Method for preparing high-flatness tungsten-nickel-iron alloy plate

A tungsten-nickel-iron alloy and flatness technology, which is applied in the field of preparing high-flatness tungsten-nickel-iron alloy plates, can solve problems affecting the flatness of finished products, total deformation limit, long production cycle, etc., and achieve low equipment loss and reduced difference between the same plates Effect of small size and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

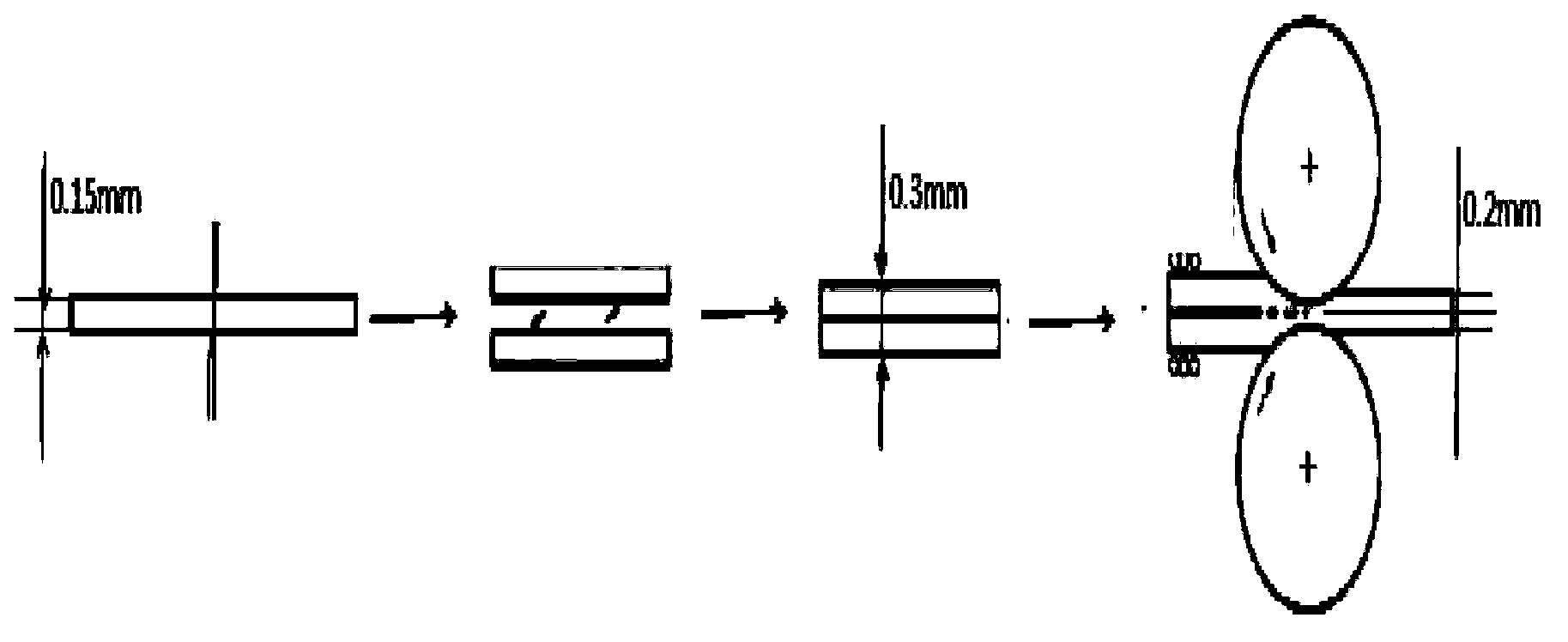

Image

Examples

Embodiment 1

[0048] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 40KN, and the rolling speed is controlled at 2.5cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.8mm .

[0049] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a sintered tungsten-nickel-iron alloy thin plate. The sintering temperature is 1300 ° C and the sintering time is 3 hours.

[0050] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0051] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1300°C, and the refiring time is 3 hours.

[0052] Repeat the first two steps until the th...

Embodiment 2

[0055] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 60KN, and the rolling speed is controlled at 2.0cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.6mm .

[0056] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a tungsten-nickel-iron alloy thin plate sintered body. The sintering temperature is 1300 ° C and the sintering time is 2.5 hours.

[0057] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0058] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1250°C, and the refiring time is 2.5 hours.

[0059] Repeat the first two steps unt...

Embodiment 3

[0062] The tungsten-nickel-iron alloy powder after granulation and drying is rolled into a billet, the rolling pressure is controlled at 80KN, and the rolling speed is controlled at 1.5cm / s, and the tungsten-nickel-iron alloy powder is rolled into a thin plate green body with a thickness of 1.2mm .

[0063] The prepared tungsten-nickel-iron alloy thin plate green body is placed in a sintering furnace, and sintered under the protection of hydrogen to obtain a sintered tungsten-nickel-iron alloy thin plate. The sintering temperature is 1250 ° C and the sintering time is 2.5 hours.

[0064] The sintered body is cold-rolled and rolled, and cold-rolled for several passes until the total deformation of the thin plate reaches 40%.

[0065] Place the cold-rolled tungsten-nickel-iron alloy sheet in a sintering furnace for refiring, the protective atmosphere is hydrogen, the refiring temperature is 1250°C, and the refiring time is 2 hours.

[0066] Repeat the first two steps until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com