Preparation method of lithium vanadyl phosphate lithium vanadyl phosphate positive electrode material of lithium ion battery with core-shell structure

A lithium-ion battery, lithium vanadyl phosphate technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of limited electrochemical performance, low electronic conductivity, violent chemical reaction, etc., and achieve excellent electrochemical performance. , the effect of improving electrical conductivity and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

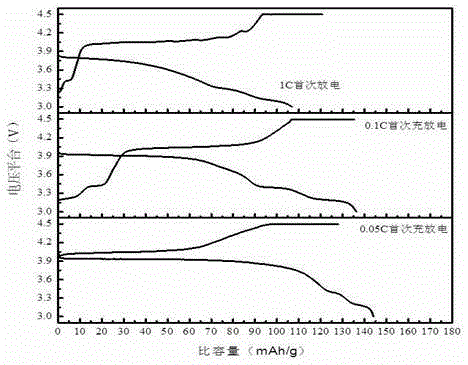

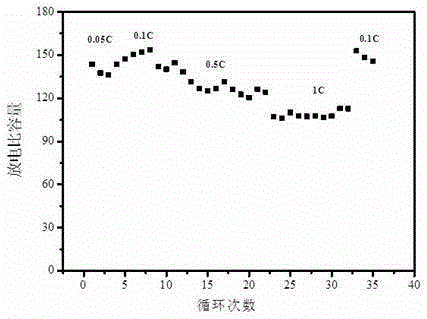

Embodiment 1

[0023] Weigh 0.01mol of lithium fluoride, 0.005mol of vanadium pentoxide, 0.01mol of diammonium hydrogen phosphate, and 0.02mol of citric acid, dissolve them in 500mL of deionized water to form a uniform blue solution, and adjust the pH of the solution to 7 Transfer the solution to a high-pressure reactor, heat and react at 250°C for 12 hours to obtain a uniform sol, take out the obtained sol and filter, and dry the filtered product in a vacuum oven at 80°C; grind the dried powder in an agate mortar After that, put it in a sintering furnace, sinter at 450°C for 8h in an air atmosphere, then heat-treat at 350°C for 1h in an oxygen atmosphere, and finally cool down to room temperature naturally to obtain vanadium pentoxide-coated lithium ions with a core-shell structure. Battery cathode material lithium vanadyl phosphate.

[0024] Battery assembly: Weigh 0.24g of the obtained lithium vanadyl phosphate positive electrode material, add 0.03g Super-P as a conductive agent and 0.03g...

Embodiment 2

[0026] Weigh 0.02mol of lithium hydroxide, 0.01mol of vanadium pentoxide, 0.02mol of diammonium hydrogen phosphate, and 0.02mol of citric acid, and dissolve them together in 500mL of deionized water to form a uniform green solution, and adjust the pH of the solution to 6; Transfer the solution to a high-pressure reactor, heat and react at 300°C for 10 hours to obtain a homogeneous sol; take out the obtained sol and filter, and dry the filtered product in a vacuum oven at 120°C; grind the dried powder in an agate mortar , placed in a sintering furnace, sintered at 500°C for 15h in an argon atmosphere, then heat-treated at 200°C for 4h in an oxygen atmosphere, and finally cooled to room temperature naturally, that is, lithium vanadyl phosphate lithium ion battery cathode material with a core-shell structure .

[0027] Battery assembly: Weigh 0.24g of the obtained lithium vanadyl phosphate positive electrode material, add 0.03g Super-P as a conductive agent and 0.03g PVDF (HSV-90...

Embodiment 3

[0029] Weigh 0.05 mol of lithium fluoride, 0.05 mol of ammonium metavanadate, 0.05 mol of diammonium hydrogen phosphate, and 0.2 mol of citric acid, and dissolve them together in 2000 mL of deionized water to form a uniform green solution, and adjust the pH of the solution to 9; Then transfer the solution to a high-pressure reactor, heat and react at 200°C for 72 hours to obtain a reverse homogeneous sol; take out the obtained sol and filter, and dry the filtered product in a vacuum oven at 60°C; dry the dried powder in an agate mortar After grinding, place it in a sintering furnace, sinter at 300°C for 6h in an air atmosphere, then heat-treat at 400°C for 0.1h in an oxygen atmosphere, and finally cool down to room temperature naturally to obtain the lithium-ion battery cathode material oxygen phosphate with a core-shell structure. Lithium vanadium.

[0030] Battery assembly: Weigh 0.24g of the obtained lithium vanadyl phosphate positive electrode material, add 0.03g Super-P a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com