Spherical spinel lithium titanate and preparation method and application thereof

A lithium titanate and spinel technology, which is applied in the field of spherical spinel lithium titanate and its preparation, can solve the problem that the chemical composition and morphology are difficult to precisely control, the tap density of lithium titanate materials is small, and the slurry treatment and Coating difficulties and other problems, to avoid decomposition or the formation of protective film, excellent cycle performance, excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

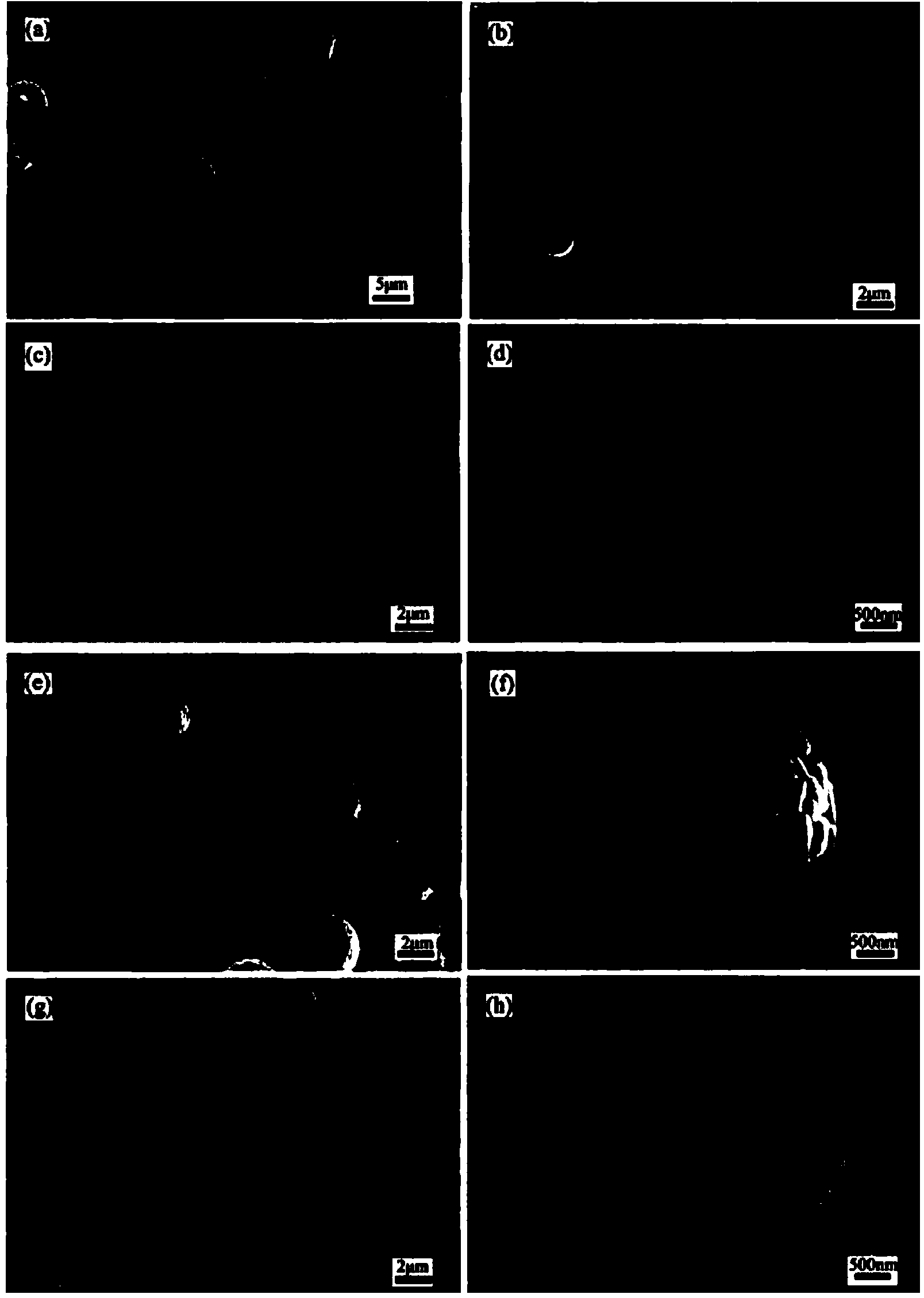

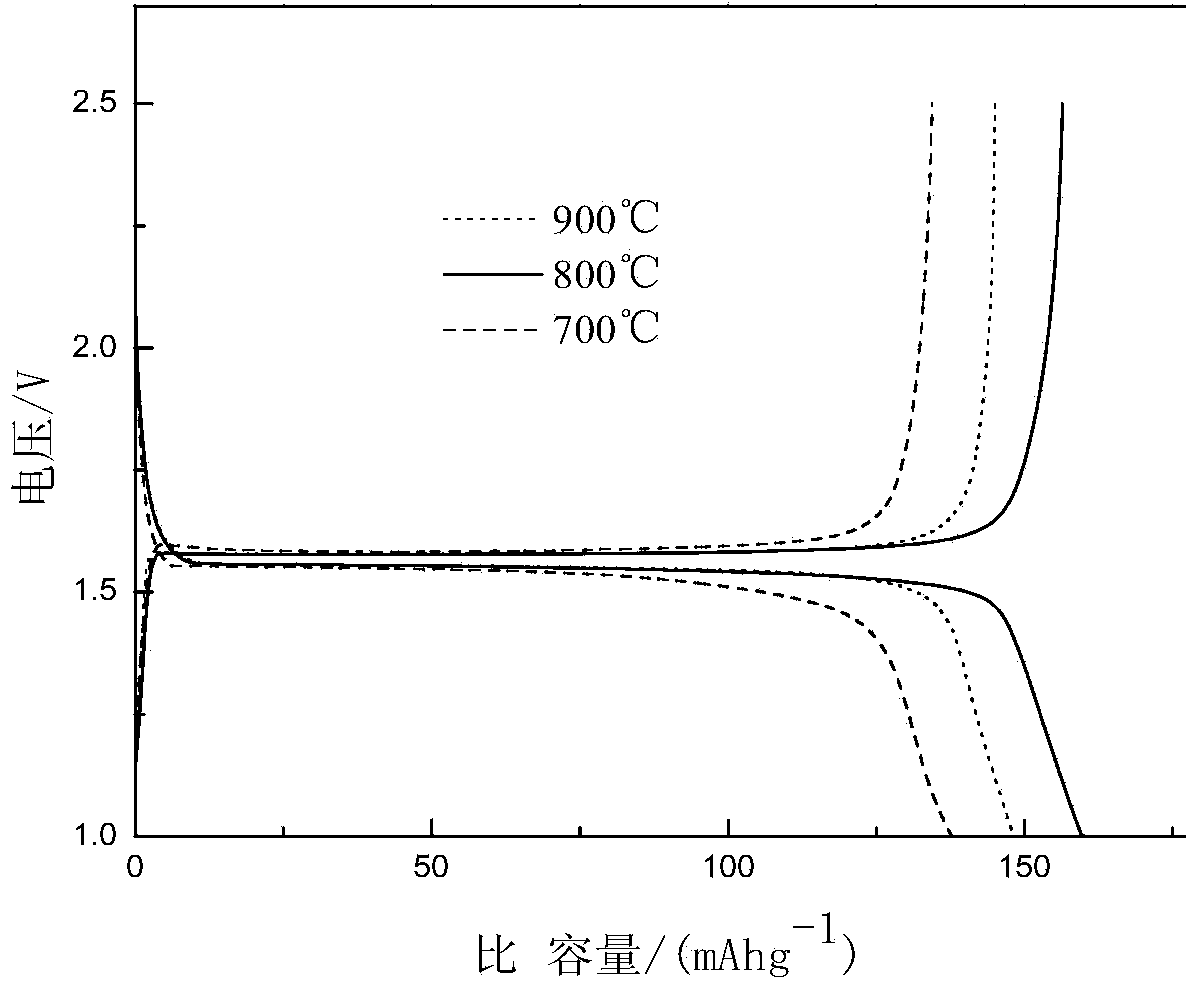

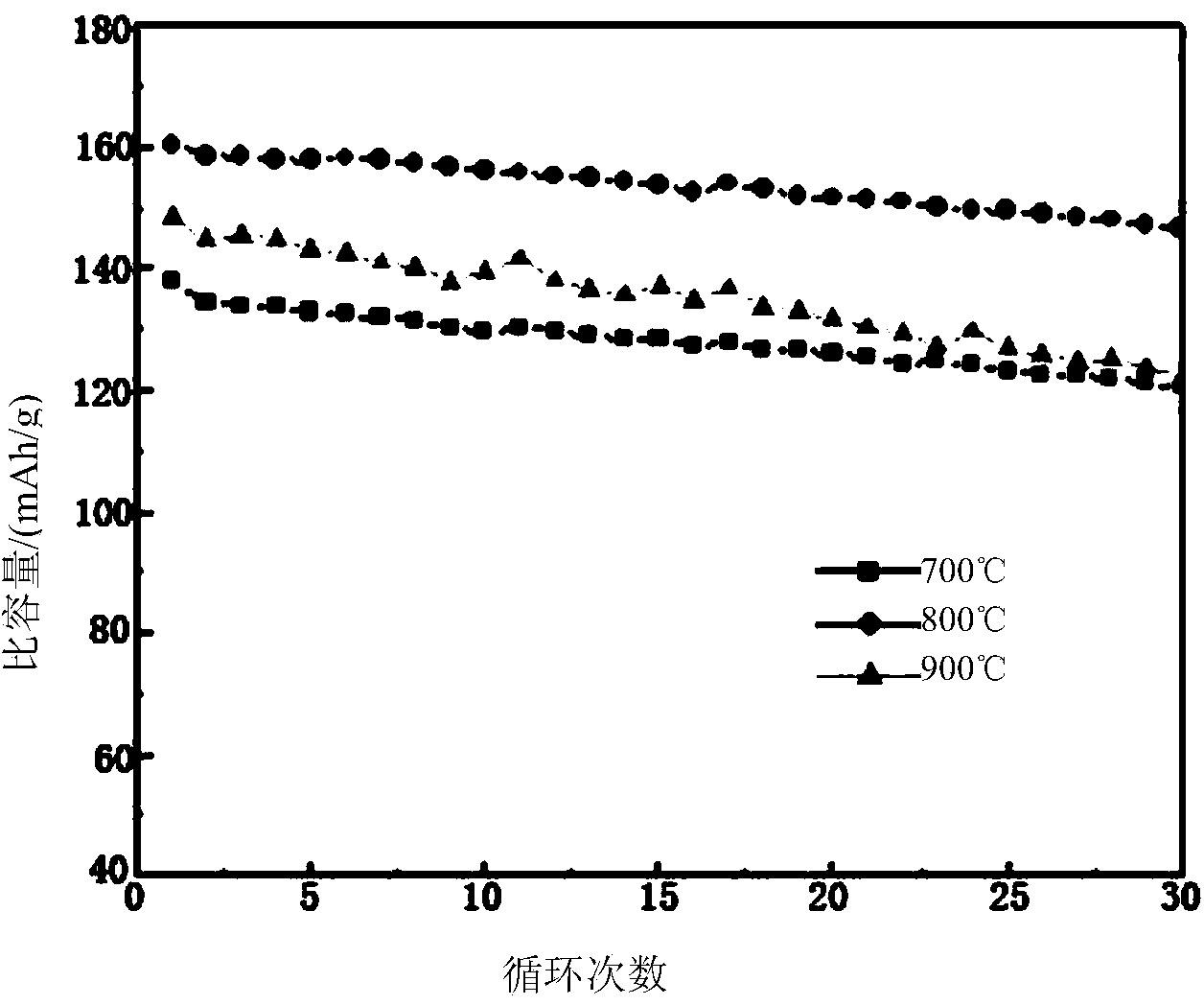

Embodiment 1

[0030] (1) Dissolve 5g of cetyltrimethylammonium bromide and 45g of lithium acetate in 40g of absolute ethanol successively to obtain a mixed solution;

[0031] (2) 45g of butyl titanate was slowly added dropwise to the mixed solution under 1200rpm magnetic stirring to form a yellow transparent solution, and continued to stir for 12 hours to form a yellow transparent sol;

