Nano silver catalyst for catalyzing hydrolysis of amino borane and preparation method thereof

A technology of aminoborane and nano-silver, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of few synthesis methods of nano-tetrametallic core-shell structures, etc. problem, achieve the effect of preventing aggregation, reducing cost and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

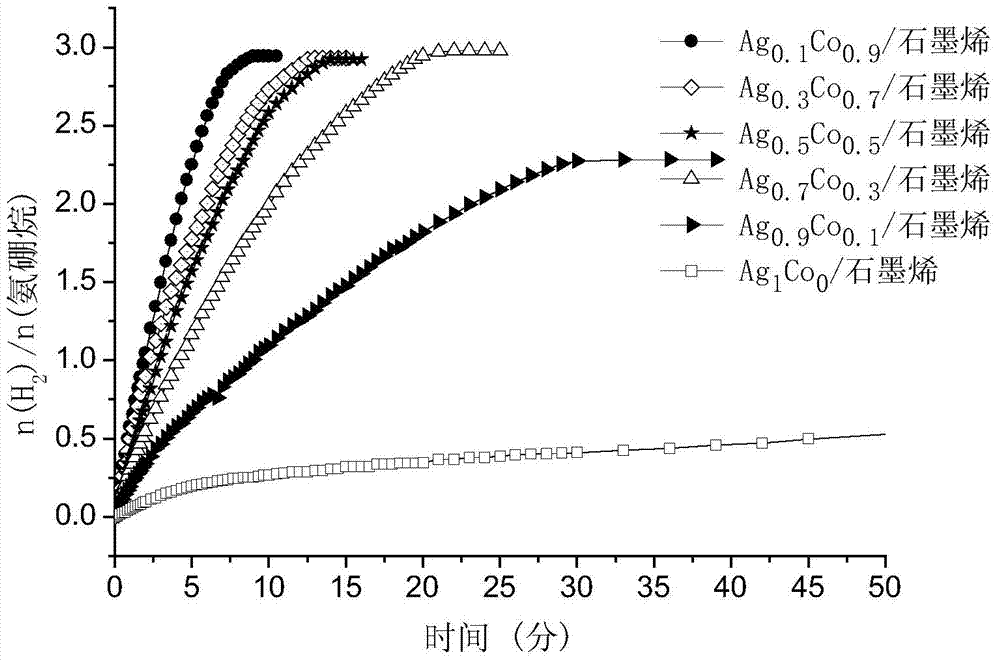

[0043] Preparation of nano-Ag with different x values x co 1-x / graphene catalyst, where the molar ratio of Ag to Co is x:1-x, 0.1≤x≤0.9, a total of five sets of experiments.

[0044] Silver nitrate solution and cobalt chloride solution with concentrations of 0.05mol / L and 0.0225mol / L were prepared respectively. Take silver nitrate solution and cobalt chloride solution in a flask, add 10 mg of graphene oxide as a loading agent, after ultrasonic dispersion, add 2 mmol of reducing agent methylamine borane under electromagnetic stirring, and fully react at 25°C , to get nano-Ag x co 1-x / graphene catalyst, the addition of silver nitrate solution and cobalt chloride solution of five groups of experiments is as shown in table 1.

[0045] The addition of silver nitrate solution and cobalt chloride solution of five groups of experiments of table 1

[0046]

[0047] At the same time, the Ag / graphene catalyst was prepared, and 1.0 mL of silver nitrate solution with a concentr...

