Graphene-titanium diboride oxide compound and preparation method thereof

A diboron oxide and graphene technology, applied in chemical instruments and methods, dyeing organic silicon compound treatment, dyeing low molecular organic compound treatment and other directions, can solve problems such as deteriorating the manufacturability of composite materials, achieve low cost, improve dielectric Constant, the effect of reducing the conductance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of titanium diboride oxide

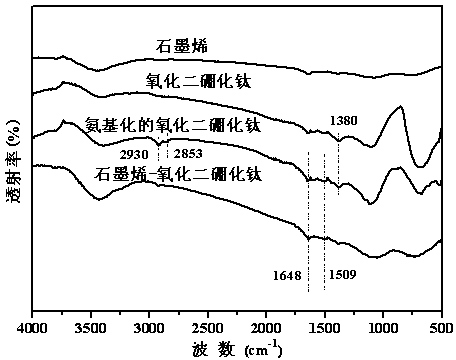

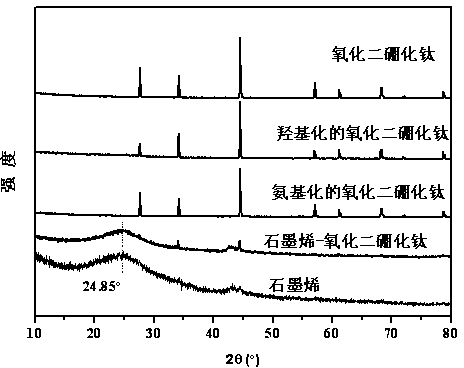

[0036] Under aerobic conditions, oxidize 10 g of titanium diboride with a particle size of less than 200 nanometers at 600 ° C for 10 minutes to obtain a crude product, disperse it in 200 mL of ethanol, stir it, filter it with suction, and dry it to obtain oxidized titanium diboride . The infrared spectrogram and X-ray diffraction figure of the prepared oxide titanium diboride are respectively referred to in the attached figure 1 and 2 .

[0037] 2. Preparation of aminated titanium diboride oxide

[0038] Disperse 10g of titanium diboride oxide into 50mL of hydrogen peroxide solution with a mass fraction of 35%, and react at 100°C for 5h; after the reaction, wash, filter with suction, and dry in a vacuum oven at 60°C for 12h to obtain Hydroxylated titanium diboride oxide;

[0039] Add 10 g of hydroxylated oxidized titanium diboride to 100 mL of absolute ethanol, mix well by ultrasonic, add 0.1 g of γ-aminopropyltriethoxys...

Embodiment 2

[0049] Preparation of Graphene-Titanium Diboride Oxide Composite

[0050] Weigh 1g of graphite oxide and disperse it in 600mL N,N-dimethylformamide, stir and sonicate for 1h to obtain a graphene oxide dispersion, add 0.025g of aminated titanium diboride oxide to the graphene oxide dispersion , ultrasonically stirred, reacted at 60°C for 12h, then added 10g L-ascorbic acid, raised the temperature of the reaction solution to 90°C and reacted for 24h, then filtered, washed, and dried to obtain a graphene-titanium diboride oxide composite , wherein the content of titanium diboride oxide is 0.05 times the mass of graphene. Its 25 thousand times magnified scanning electron microscope picture and X-ray diffraction picture are respectively shown in the attached image 3 and 4 .

Embodiment 3

[0052] Preparation of Graphene-Titanium Diboride Oxide Composite

[0053] Weigh 1g of graphite oxide and disperse it in 600mL N,N-dimethylformamide, stir and sonicate for 1h to obtain a graphene oxide dispersion, add 0.5g of aminated titanium diboride oxide to the graphene oxide dispersion , ultrasonically stirred, reacted at 60°C for 12h, then added 10g L-ascorbic acid, raised the temperature of the reaction solution to 90°C and reacted for 24h, then filtered, washed, and dried to obtain a graphene-titanium diboride oxide composite , wherein the content of titanium diboride oxide is the same as that of graphene. Its 25 thousand times magnified scanning electron microscope picture and X-ray diffraction picture are respectively shown in the attached image 3 and 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com