Preparation method of adsorbent for removing indoor low-concentration hydrogen sulfide

A low-concentration, hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, alkali metal oxides/hydroxides, etc., can solve the problem that the desorption effect is not very obvious, the adsorption effect changes, and cannot be eliminated well Harmful gases and other problems, to achieve good chemical adsorption effect, increased adsorption effect, and obvious effect of material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of modified 5A molecular sieve loaded zinc oxide chemical adsorbent comprises the following steps:

[0021] (1) 5A molecular sieve activation treatment: Grind 5A molecular sieve to powder at 25°C, add it to hydrochloric acid solution, and soak for 3 hours with magnetic stirring, then add Na 2 CO 3 The solution makes the mixture neutral.

[0022] More specifically, the activation method includes the following steps: grind 5A molecular sieve (spherical) to powder at room temperature, add it to 2mol / L hydrochloric acid, and mix and stir for 3 hours for activation treatment. 1mol / L Na 2 CO 3 The solution was added to a hydrochloric acid solution containing molecular sieves to neutralize. Then put it into a blast drying oven and dry at 105°C for 24 hours to obtain a dry product, grind it to a powder state and sieve it with a 200-mesh standard sieve to obtain a powder, which is ready for use.

[0023] (2) Modification of 5A molecular sieve: Weigh 2...

Embodiment 1

[0027] Grind the 5A molecular sieve (spherical) to powder at 25°C, add it into 2mol / L hydrochloric acid, and stir with magnetic force for 3h for activation. After adding Na 2 CO 3 solution to neutralize. Then the sample was put into a blast drying oven at 105°C for 12 hours to obtain a dry product, which was ground to a powder and sieved with a 200-mesh standard sieve to obtain a powder for use.

[0028] Preparation of the modified 5A molecular sieve carrier: Weigh 27g of ammonia water and add it to 300-400ml of deionized water, and stir at a constant temperature of 23-27°C for 15min. After that, 5-10 g of CTMAB was weighed and slowly added to the solution, and the stirring was continued for 15 min. Then, the dried 5A molecular sieve (8-12g) was slowly added to the mixture, and kept stirring at constant temperature for 15 minutes. Make the molecular sieve mix well. Weigh 30g of TEOS and add it dropwise to the stirred mixture (20-30min). Then stir at constant temperature ...

Embodiment 2

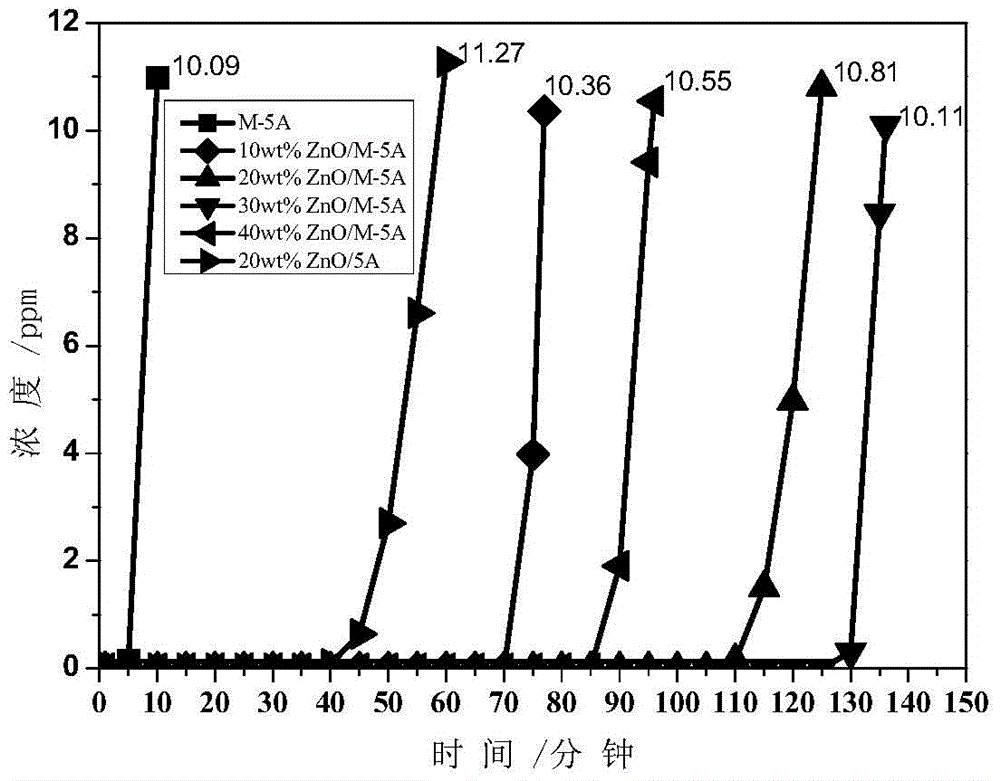

[0030] The 5A molecular sieve carrier was prepared as described in Example 1. Zinc nitrate was loaded on the prepared carrier according to ZnO10wt%. The modified 5A molecular sieve chemical adsorbent loaded with 10wt% ZnO was obtained by roasting in a muffle furnace (the roasting temperature was 400-450°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com