[0032] (3) aging the yellow transparent sol in the air for 1 to 3 days to form a white gel, and drying the obtained white gel in the air at 100°C for 24 hours to form a xerogel precursor;

[0033] (4) After grinding the dry gel precursor, pre-calcine at 700° C. for 4 hours, and heat-treat at 900° C. for 12 hours to obtain spherical spinel lithium titanate 1 .

Embodiment 2

[0035] (1) Dissolve 15g of cetyltrimethylammonium bromide and 30g of lithium acetate in 65g of absolute ethanol successively to obtain a mixed solution;

[0036] (2) 25g of butyl titanate was slowly added dropwise to the mixed solution under 2000rpm magnetic stirring to form a yellow transparent solution, and continued to stir for 12 hours to form a yellow transparent sol;

[0037] (3) aging the yellow transparent sol in the air for 1 to 3 days to form a white gel, and drying the obtained white gel in the air at 100°C for 24 hours to form a xerogel precursor;

[0038] (4) After the dry gel precursor is ground, pre-calcined at 800°C for 4h, and heat-treated at 700°C for 12h to obtain spherical spinel lithium titanate 2.

Embodiment 3

[0040] (1) Dissolve 10g of cetyltrimethylammonium bromide and 35g of lithium acetate in 50g of absolute ethanol successively to obtain a mixed solution;

[0041] (2) Slowly add 30 g of butyl titanate into the mixed solution under magnetic stirring at 1500 rpm to form a yellow transparent solution, and continue stirring for 12 hours to form a yellow transparent sol;

[0042] (3) aging the yellow transparent sol in the air for 1 to 3 days to form a white gel, and drying the obtained white gel in the air at 100°C for 24 hours to form a xerogel precursor;

[0043] (4) After grinding the dry gel precursor, pre-calcine at 900° C. for 4 hours, and heat-treat at 800° C. for 12 hours to obtain spherical spinel lithium titanate 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com