Embodiment 2

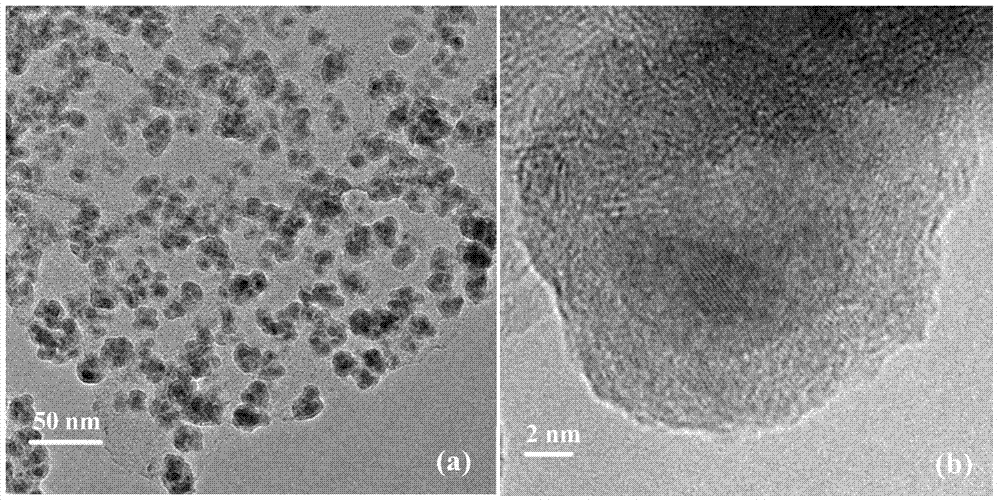

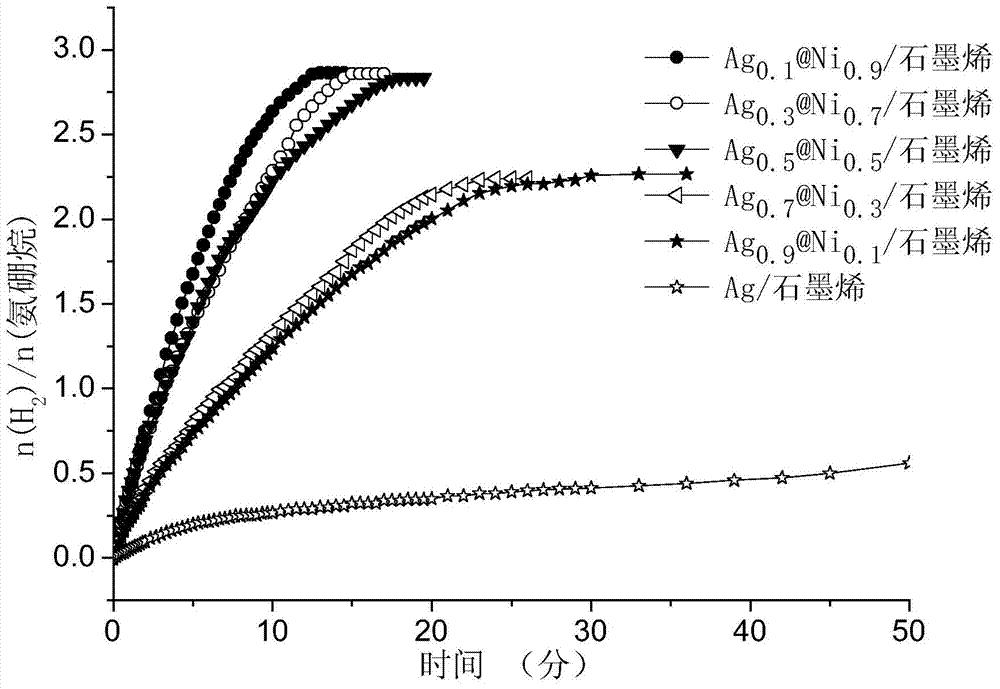

[0050] Preparation of nano-Ag with different x values x Ni 1-x / Graphene catalyst, wherein the molar ratio of Ag to Ni is x:1-x, x is 0.1≤x≤0.9, a total of five sets of experiments.

[0051] Silver fluoride solution and nickel acetate solution with concentrations of 0.05mol / L and 0.0225mol / L were prepared respectively. Take silver fluoride solution and nickel acetate solution in a flask, add 10 mg of graphene oxide as a loading agent, after ultrasonic dispersion, add 2 mmol of reducing agent methylamine borane under electromagnetic stirring, and fully react at 25 °C , to get nano-Ag x Ni 1-x / graphene catalyst. The addition amount of silver fluoride solution and nickel acetate solution of five groups of experiments is shown in Table 2.

[0052] The addition of silver fluoride solution and nickel acetate solution of five groups of experiments of table 2

[0053]

[0054] At the same time, the Ag / graphene catalyst was prepared, and 1.0 mL of silver fluoride solution wi...

Embodiment 3

[0057] Preparation of nano-Ag with different x values x Fe 1-x / Graphene catalyst, wherein the molar ratio of Ag to Fe is x:1-x, x is 0.1≤x≤0.9, a total of five sets of experiments.

[0058] Silver perchlorate and ferric nitrate are prepared into solutions, the concentrations of which are 0.05mol / L and 0.0225mol / L respectively. Take silver perchlorate solution and ferric nitrate solution in a flask, add 10 mg of graphene oxide as a loading agent, after ultrasonic dispersion is uniform, add 2 mmol of reducing agent methyl ammonia borane under electromagnetic stirring, at 25 ° C Fully react to get nano-Ag x Fe 1-x / graphene catalyst, the addition of silver perchlorate solution and ferric nitrate solution of five groups of experiments is as shown in table 3.

[0059] The addition of silver perchlorate solution and iron nitrate solution of five groups of experiments of table 3

[0060]

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com