Manganese slag-based concrete admixture function regulator and preparation method thereof

A conditioner and concrete technology, which is applied in the field of manganese slag-based concrete admixture function regulator and its preparation, can solve the problems of manganese slag tailings dam covering a large area, unfavorable surrounding environment, and environmental hazards, and achieve guaranteed strength , solve environmental pollution, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

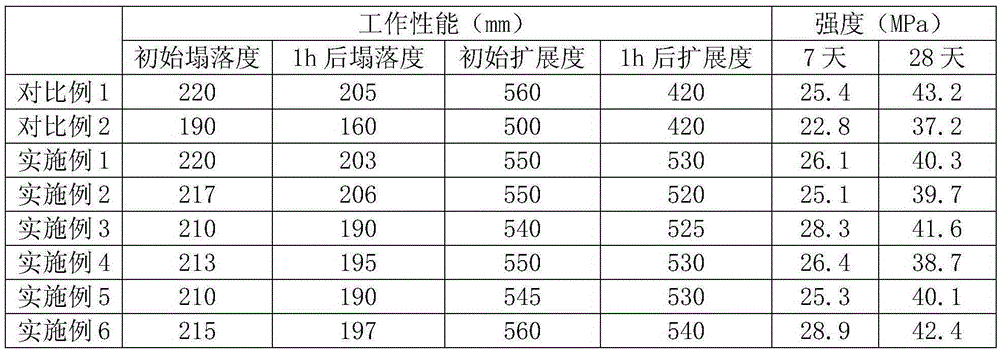

Examples

Embodiment 1

[0035] Mix 420g of polyether polycarboxylate high-efficiency water reducer with a solid content of 40%, 420g of polyester polycarboxylate high-efficiency water reducer, and compound active activator 100g and stir for 10min, then add retarder sodium gluconate 20g, compound Stir 20g of air-entraining agent for 5 minutes to obtain the function regulator of manganese slag-based concrete admixture;

[0036] Wherein the composite activity stimulating agent is hydrazine hydrate, N, N-bis(2-hydroxyethyl) ethylenediamine, N, N'-bis(2-hydroxypropyl) diethyltriamine, sodium sulfate in a weight ratio of 4 :4:2:2 for composite;

[0037] The composite air-entraining agent is prepared by compounding the mass ratio of triterpene saponin: fatty alcohol polyoxyethylene sodium sulfonate = 1:1.

[0038] Manganese slag-based admixtures are used to replace slag and fly ash in equal amounts to prepare concrete. The concrete ratio is cement: manganese slag-based admixtures: river sand: machine-made ...

Embodiment 2

[0040] Mix 420g of polyether polycarboxylate high-efficiency superplasticizer with a solid content of 40%, 420g of polyester-type polycarboxylate high-efficiency water reducer, and compound active activator 120g and stir for 10min, then add retarder sodium gluconate 20g, compound Stir 20g of air-entraining agent for 5 minutes to obtain the function regulator of manganese slag-based concrete admixture;

[0041] Wherein the composite activity stimulating agent is hydrazine hydrate, N, N-bis(2-hydroxyethyl) ethylenediamine, N, N'-bis(2-hydroxypropyl) diethyltriamine, sodium sulfate in a weight ratio of 6 :2:1:1 for composite;

[0042] The composite air-entraining agent is prepared by compounding the mass ratio of triterpene saponin: fatty alcohol polyoxyethylene sodium sulfonate = 1:1.

[0043] Manganese slag-based admixtures are used to replace slag and fly ash in equal amounts to prepare concrete. The concrete ratio is cement: manganese slag-based admixtures: river sand: machi...

Embodiment 3

[0045] Stir 280g of polyether polycarboxylate superplasticizer with a solid content of 40%, 560g of polyester polycarboxylate superplasticizer, and 120g of compound active activator for 10min, then add retarder lignosulfonate 20g , Composite air-entraining agent 20g and stirring for 5 minutes, the manganese slag-based concrete admixture function regulator can be obtained,

[0046] Wherein the composite activity stimulating agent is hydrazine hydrate, N, N-bis(2-hydroxyethyl) ethylenediamine, N, N'-bis(2-hydroxypropyl) diethyltriamine, sodium sulfate in a weight ratio of 5 :3:1:1 for composite;

[0047] The composite air-entraining agent is prepared by compounding the mass ratio of triterpene saponin: fatty alcohol polyoxyethylene sodium sulfonate = 1:1.

[0048] Manganese slag-based admixtures are used to replace slag and fly ash in equal amounts to prepare concrete. The concrete ratio is cement: manganese slag-based admixtures: river sand: machine-made sand: gravel: water = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com