Molecular sieve nanotube aerogel and preparation method thereof

A molecular sieve and airgel technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long molecular diffusion path, uncontrollable mesopore and macropore diameter, and numerous steps , to achieve the effect of shortening the molecular diffusion path, facilitating the catalysis of macromolecules, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Preparation of Silicalite-1 molecular sieve nanotube airgel

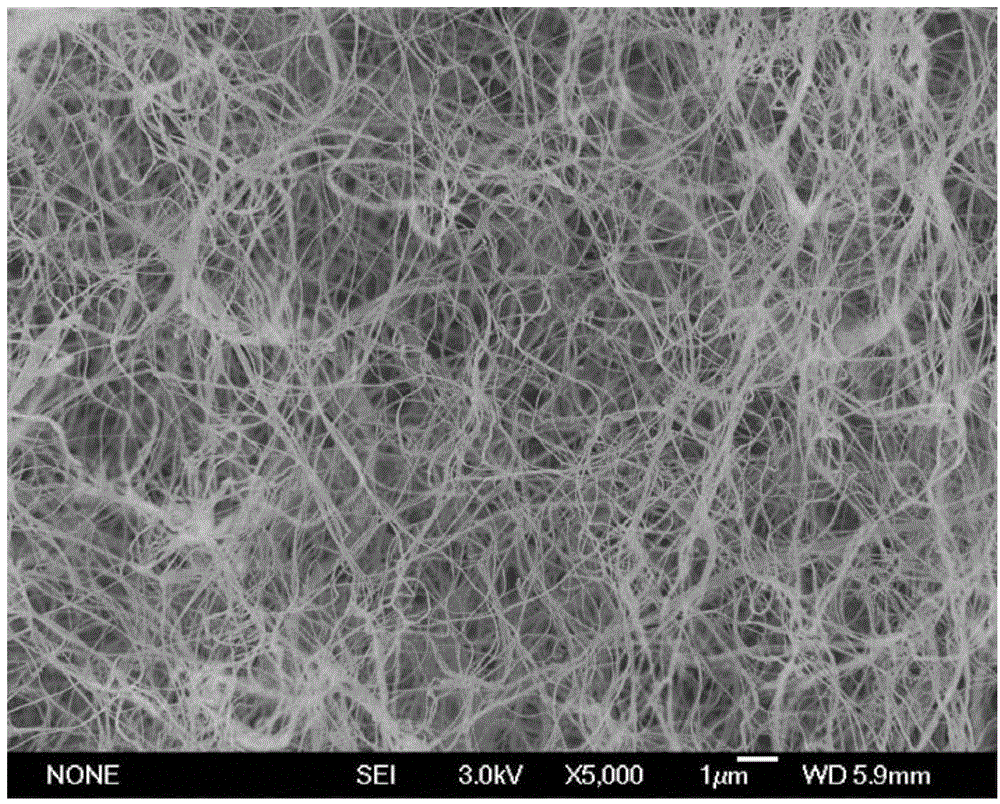

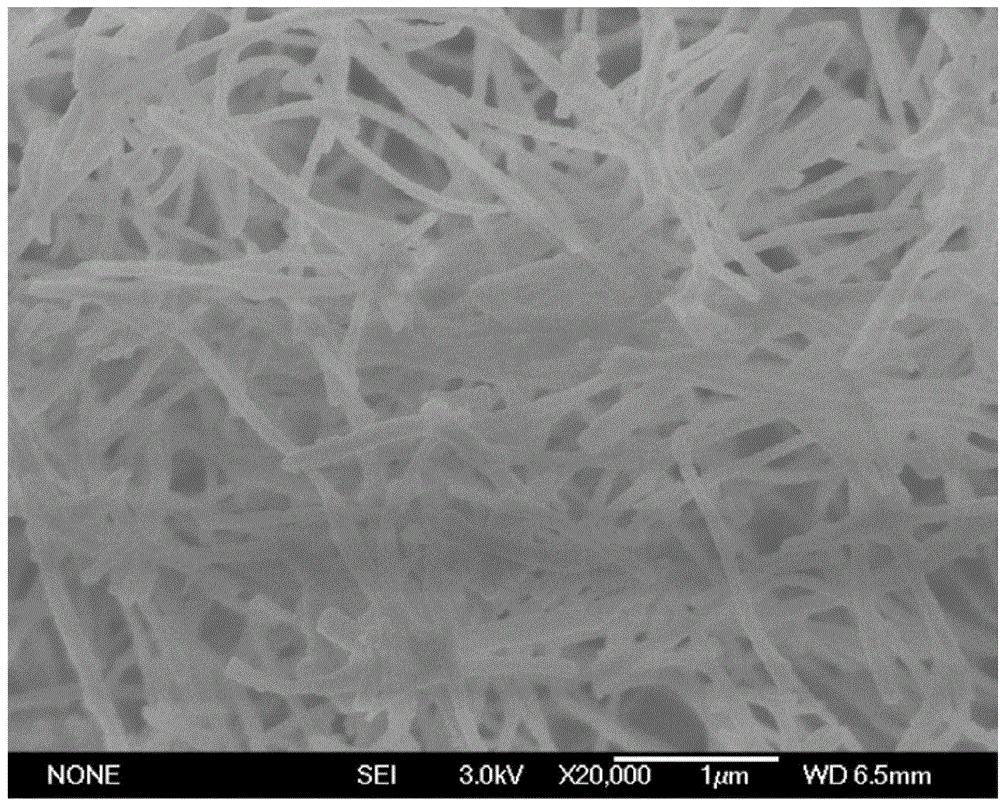

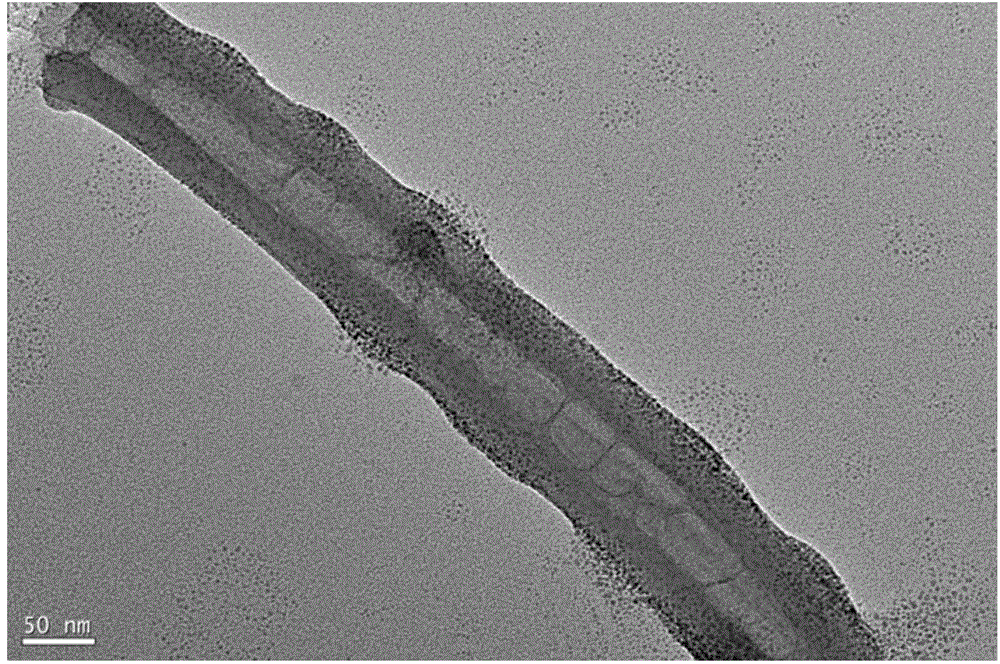

[0067] (1) Preparation of precursor: Add 0.01g of cetylmethylammonium bromide (CTAB) to 10ml of ethanol solution, stir to dissolve at room temperature, add 1ml of tetraethyl orthosilicate and stir to dissolve, then add cellulose Airgel 0.01g, stir at room temperature to make the airgel fully swell and become translucent, add 1ml of ammonia water, stir at room temperature for 2 hours, at this time the soft translucent massive airgel turns into hard and slightly elastic white gas Gel blocks. After being taken out by filtration, it was washed three times with ethanol and dried in an oven at 30°C. Scanning electron microscope image of nanocellulose airgel figure 1 As shown, the cellulose filaments with a diameter of about 20 nm are cross-linked to form a network-like structure. The scanning electron microscope image of the precursor is shown in figure 2 As shown, amorphous silicon dioxide is evenl...

Embodiment 2

[0071] Example 2: Preparation of Silicalite-1 molecular sieve nanotube airgel

