Method for preparing molybdenum disulfide nano-layered dispersion with high stability

A technology of molybdenum disulfide and nano-sheets, which can be applied in household utensils, inks, applications, etc., can solve the problems of poor stability of molybdenum disulfide two-dimensional nanomaterials, and achieve low cost, simple preparation process, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

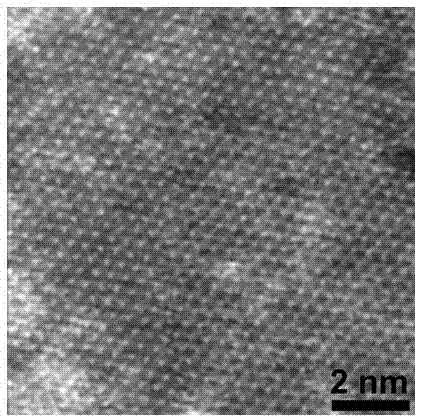

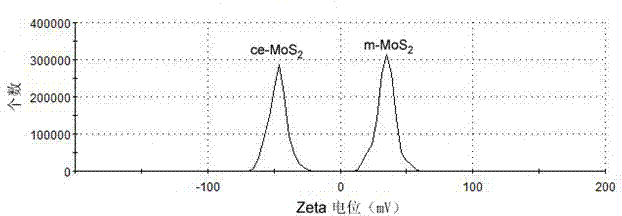

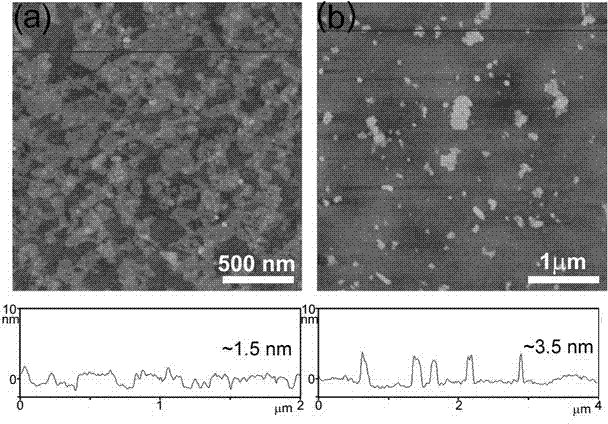

[0059] The molybdenum disulfide nanosheet dispersion prepared by the lithium ion intercalation method prepares the molybdenum disulfide nanosheet dispersion with high stability, and the preparation steps include:

[0060] 1) Add 0.3 g molybdenum disulfide crystals to 3 mL of 1.6 M n-butyllithium n-hexane solution in a nitrogen glove box, and stir to fully react at room temperature;

[0061] 2) filtering through a Buchner funnel, and then fully washing with n-hexane to obtain molybdenum disulfide powder intercalated with lithium ions;

[0062] 3) Disperse the lithium ion intercalated molybdenum disulfide powder prepared in step 2) in water to form a 10 mg / mL suspension, ultrasonically disperse for 2 hours, and fully dialyze the obtained solution with a dialysis bag with a molecular weight cut-off of 10,000;

[0063] 4) The unstripped molybdenum disulfide crystals are removed by centrifugation at 2000rpm, and then diluted with the solution to obtain a molybdenum disulfide nanosh...

Embodiment 2

[0067] The molybdenum disulfide nanosheet dispersion prepared by the lithium ion intercalation method prepares the molybdenum disulfide nanosheet dispersion with high stability, and the preparation steps include:

[0068] 1) Add 0.3 g molybdenum disulfide crystals to 3 mL of 1.6 M n-butyllithium n-hexane solution in a nitrogen glove box, and stir to fully react at room temperature;

[0069] 2) filtering through a Buchner funnel, and then fully washing with n-hexane to obtain molybdenum disulfide powder intercalated with lithium ions;

[0070] 3) Disperse the lithium ion intercalated molybdenum disulfide powder prepared in step 2) in water to form a 10 mg / mL suspension, ultrasonically disperse for 2 hours, and fully dialyze the obtained solution with a dialysis bag with a molecular weight cut-off of 10,000;

[0071] 4) The unstripped molybdenum disulfide crystals were removed by centrifugation at 2500 rpm, and then diluted with the solution to obtain a molybdenum disulfide nano...

Embodiment 3

[0075] The molybdenum disulfide nanosheet dispersion prepared by the lithium ion intercalation method prepares the molybdenum disulfide nanosheet dispersion with high stability, and the preparation steps include:

[0076] 1) Add 0.3 g molybdenum disulfide crystals to 3 mL of 1.6 M n-butyllithium n-hexane solution in a nitrogen glove box, and stir to fully react at room temperature;

[0077] 2) filtering through a Buchner funnel, and then fully washing with n-hexane to obtain molybdenum disulfide powder intercalated with lithium ions;

[0078] 3) Disperse the lithium ion intercalated molybdenum disulfide powder prepared in step 2) in water to form a 10 mg / mL suspension, ultrasonically disperse for 2 hours, and fully dialyze the obtained solution with a dialysis bag with a molecular weight cut-off of 10,000;

[0079] 4) The unstripped molybdenum disulfide crystals were removed by centrifugation at 3000 rpm, and then diluted with the solution to obtain a molybdenum disulfide nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com