Production technology of metal molybdenum

A production process and metal technology, applied in the production process field of metal molybdenum, can solve the problems of high energy consumption, hidden safety hazards and high temperature, and achieve the effects of low production cost, high production efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using MoO 3 As raw material, its technological process is:

[0021] Weigh 100Kg of MoO 3 Powder, 39.4Kg aluminum powder, 30Kg calcium fluoride powder, all required to be powders below 100 mesh, mixed in the mixer for 2 hours; then put the mixed powder into the reaction vessel (reaction furnace made of refractory material) During the charging process, the material is compacted, and then the reaction vessel is evacuated until the vacuum reaches 10 -1 After Pa, the material is ignited by resistance heating, so far the aluminothermic reduction reaction starts to proceed automatically by the heat released by itself, and the reaction is completed within 3 minutes. After natural cooling, the metal layer is separated from the slag, and the primary alloy is obtained. The primary alloy is broken into particles less than 3cm, and the metal molybdenum is obtained by melting twice in a vacuum electron beam furnace, and the melting power is 260kW; the chemical composition of the me...

Embodiment 2

[0023] Using MoO 2 As raw material, its technological process is:

[0024] Weighing 100Kg MoO 2 powder, 29.5Kg aluminum powder, 20Kg calcium fluoride powder, powder below 100 mesh is required, mixed in the mixer for 2 hours; ), the material is compacted during the charging process, and then the reaction vessel is evacuated until the vacuum reaches 10 -1 After Pa, the material is ignited by resistance heating, and the aluminothermic reduction reaction starts to proceed automatically by the heat released by itself, and the reaction is completed within 3 minutes. After natural cooling, the metal layer is separated from the slag, and the primary alloy is obtained. The primary alloy is crushed into particles smaller than 3cm, and then melted twice in a vacuum electron beam furnace to obtain metal molybdenum, and the melting power is 260kW.

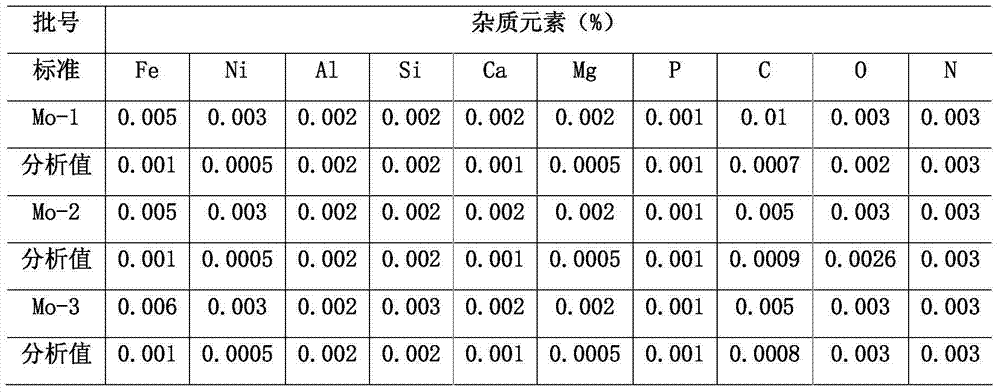

[0025] Table 1:

[0026]

[0027] Table 1 above shows the analysis results of molybdenum metal. It can be seen that the metal molybden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com