Phase change micro-capsule for clothing thermoregulation as well as preparation method and application thereof

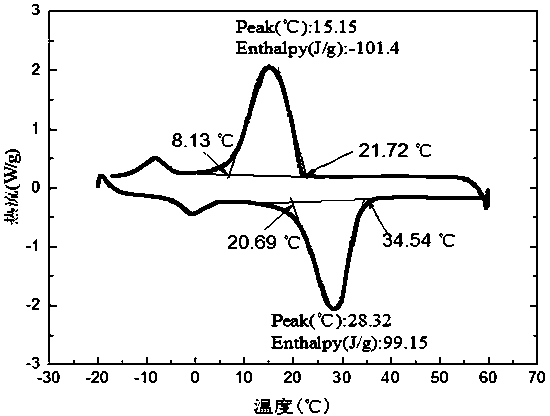

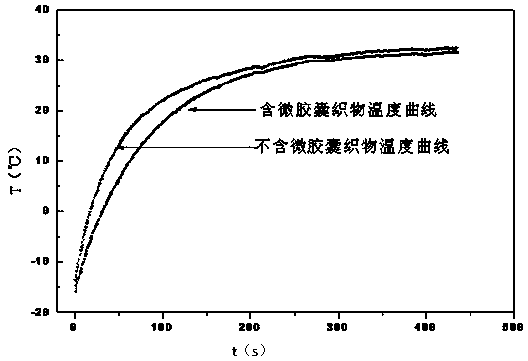

A phase change microcapsule and temperature regulation technology, which is applied in the field of clothing and textiles to achieve the effects of large heat storage, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

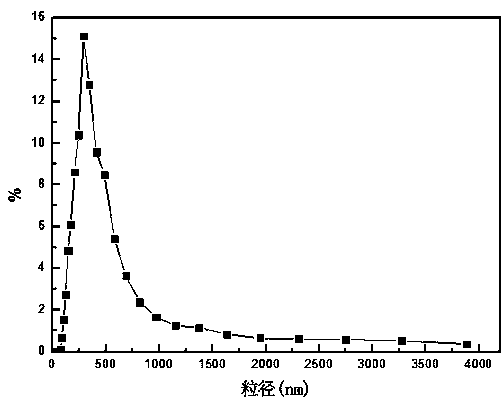

Embodiment 1

[0024] (1) Preparation of microcapsules: Weigh 4% OP-10 emulsifier and mix with the core material, wherein the core material is a mixture of n-octadecane and n-hexadecane with a mass ratio of 11.3:1, add deionized water Dissolve, transfer to a three-necked flask, stir at 2000r / min under nitrogen protection, and stir for 30min to form an O / W emulsion. Add freshly prepared ferrous sulfate (the amount is 1% of the mass of cetane), ammonium persulfate (the amount is 11% of the mass of hexadecane) and cross-linking agent diethanol dimethyl to the O / W type emulsion Acrylate (the amount is 1.16 times the mass of hexadecane), and methyl methacrylate (MMA) (the amount is 10.3 times the mass of hexadecane) is slowly added dropwise with a constant pressure funnel, and the dropping time is controlled for about 15 minutes (The total amount of dripping is 83% of hexadecane), and the dripping process always ensures stirring at a speed of 2000r / min. Then add the initiator azobisisobutylcyani...

Embodiment example 2

[0033] (1) Preparation of microcapsules: Weigh 9% OP-10 emulsifier and mix with the core material, wherein the core material is a mixture of n-octadecane and n-hexadecane with a mass ratio of 20:1, add deionized water Dissolve, transfer to a three-necked flask, stir at 2000r / min under nitrogen protection, and stir for 30min to form an O / W emulsion. Add freshly prepared ferrous sulfate (1.2% of cetane), ammonium persulfate (13% of cetane) and crosslinker diethanol dimethacrylic acid to the O / W emulsion ester (the dosage is 1.5 times that of hexadecane), and methyl methacrylate (MMA) (the dosage is 13 times that of hexadecane) is slowly added dropwise with a constant pressure funnel, and the dropping time is controlled for about 15 minutes. The process always ensures 2000r / min rotation speed stirring. Then add the initiator azobisisobutylcyanide (AIBN), Na 2 S 2 o 7 (The amount of AIBN is 46% of hexadecane, Na 2 S 2 o 7 The consumption is 13% of hexadecane), because MMA i...

Embodiment example 3

[0038] (1) Preparation of microcapsules: OP-10 emulsifier and core material with 4% core material mass, wherein the core material is a mixture of n-octadecane and n-hexadecane with a mass ratio of 5:1, dissolved in deionized water, Transfer to a three-necked flask, stir at a speed of 2000r / min under nitrogen protection, and stir for 30min to form an O / W emulsion. Add freshly prepared ferrous sulfate (2% of hexadecane), ammonium persulfate (10% of hexadecane) and crosslinker diethanol dimethacrylic acid to the O / W emulsion ester (the dosage is 1.3 times that of hexadecane), and methyl methacrylate (MMA) (the dosage is 14 times that of hexadecane) is slowly added dropwise with a constant pressure funnel, and the dropping time is controlled for about 15 minutes. The process always ensures 2000r / min rotation speed stirring. Then add the initiator azobisisobutylcyanide (AIBN), Na 2 S 2 o 7 (The amount of AIBN is 47% of hexadecane, Na 2 S 2 o 7 The consumption is 16% of hexad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Freezing temperature | aaaaa | aaaaa |

| Heat of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com