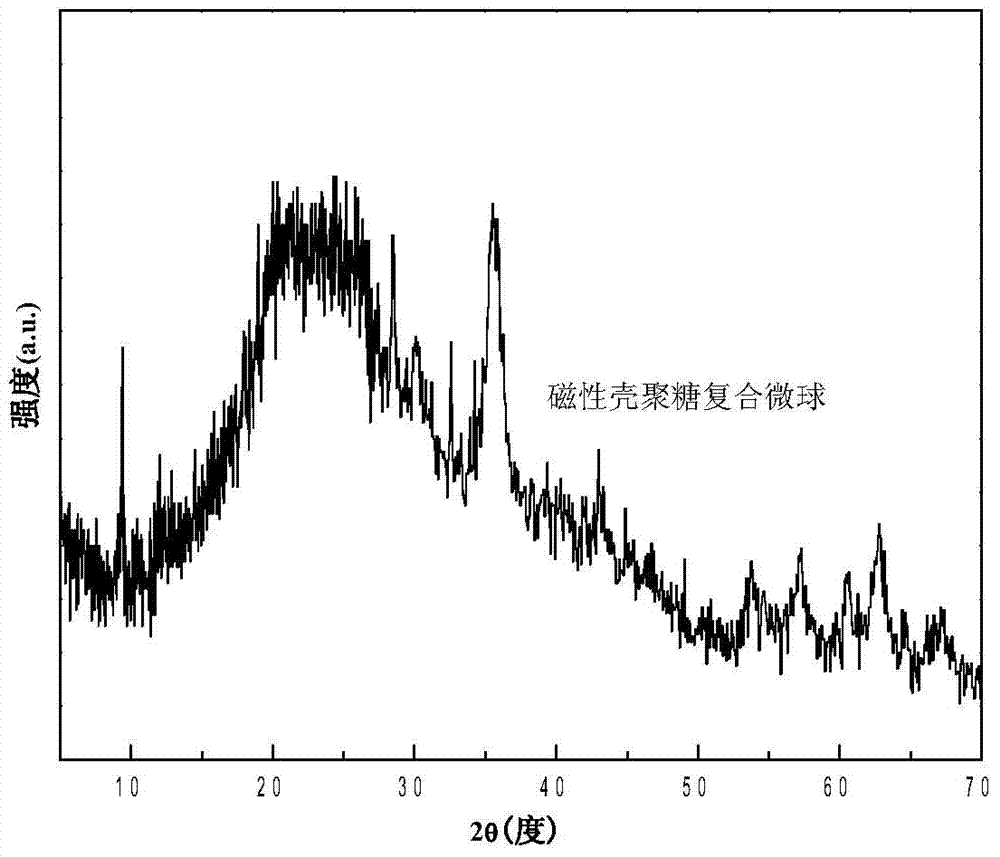

[0026] (2) Preparation of novel magnetic chitosan composite microsphere adsorbent;

[0027] 0.50 g of chitosan was added to 25 mL of 2 % acetic acid solution to form a stable solution under mechanical stirring, and 0.1 g of Fe 3 o 4 and 0.15g kaolin were added to the above solution, and mechanically stirred for 2 h; 100 mL liquid paraffin and 4 mL Span-80 were added to the above...

experiment example 1

[0036] Take 20 ml for an initial concentration of 120 mg L -1 Add the ciprofloxacin hydrochloride solution into the colorimetric tube, add 20 mg magnetic chitosan composite microsphere adsorbent, put the test solution at 25 o Stand in the water bath of C for 2, 4, 6, 8, 10, 20, 30, 40, 50 and 60 min, respectively. After the standing time was completed, the supernatant was separated and collected by a Nd-Fe-B permanent magnet, and the molecular concentration of unadsorbed ciprofloxacin hydrochloride was measured by an ultraviolet-visible spectrophotometer, and the adsorption capacity was calculated according to the result. Figure 5 It shows that the magnetic chitosan composite microspheres have good adsorption kinetics, and the adsorption equilibrium is basically reached within 60 minutes, and the adsorption rate is fast.

experiment example 2

[0038] Take 20ml and the initial concentration is 20, 40, 60, 80, 100, 120, 140, 160, 180 mg L -1 Add the ciprofloxacin hydrochloride solution into the colorimetric tube, add 20 mg magnetic chitosan composite microsphere adsorbent respectively, put the test solution at 25 o After standing in the water bath of C for 3.0 h, the supernatant was separated and collected by Nd-Fe-B permanent magnet, and the molecular concentration of unadsorbed ciprofloxacin hydrochloride was measured by UV-Vis spectrophotometer, and the adsorption capacity was calculated according to the results. Figure 6 It is shown that the saturated adsorption capacity of the magnetic chitosan composite microsphere adsorbent is 38.61 mg g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com