Supported vanadyl pyrophosphate catalyst prepared by selective oxidation of n-butane and preparation method thereof

A vanadyl pyrophosphate catalyst and selective oxidation technology, which are applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex preparation method, long cycle, complex catalyst preparation process, etc. The effect of improving catalytic performance, high wear resistance and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

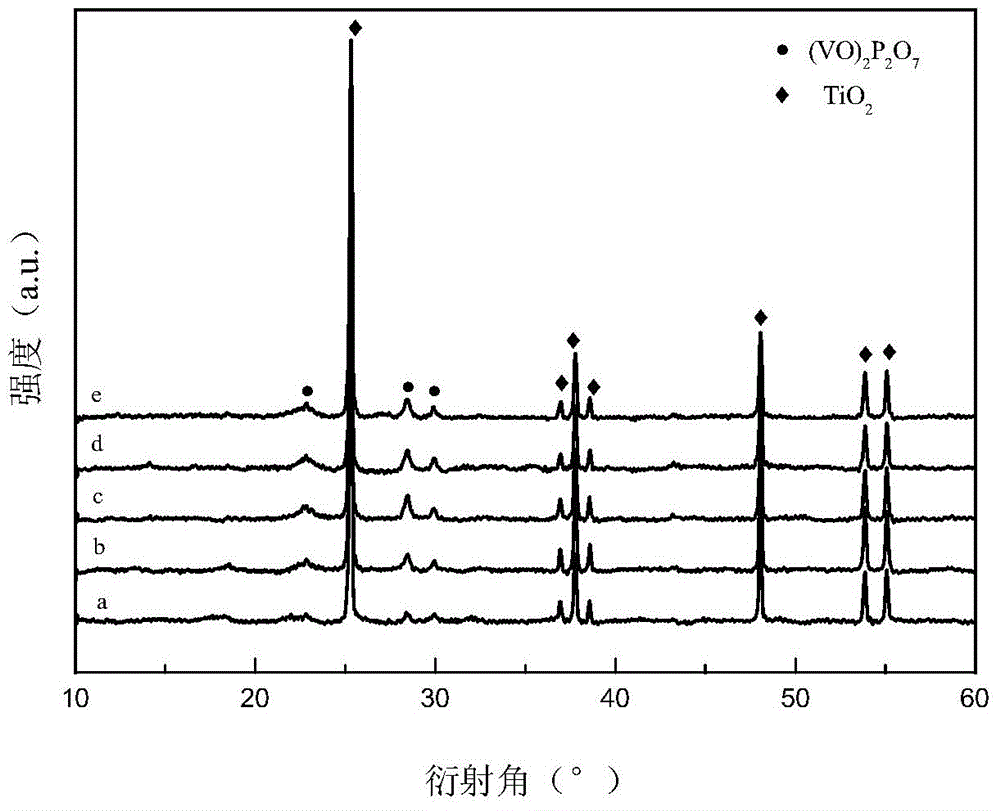

Image

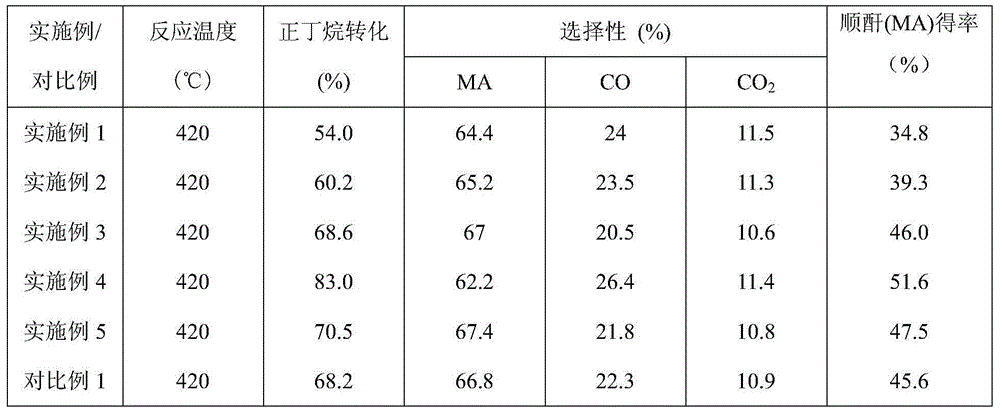

Examples

Embodiment 1

[0029] 1) Weigh 5g TiO 2 Immerse in 100ml of phosphoric acid solution with a concentration of 1.0mol / L, stir in an oil bath at 70°C for 12 hours, filter, wash with distilled water three times, and dry at 110°C as a spare carrier.

[0030] 2) Weigh 0.54g V 2 o 5 Mix in isobutanol-benzyl alcohol (12ml / 12ml) mixed solvent, heat and reflux at 140°C for 6h, when the mixture turns black, add 3g of the carrier TiO treated by step 1) 2 , continue to reflux for 30min, after cooling the above mixture, slowly add 0.82g of phosphoric acid with a concentration of 85% dropwise, then rapidly raise the temperature to 140°C, and continue to reflux for 6h to form a blue precipitate, which is filtered after cooling, and the obtained solid is successively washed with isobutyl Alcohol and acetone were washed twice respectively, and the filtrate was dried in an oven at 110° C. for 12 hours to obtain the precursor of the catalyst of the present invention. The catalyst precursor is pressed into ta...

Embodiment 2

[0034] 1) Same as step 1) in Example 1.

[0035] 2) Weigh 0.80g V 2 o 5 Mix in isobutanol-benzyl alcohol (17ml / 17ml) mixed solvent, heat and reflux at 140°C for 6h, at this time the mixture turns black, then add 3g of carrier TiO treated by step 1) 2 , continue to reflux for 30min, after cooling the above mixture, slowly add 1.22g of phosphoric acid with a concentration of 85% dropwise, then rapidly raise the temperature to 140°C, and continue to reflux for 6h to form a blue precipitate. Alcohol and acetone were washed twice respectively, and the filtrate was dried in an oven at 110° C. for 12 hours to obtain the precursor of the catalyst of the present invention. The catalyst precursor is pressed into tablets, crushed, sieved, and a 40-80 mesh sample is taken for roasting.

[0036] 3) Place the catalyst precursor sample prepared in step 2) in a fluidized system fixed-bed roaster for roasting, the roasting conditions are the same as in Example 1, and the mass percentage of ...

Embodiment 3

[0039] 1) Same as step 1) in Example 1.

[0040] 2) Weigh 1.07g V 2 o 5 Mix in isobutanol-benzyl alcohol (23ml / 23ml) mixed solvent, heat and reflux at 140°C for 6h, when the mixture turns black, add 3g of the carrier TiO treated in step 1) 2 , continue to reflux for 30min, after cooling the above mixture, slowly add 1.63g of phosphoric acid with a concentration of 85% dropwise, then rapidly raise the temperature to 140°C, and continue to reflux for 6h to form a blue precipitate. Alcohol and acetone were washed twice respectively, and the filtrate was dried in an oven at 110° C. for 12 hours to obtain the precursor of the catalyst of the present invention. The catalyst precursor is pressed into tablets, crushed, sieved, and a 40-80 mesh sample is taken for roasting.

[0041] 3) Place the catalyst precursor sample prepared in step 2) in a fluidized system fixed-bed roaster for roasting, the roasting conditions are the same as in Example 1, and the mass percentage of each comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com