Bone graft material with plasticity and capability of enhancing and accelerating bone formation and preparation method thereof

A bone transplantation and plasticity technology, applied in medical science, prosthesis, etc., can solve the problems of further improvement of osteogenic ability, time-consuming and laborious, powder migration, etc., to achieve wide clinical application prospects, reduce patient pain, and accelerate bone. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of Plastic Bone Graft Material

[0035] (1) Preparation of decalcified bone matrix (DBM) powder

[0036] Wash the long bone of the donor, remove the periosteum, muscle, connecting tissue and cartilage, wash it with distilled water, cut it into small pieces of bone, freeze-dry it and crush it into a powder with a particle size of 500-1500 μm in liquid nitrogen. The obtained powder was degreased with chloroform for 12 hours, then decalcified with hydrochloric acid with a concentration of 0.5 mol / L for 4 hours, and the decalcified powder was washed with distilled water until the eluate was neutral. After the cleaned powder is freeze-dried, dehydrated, and gamma-ray sterilized, the DBM powder is obtained. The scanning electron microscope (SEM) picture is as follows: figure 1 shown.

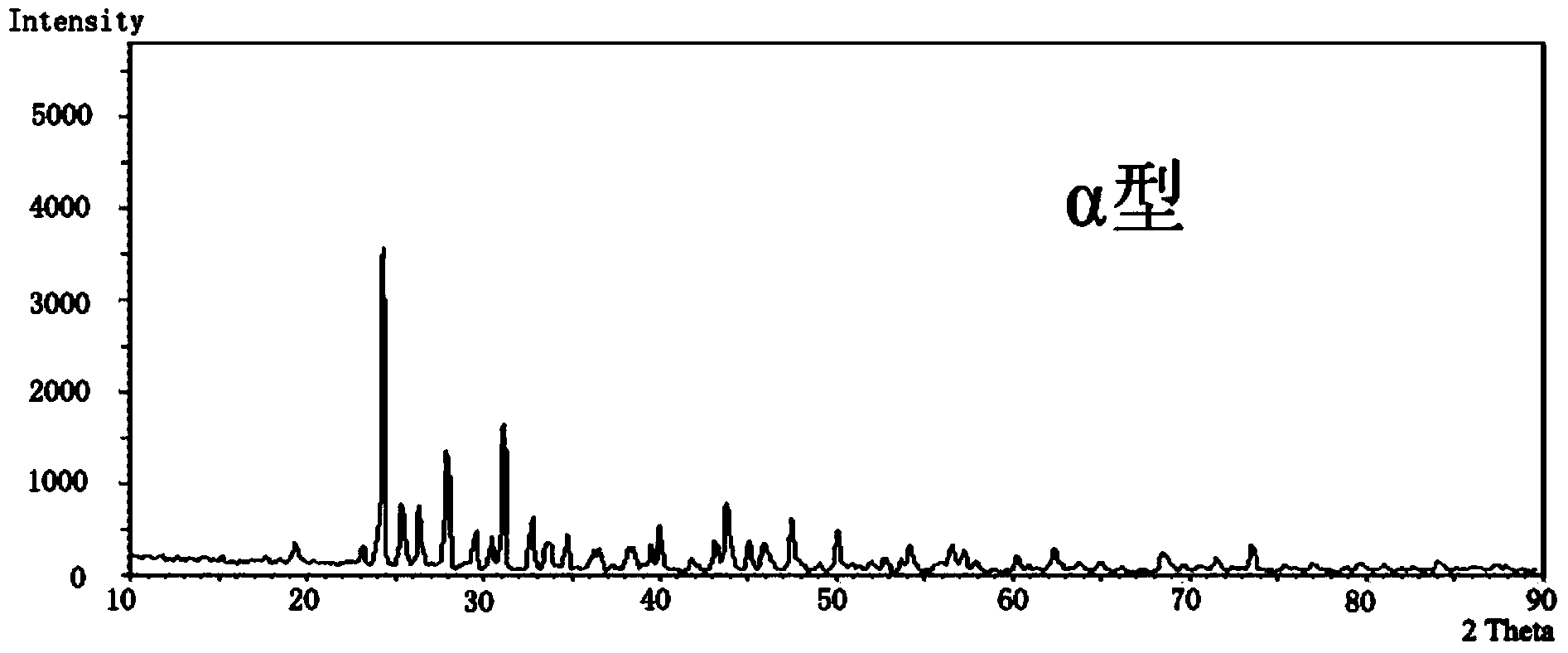

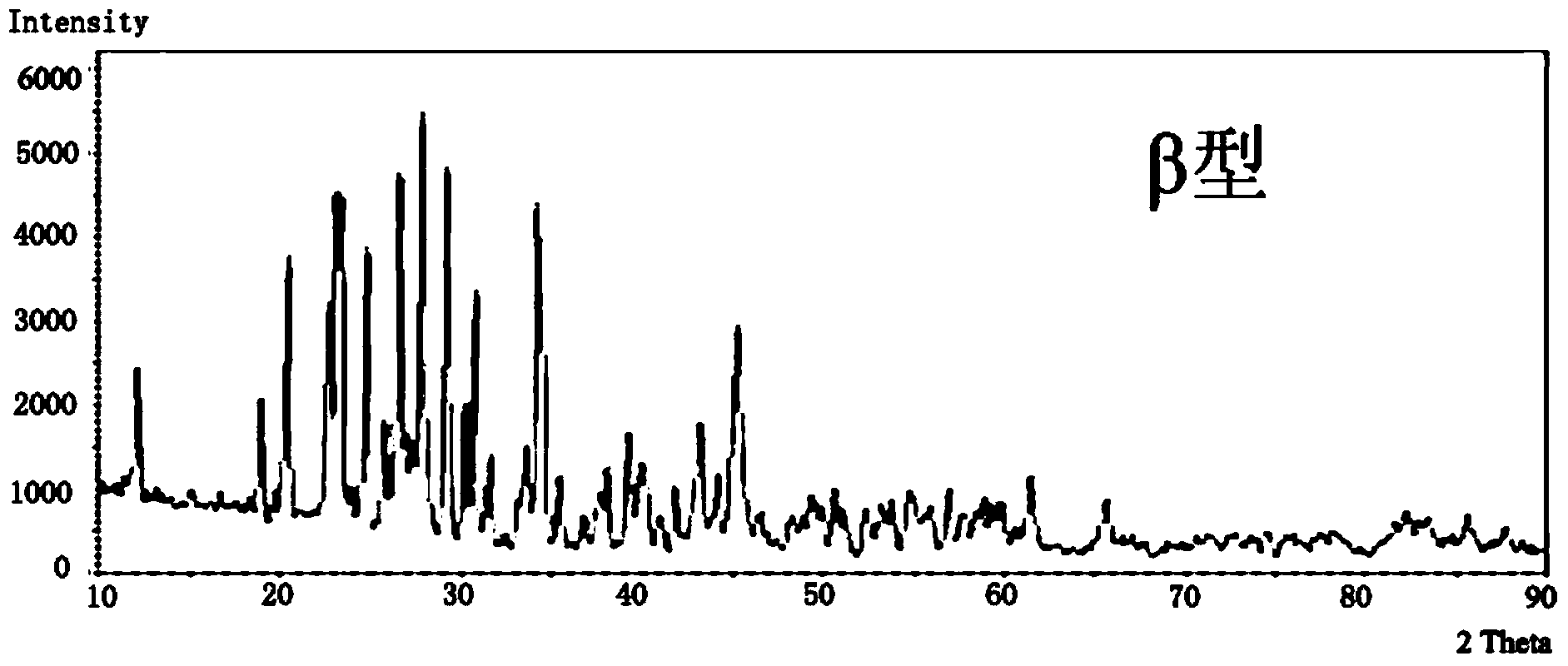

[0037] (2) Preparation of calcium strontium polyphosphate powder

[0038] Weigh strontium carbonate and calcium carbonate according to the molar content of strontium i...

Embodiment 2

[0043] Example 2: Preparation of Plastic Bone Graft Material

[0044] (1) Preparation of decalcified bone matrix (DBM) powder

