Broad-spectrum efficient antibacterial amino molding material

An amino molding compound, high-efficiency technology, applied in the field of broad-spectrum high-efficiency antibacterial amino molding compound, to achieve good antibacterial effect, improve mechanical strength, and good miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

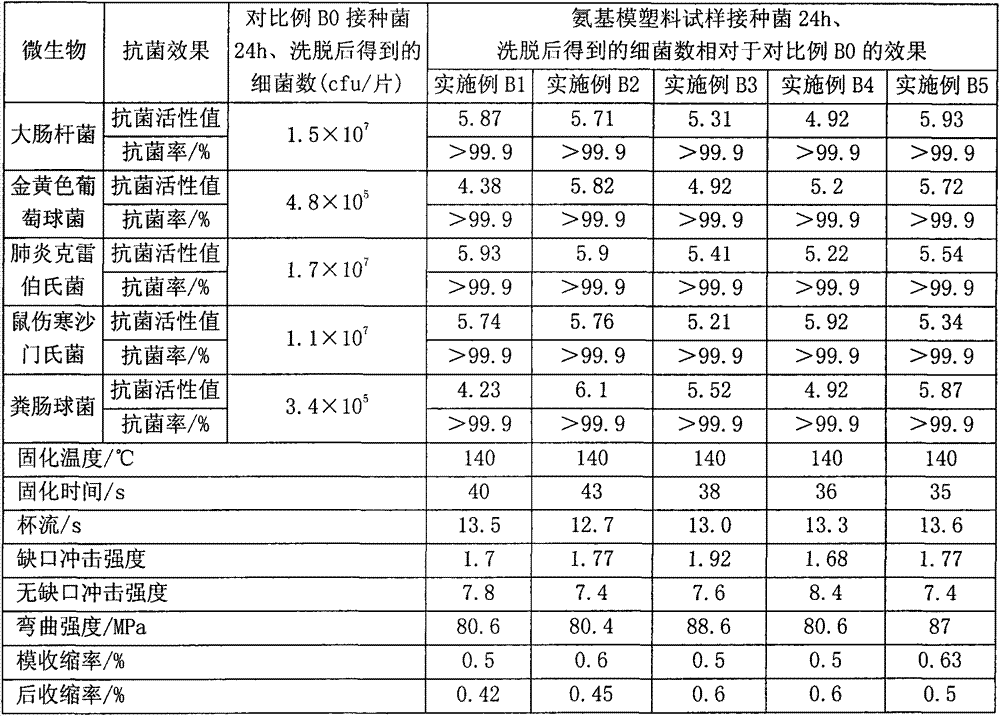

Examples

Embodiment A1

[0034] (1) Add 30 parts of water into the reaction kettle, then add 20 parts of neopentyl glycol, heat to 40°C, add 0.6 parts of hexamethylene tetraamine to adjust the pH to 8.5±0.1, and obtain buffered neopentyl glycol Joint agent solution;

[0035] (2) Keep the reactor at 40°C, add 2 parts of active nano-zinc oxide and 30 parts of nano-rutile titanium dioxide to the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25min, and cool to At room temperature, a composite antibacterial agent is obtained through infiltration and coupling, that is, neopentyl glycol / zinc oxide / titanium dioxide nanocomposite antibacterial agent.

Embodiment A2

[0037] (1) Add 35 parts of water into the reaction kettle, then add 25 parts of neopentyl glycol, heat to 40°C, add 0.7 parts of hexamethylene tetraamine to adjust the pH to 8.5±0.1, and obtain buffered neopentyl glycol Joint agent solution;

[0038] (2) Keep the reactor at 40°C, add 10 parts of active nano-zinc oxide and 30 parts of nano-rutile titanium dioxide to the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25min, and cool to At room temperature, a composite antibacterial agent is obtained through infiltration and coupling, that is, neopentyl glycol / zinc oxide / titanium dioxide nanocomposite antibacterial agent.

Embodiment A3

[0040] (1) Add 30 parts of water into the reaction kettle, then add 25 parts of neopentyl glycol, heat to 40°C, add 0.5 parts of hexamethylenetetramine to adjust the pH to 8.5±0.1, and obtain buffered neopentyl glycol Joint agent solution;

[0041] (2) Keep the reactor at 40°C, add 10 parts of zinc sulfate and 30 parts of nano-rutile titanium dioxide to the buffered neopentyl glycol solution, control the temperature of the material at 45°C, stir for 25min, and cool to room temperature through the jacketed water of the reactor. The composite antibacterial agent is obtained through infiltration and coupling, that is, neopentyl glycol / zinc sulfate / titanium dioxide nanocomposite antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com