Organic fertilizer prepared from recovered wastes of pig farm and preparation method thereof

A technology of waste recycling and organic fertilizer, applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment, etc., can solve the problems of pollution, odor that cannot be removed, and poor fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

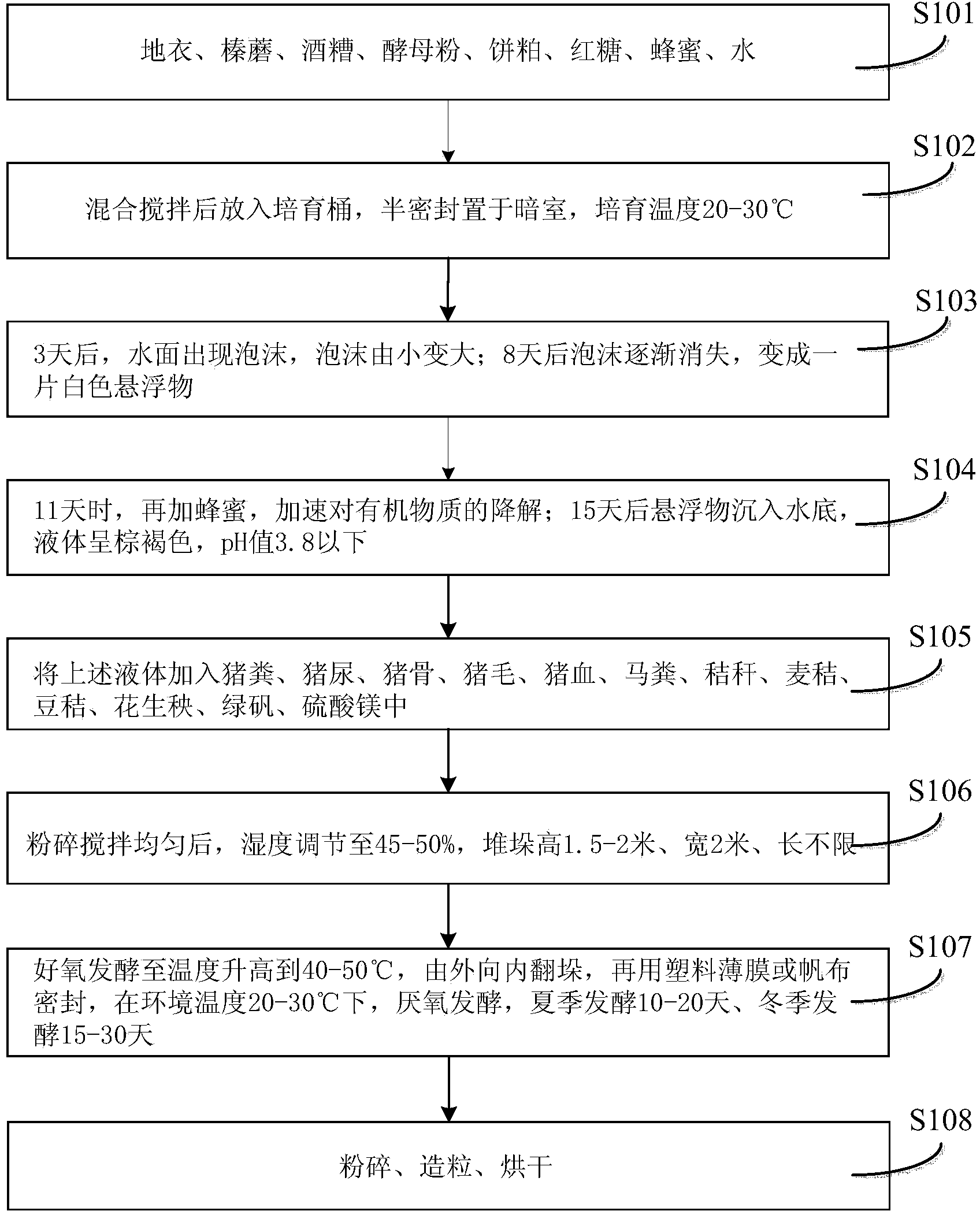

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides an organic fertilizer made by recycling pig farm waste, which is composed of the following raw materials by weight: 15 parts of lichen, 20 parts of hazel mushrooms, 24 parts of distiller's grains, 10 parts of yeast powder, 20 parts of cakes, 100 brown sugar, 50 honey, 300 pig manure, 10 pig urine, 5 pig bones, 1 pig hair, 7 pig blood, 20 horse manure, 70 straw, 10 wheat straw, 5 soybean straw , 5 parts of peanut seedlings, 6 parts of green alum, 1 part of magnesium sulfate.

[0024] The effects of selecting the above-mentioned raw materials are as follows:

[0025] Lichens: photosynthetic bacteria, which have the ability to decompose organic matter, convert harmful substances into harmless substances, and produce antioxidant substances during the conversion process, use sunlight and heat for photosynthesis to produce oxygen for other organisms to use, use CO 2 And nitrogen and other substances to synthesize carbohydrates, amino acids, vitamins ...

Embodiment 2

[0045] This embodiment provides an organic fertilizer made by recycling pig farm waste, which is composed of the following raw materials by weight: 20 parts of lichen, 28 parts of hazel mushrooms, 36 parts of distiller's grains, 15 parts of yeast powder, 25 parts of cake meal, 130 parts of brown sugar, 65 parts of honey, 380 parts of pig manure, 12 parts of pig urine, 6 parts of pig bones, 2 parts of pig hair, 10 parts of pig blood, 22 parts of horse manure, 80 parts of straw, 15 parts of wheat straw, 8 parts of soybean straw , 8 parts of peanut seedlings, 6.5 parts of green alum, and 1 part of magnesium sulfate.

[0046] The preparation method of the organic fertilizer obtained by recycling pig farm waste provided in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0048] This embodiment provides an organic fertilizer made by recycling pig farm waste, which is composed of the following raw materials by weight: 25 parts of lichen, 32 parts of hazel mushroom, 40 parts of distiller's grains, 18 parts of yeast powder, 28 parts of cake meal, 150 parts of brown sugar, 75 parts of honey, 400 parts of pig manure, 15 parts of pig urine, 8 parts of pig bones, 3 parts of pig hair, 12 parts of pig blood, 25 parts of horse manure, 90 parts of straw, 15 parts of wheat straw, 10 parts of soybean straw , 10 parts of peanut seedlings, 7 parts of green alum, and 1 part of magnesium sulfate.

[0049] The preparation method of the organic fertilizer obtained by recycling pig farm waste provided in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com