A high specific energy direct methanol fuel cell membrane electrode and its preparation method

A methanol fuel cell and membrane electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve problems such as increasing cathode polarization, reducing DMFC specific energy, and fuel waste system efficiency, so as to avoid contact resistance and reduce Volume, to avoid the effect of increasing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

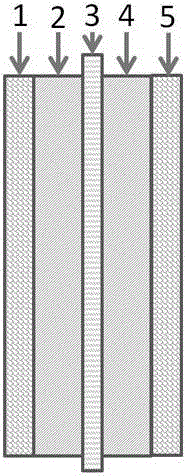

[0023] Specific implementation mode one: combine figure 1 The present embodiment will be described. The direct methanol fuel cell membrane electrode of this embodiment is composed of an anode diffusion layer 1 , an anode catalyst layer 2 , a proton exchange membrane 3 , a cathode catalyst layer 4 , and a cathode diffusion layer 5 . Wherein the anode diffusion layer 1 and the cathode diffusion layer 5 are both made of graphene airgel / stainless steel felt composite material. The anode catalytic layer 2 is located on the left side of the proton exchange membrane 3, the anode diffusion layer 1 is located on the left side of the anode catalytic layer 2; the right side of the proton exchange membrane 3 is the cathode catalytic layer 4 and the cathode diffusion layer 5 in turn.

[0024] In this embodiment, the preparation of the graphene airgel / stainless steel felt composite material can adopt the following two methods:

[0025] Method 1: Ultrasonic cleaning of stainless steel felt...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment provides a method for preparing a direct methanol fuel cell membrane electrode, the steps of which are as follows:

[0028] Step 1, preparation of graphene airgel / stainless steel felt composite material:

[0029] Clean the stainless steel felt with a thickness of 0.5μm and a size of 12*25mm ultrasonically for 20 minutes with anhydrous ethanol solution, ultrasonically clean with ultrapure water for 5 minutes, soak in 1M hydrochloric acid solution for 10 minutes, put in 5ml / L oxidation The graphene aqueous solution was ultrasonically oscillated for 60 minutes, placed in a vacuum drying oven at 60°C for 15 hours, taken out and then frozen with liquid nitrogen, transferred to a freeze dryer for 30 hours of freeze-drying, and finally dried in nitrogen at 450°C The graphene airgel / stainless steel felt composite material can be obtained by carrying out sintering treatment for 3 hours under protection.

[0030] Step 2, preparation of the anode gas...

specific Embodiment approach 3

[0036] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the preparation method of the graphene airgel / stainless steel felt composite material in the step one is: the thickness is 0.5 μm, the size is 12*25mm The stainless steel felt was ultrasonically cleaned with anhydrous ethanol solution for 15 minutes, ultrasonically cleaned with ultrapure water for 10 minutes, soaked in 1.5M hydrochloric acid solution for 15 minutes, placed in 10ml / L graphene oxide aqueous solution and ultrasonically oscillated for 40 minutes, taken out and placed Put it into vitamin C solution with a concentration of 10g / L, reduce it at 60°C for 3 hours, wash it with ultrapure water 4 times after cooling, and transfer it to a freeze dryer for 20 hours of freeze-drying to obtain graphene gas condensation Glue / stainless steel felt composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com