Preparation method of ultralong nanowire structure and nanoribbon structure copper calcium titanate

A technology of calcium copper titanate and nanowires, applied in the directions of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unseen dimensional nanowires and nanoribbon structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

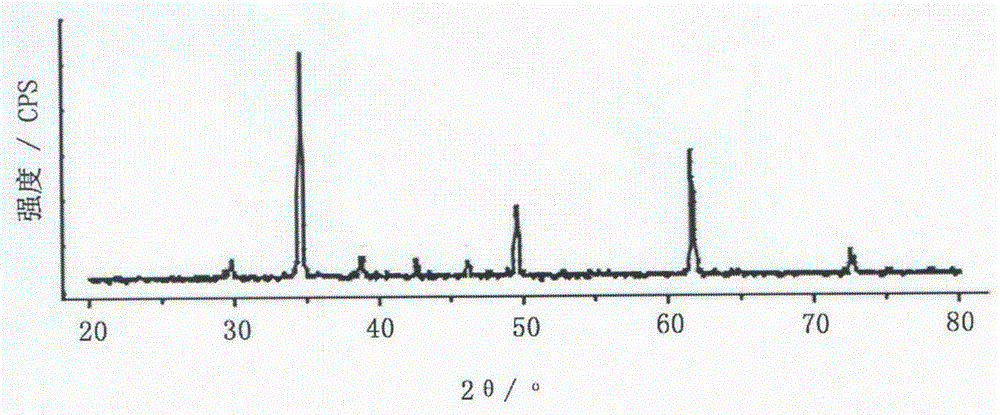

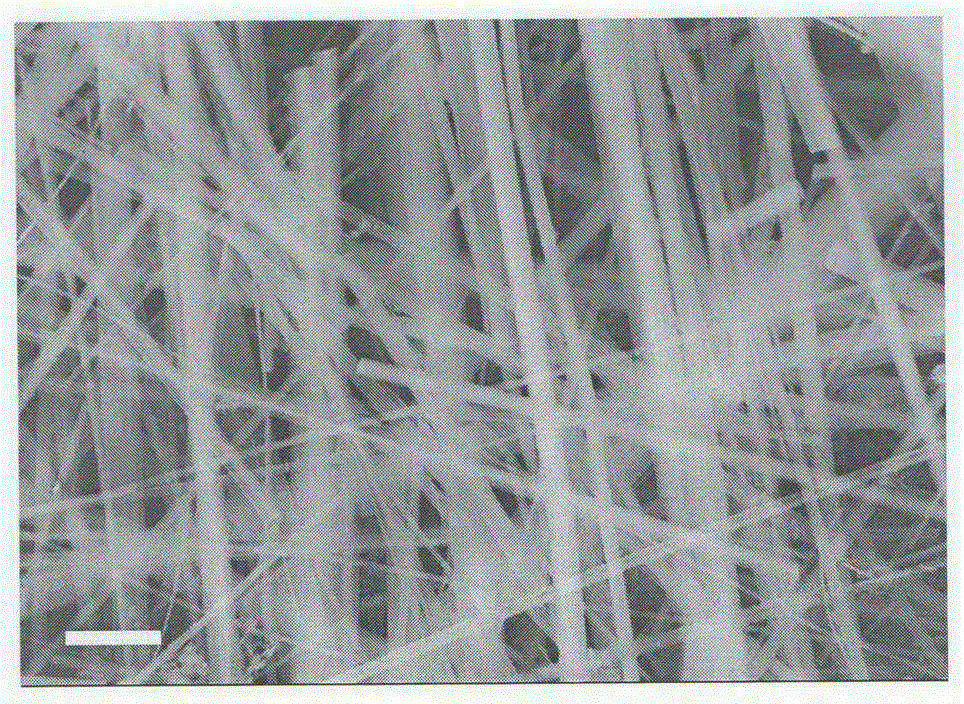

[0022] Preparation of ultra-long nanowire structure copper calcium titanate:

[0023] a, according to the chemical formula of calcium copper titanate CaCu 3 Ti 4 O 12 Weigh the mass of oxide raw materials as TiO 2 0.39g, CaO0.07g, CuO0.29g, and then weigh the salt masses as NaCl7.60g and KCl7.00g, put them in an agate ball mill tank and mill on the ball mill for 1 hour to make them evenly mixed;

