Treatment method of fluoride-containing wastewater

A treatment method and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of incomplete precipitation of fluoride ions, inability to meet industrial needs, and inability to recover hydrogen fluoride and other problems, to achieve the effect of high recovery rate, simple operation and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

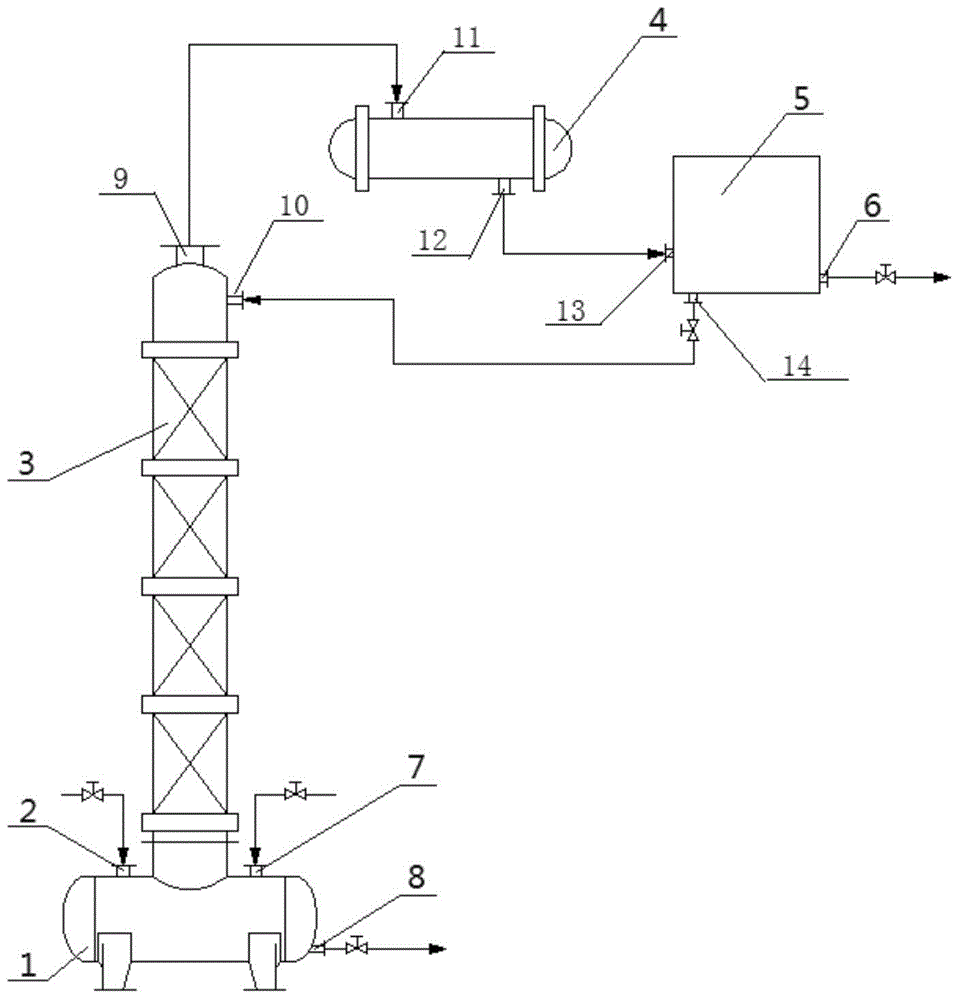

[0018] refer to figure 1 , the present invention utilizes the wastewater treatment rectification system to treat fluorine-containing wastewater by means of batch rectification; the wastewater treatment rectification system includes a rectification kettle 1, a packed rectification tower 3, a condenser 4 and a liquid reservoir 5. The rectification kettle 1 is provided with a waste liquid inlet 2, a solvent inlet 7 and a waste liquid outlet 8, and the top of the packed rectification tower 3 is provided with a gas outlet 9 and a reflux liquid inlet 10, and the inside of the packed rectification tower is Φ3×3mm Graphite Raschig rings are used as fillers, and the condenser 4 is provided with an air inlet 11 and a condensate outlet 12, and the liquid reservoir 4 is provided with a liquid inlet 13, a liquid outlet 6 and a reflux outlet 14; The top of the still still communicates with the bottom of the packed rectifying tower, the gas outlet 9 of the packed rectifying tower communicate...

Embodiment 2

[0021] 50g containing 30wt% trifluoroacetic acid, industrial waste water of 10wt% hydrogen fluoride is added in the rectification still from the waste liquid inlet of rectification still, add the water-absorbing solvent 200g that reuses is collected at the waste liquid outlet in embodiment 1 again from solvent inlet and SO 3 140g (recycled water-absorbing solvent and SO 3 , mixed well before adding to the tower kettle), stirred at 25°C and 0.110MPa for 30min until the water was completely absorbed, opened the condenser and heated the rectification kettle to 70°C and pressure of 0.110MPa under the condition of total reflux , continuously adjust the reflux ratio to control the top temperature of the packed rectification tower at 19-23°C and the pressure at 0.100MPa, and collect hydrogen fluoride from the gas outlet, and stop collecting when the top temperature of the packed rectification tower is higher than 23°C. Then gradually increase the heat load of the rectification kettl...

Embodiment 3

[0023]Equipment and operation are the same as embodiment 1. 50g of industrial wastewater containing 32wt% trifluoroacetic acid and 12wt% hydrogen fluoride was added to the rectifying still. Add 460g containing 30wt%SO 3 oleum, stirred and reacted at 20°C and 0.110MPa for 50min until the water was completely absorbed. Open the condenser and heat the rectification tank under the condition of total reflux. The temperature of the rectification tank is 75°C and the pressure of the tank is 0.110MPa. Stop collecting when the temperature at the top of the distillation tower is higher than 23°C. Gradually increase the heat load of the rectification column to 115°C and 0.115MPa, adjust the reflux ratio to control the top temperature of the packed rectification tower at 72-73°C, and the pressure to 0.100MPa, collect trifluoroacetic acid from the gas outlet, and use it as the packing rectification Stop collecting when the temperature at the top of the tower is higher than 73°C. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com