[0045] Wash the long bone of the donor, remove the periosteum, muscle, connective tissue and cartilage, wash it with distilled water, cut it into small pieces of bone, freeze-dry it and crush it into a powder with a particle size of 500-1000 μm in liquid nitrogen. The obtained powder was degreased with ether for 18 hours, and then decalcified with 1 mol / L acetic acid for 24 hours, and the decalcified powder was washed with distilled water until the eluate was neutral. DBM powder is obtained after the cleaned powder is freeze-dried, dehydrated, gamma-ray sterilized and sterilized.

[0046] (2) Preparation of calcium strontium polyphosphate powder

[0047] Weigh strontium carbonate and calcium carbonate according to the molar content of strontium ions accounting for 45% of the total molar weight of strontium ions and calcium ions, mix the strontium ca...

Embodiment 3

[0052] Example 3: Preparation of Plastic Bone Graft Material

[0053] (1) Preparation of decalcified bone matrix (DBM) powder

[0054] Wash the long bone of the donor, remove the periosteum, muscle, connecting tissue and cartilage, wash it with distilled water, cut it into small pieces of bone, freeze-dry it and crush it into a powder with a particle size of 1000-1500 μm in liquid nitrogen. The obtained powder was degreased with acetone for 24 hours, then decalcified with formic acid with a concentration of 1 mol / L for 24 hours, and the decalcified powder was washed with distilled water until the eluate was neutral. DBM powder is obtained after the cleaned powder is freeze-dried, dehydrated, gamma-ray sterilized and sterilized.

[0055] (2) Preparation of calcium strontium polyphosphate powder

[0056] Weigh strontium dihydrogen phosphate and calcium dihydrogen phosphate according to the molar content of strontium ions accounting for 35% of the total molar weight of strontiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com