[0024] b. Place the raw material mixture in step a in a corundum crucible for high-temperature reaction in a tube furnace, the reaction temperature is 650°C, and the reaction time is 4h;

[0025] c. Cool the sample obtained in step b to room temperature with the furnace, add deionized water to wash, filter, remove molten salt, and then clean it under 10kHz ultrasonic action to remove impurities, and then place the sample in a dry box at a temperature of 60 After drying at ℃ for 5 hours, the target product, ultra-long nanowire structure, copper calcium titanate, CaCu, is obtained 3 Ti 4 O 12...

Embodiment 2

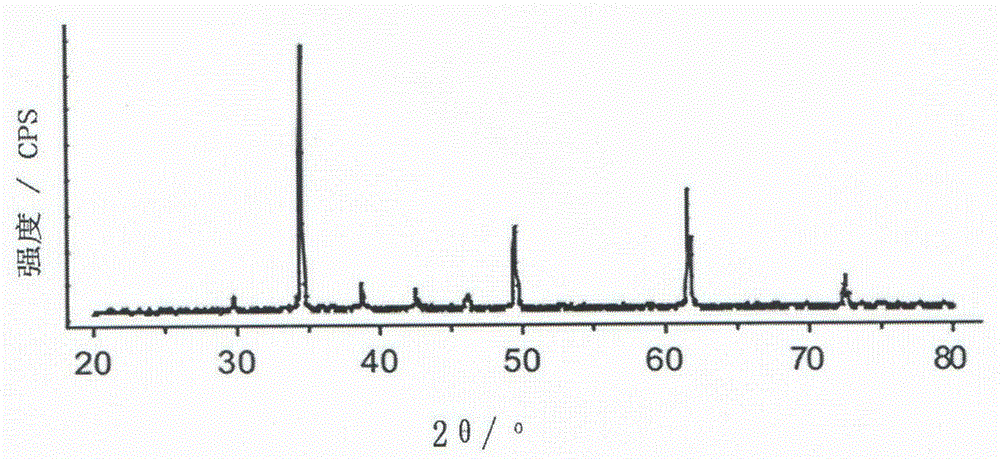

[0027] Preparation of ultra-long nanobelt structure copper calcium titanate:

[0028] a, according to the chemical formula of calcium copper titanate CaCu 3 Ti 4 O 12 Weigh the mass of oxide raw materials as TiO 2 0.39g, CaO0.07g, CuO0.29g, and then weigh the salt masses as NaCl7.60g and KCl7.00g, put them in an agate ball mill tank and mill on the ball mill for 1 hour to make them evenly mixed;

[0029] b. Place the raw material mixture in step a in a corundum crucible for high-temperature reaction in a tube furnace, the reaction temperature is 850°C, and the reaction time is 4h;

[0030] c. Cool the sample obtained in step b to room temperature with the furnace, add deionized water to wash, filter, remove molten salt, and then clean it under 10kHz ultrasonic action to remove impurities, and then place the sample in a dry box at a temperature of 60 After drying at ℃ for 5 hours, the target product, ultra-long nanobelt structure copper calcium titanate CaCu 3 Ti 4 O 12 .

Embodiment 3

[0032] Preparation of ultra-long nanowire structure copper calcium titanate:

[0033] a, according to the chemical formula of calcium copper titanate CaCu 3 Ti 4 O 12 Weigh the mass of oxide raw materials as TiO 2 0.78-3.90g, CaO0.14g, CuO0.58g, and weigh the salt mass as NaCl14.05g and KCl13.25g into an agate mortar and ball mill on a ball mill for 3h to make it evenly mixed;

[0034] b. Place the raw material mixture in step a in a corundum crucible for high-temperature reaction in a tube furnace, the reaction temperature is 700°C, and the reaction time is 5 hours;

[0035] c. Cool the sample obtained in step b to room temperature with the furnace, add deionized water to wash, filter, remove molten salt, and then clean twice under the action of 30kHz ultrasound to remove impurities, and then place the sample in a dry box at a temperature of 60 After drying at ℃ for 5 hours, the target product, ultra-long nanowire structure, copper calcium titanate, CaCu, is obtained 3 Ti 4 O 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com