Method for preparing hollow spheres through microwave-assisted aerosol

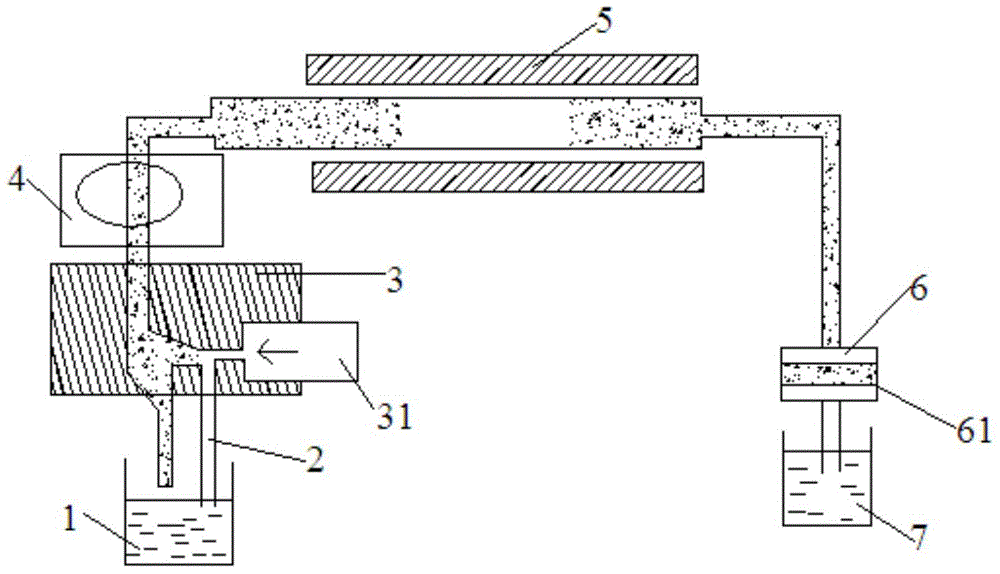

A microwave-assisted, hollow sphere technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of reduced specific surface area, small impurity content, and long aging time, and achieves low cost, short production cycle, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A. Weigh 3.0g of silica sol with a concentration of 40% and a particle size of 50nm, add 40.0g of pure water to dilute to a concentration of 2.8%, add 1.0g of ammonium bicarbonate, and mix well to obtain a precursor solution;

[0037] B. Put the above precursor solution into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 18psi, and make aerosol droplets through atomization;

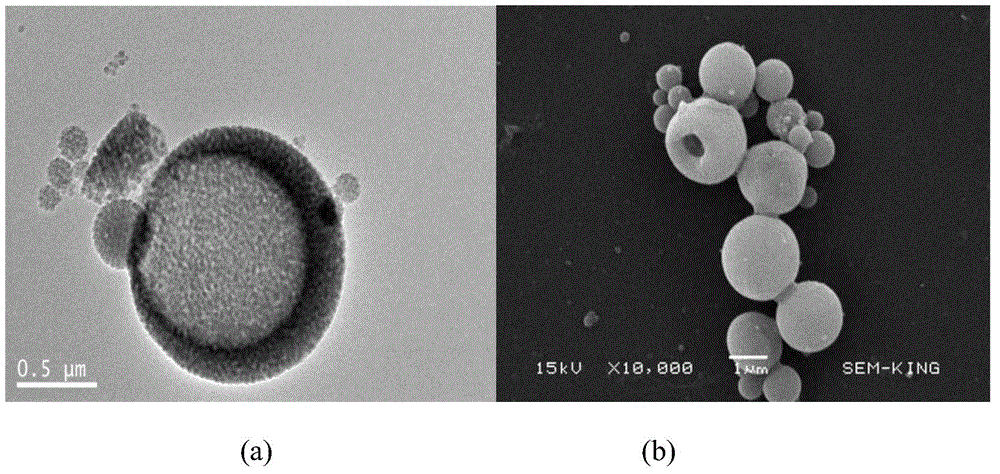

[0038] C. Introduce the aerosol droplets generated above into the microwave generator (microwave output power 700W, action time 17.5s), and then enter the tube furnace (set the temperature at 400°C) to dry for 5s, and the dried particles are passed through the filter The temperature of the filter is maintained at 80°C, and the collected product is a dry hollow spherical powder particle, and its particle size and shape are shown in the attached picture image 3 shown.

[0039] Depend on image 3 (a) It can be seen that after aerosol particl...

Embodiment 2

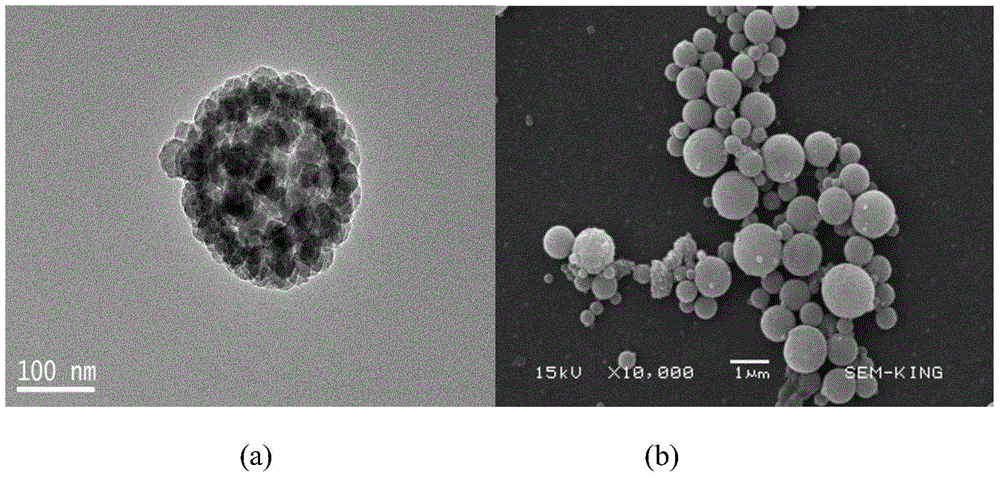

[0041] A. Weigh 5.0g of silica sol with a concentration of 30% and a particle size of 12nm, add 45.0g of pure water to dilute to a concentration of 3.0%, add 1.0g of ammonium bicarbonate, and mix well to obtain a precursor solution;

[0042] B. Put the above precursor solution into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 10psi, and make aerosol droplets through atomization;

[0043] C. Pass the aerosol droplets generated above through a microwave generator (microwave output power 350W, action time 25s), and then enter the tube furnace (set the temperature at 400°C) to dry for 5s, and the dried particles are on the filter For collection, the temperature of the filter is maintained at 80°C, and the collected product is dry hollow spherical powder particles.

Embodiment 3

[0045] A. Weigh 3.0g of silica sol with a concentration of 40% and a particle size of 22nm, add 40.0g of pure water to dilute to a concentration of 2.8%, add 0.8g of ammonium bicarbonate, and mix well to obtain a precursor solution;

[0046] B. Put the above precursor solution into the aerosol generator, open the nitrogen cylinder, adjust the spray pressure of the aerosol generator to 10psi, and make aerosol droplets through atomization;

[0047] C. Pass the aerosol droplets generated above through a microwave generator (microwave output power 700W, action time 25s), and then enter the tube furnace (set the temperature at 400°C) to dry for 5s, and the dried particles are on the filter For collection, the temperature of the filter is maintained at 80°C, and the collected product is dry hollow spherical powder particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com