[0072] (1) Preparation of precursor: Add 0.2g CTAB to 10ml tert-butanol solution, stir to dissolve with slight heat, add 2.5ml of ammonia water and stir to dissolve, add 0.03g of cellulose airgel, stir at room temperature to make the air coagulate The gel is fully swollen and becomes translucent. Add 5ml of tetraethyl orthosilicate and stir at room temperature for 6 hours. At this time, the soft and translucent block-shaped airgel becomes a hard and slightly elastic white airgel block. After being taken out by filtration, it was washed five times with ethanol, and dried in an oven at 100°C. The scanning electron microscope of the precursor as Figure 10 As shown, the amorphous silica is evenly coated on the outer layer of the cross-linked cellulose filaments to form nanotubes with a wall thickness of about 80 nm, and the nanotubes are cross-linked to form a network skeleton.

[0073] (2) Preparat...

Embodiment 3

[0076] Embodiment 3: Preparation of Silicalite-1 molecular sieve nanotube airgel

[0077] (1) Preparation of precursor: Add 1g CTAB to 10ml ethanol solution, stir to dissolve with slight heat, add 7ml of propyl orthosilicate and stir to dissolve, add 0.05g of cellulose airgel, stir at room temperature to make the air coagulate The glue is fully swollen and becomes translucent. Add 5ml of ammonia water and stir at room temperature for 24 hours. The subsequent operation steps are the same as in Example 2 (1).

[0078] (2) Preparation of Silicalite-1 seed liquid: Add 16g of ethyl orthosilicate to 27ml of tetrapropylammonium hydroxide solution, stir at room temperature for 24h, then put the above mixed solution into a flask, and reflux at 90°C After heating for 96 hours, the obtained seed crystal solution was ultracentrifuged at 12000 rpm for 20 minutes, the supernatant liquid was discarded to take the lower solid seed crystal, and then dispersed into distilled water to form a col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com