A kind of preparation method of graphene-supported tin-nickel nano-alloy particle composite material

A nano-alloy and composite material technology, applied in the field of materials, can solve problems that do not conform to the characteristics of general composite materials, and achieve the effects of stable product shape, uniform heating, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

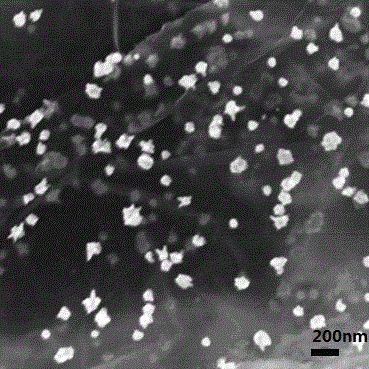

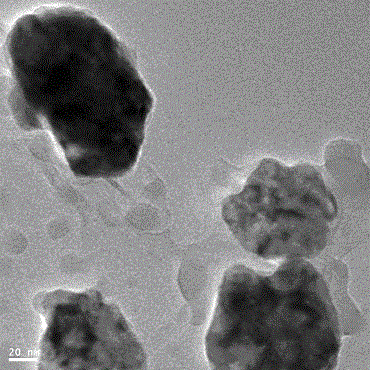

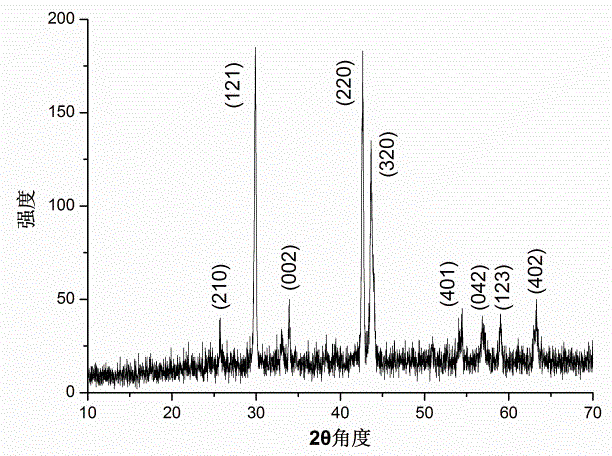

Image

Examples

Embodiment 1

[0046] 1) Synthesis of graphite oxide by Hummers method

[0047] In the first step, weigh 1g of natural flake graphite and 0.5g of sodium nitrate, add them into a 250mL three-neck round bottom flask, and then slowly add 24ml of concentrated sulfuric acid. The reaction process of the system was mechanically stirred in an ice-water bath;

[0048] In the second step, 2 g of potassium permanganate is slowly added during the stirring process, and the reaction temperature is controlled within 10±2° C. by adjusting the adding speed. After the addition is complete, continue to stir at low temperature for 0.5~2h;

[0049] The third step is to replace the ice-water bath with an oil bath for heating, control the temperature at 35±3°C, and continue to stir for 5~24h;

[0050] In the fourth step, slowly add 48mL deionized water several times for dilution;

[0051] Step 5: After stirring for 0.5h, add 70mL of deionized water at 60°C, and add 5~10mL of 30% hydrogen peroxide. At this time,...

Embodiment 2

[0062] In the first step, weigh 1g of natural flake graphite and 1g of sodium nitrate, add them into a 250mL three-neck round bottom flask, and then slowly add 24ml of concentrated sulfuric acid. The reaction process of the system was mechanically stirred in an ice-water bath;

[0063] In the second step, 3 g of potassium permanganate is slowly added during the stirring process, and the reaction temperature is controlled within 10±2° C. by adjusting the adding speed. After the addition is complete, continue to stir at low temperature for 0.5~2h;

[0064] The third step is to replace the ice-water bath with an oil bath for heating, control the temperature at 35±3°C, and continue to stir for 5~24h;

[0065] In the fourth step, slowly add 48mL deionized water several times for dilution;

[0066] Step 5: After stirring for 0.5h, add 70mL of deionized water at 60°C, and add 5~10mL of 30% hydrogen peroxide. At this time, the reaction product will quickly turn bright yellow;

[00...

Embodiment 3

[0076] In the first step, weigh 1g of natural flake graphite and 2g of sodium nitrate, add them into a 250mL three-neck round bottom flask, and then slowly add 24ml of concentrated sulfuric acid. The reaction process of the system was mechanically stirred in an ice-water bath;

[0077] In the second step, slowly add 2~5g of potassium permanganate during the stirring process, and control the reaction temperature within 10±2°C by adjusting the adding speed. After the addition is complete, continue to stir at low temperature for 0.5~2h;

[0078] The third step is to replace the ice-water bath with an oil bath for heating, control the temperature at 35±3°C, and continue to stir for 5~24h;

[0079] In the fourth step, slowly add 48mL deionized water several times for dilution;

[0080] Step 5: After stirring for 0.5h, add 70mL of deionized water at 60°C, and add 5~10mL of 30% hydrogen peroxide. At this time, the reaction product will quickly turn bright yellow;

[0081] Step 6: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com