A kind of preparation method of unsaturated polyester flame retardant composite material

A flame-retardant composite material and unsaturated technology, which is applied in the field of polymer material preparation, can solve problems such as low flame-retardant efficiency, threats to the environment and personal life safety, and reduced UV resistance of matrix materials, so as to prevent further escape, Effect of increasing high temperature stability and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Under the protection of nitrogen, add 0.125mol PEPA, 0.1mol triethylamine, 100ml acetonitrile into the reaction flask equipped with magnetic stirring, reflux condensing device and drying protection device. The buret starts to add 0.05mol methyl vinyl dichlorosilane dropwise, and the dropwise addition is complete within 1-2 hours. Then the temperature was raised to 60°C for 2h, and then raised to reflux temperature for 6h, the reaction was stopped and cooled to room temperature. Filter, wash with ether and methanol, and dry for 8 hours at 80°C under a vacuum of 0.1 MPa to obtain the target flame retardant DPMVSi.

[0029] Add 90g of 191 to a 250ml beaker at room temperature #Pure unsaturated polyester and 10g target flame retardant DPMVSi, stir evenly for 20min (to prevent the generation of air bubbles), then slowly add 0.5g accelerator, continue stirring for 5min, add 1g initiator, stir for another 5min, put it in a vacuum drying oven at room temperature , 0.08MPa vac...

Embodiment 2

[0032] Under the protection of nitrogen, add 0.1mol PEPA, 0.1mol triethylamine, 100ml acetonitrile to the reaction flask equipped with magnetic stirring, reflux condensing device and drying protection device, raise the temperature to 60°C, and start dropping 0.05 mol of methyl vinyl dichlorosilane, 1 ~ 2h drop completely. Then the temperature was raised to 70°C for 2h, and then raised to reflux temperature for 6h, the reaction was stopped and cooled to room temperature. Filter, wash with ether and methanol, and dry at 80°C under 0.1MPa vacuum for 10 hours to obtain the target flame retardant DPMVSi.

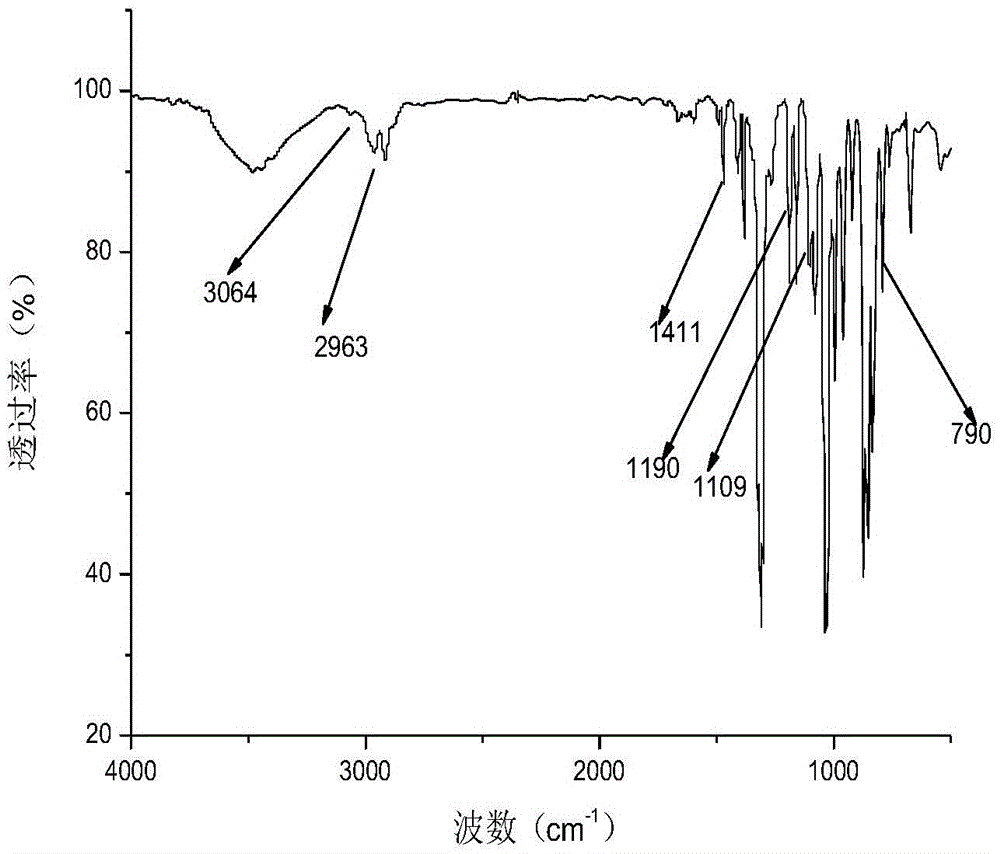

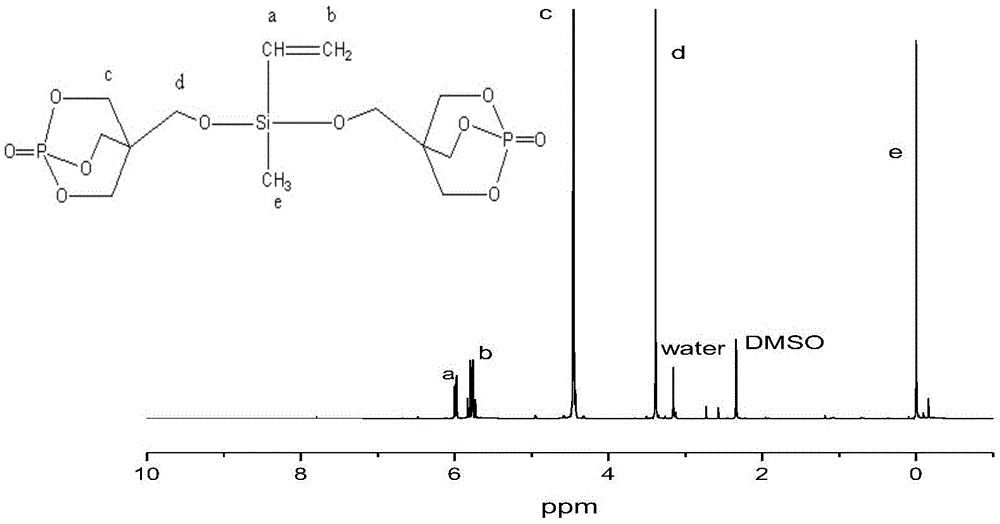

[0033] attached figure 1 It is the infrared spectrogram of the target flame retardant DPMVSi that the present embodiment makes; Among the figure: 3064cm -1 for -CH=CH 2 The stretching vibration absorption peak of C-H in , 2963cm -1 for -CH 3 The stretching vibration absorption peak of the , 1411cm -1 for -CH=CH 2 scissor vibration absorption peak, 1190cm -1 It is the stre...

Embodiment 3

[0038] Under the protection of nitrogen, add 0.15mol PEPA, 0.15mol triethylamine, 150ml acetonitrile to the reaction flask equipped with magnetic stirring, reflux condensing device and drying protection device, raise the temperature to 55 °C, and start dropping 0.06 mol of methyl vinyl dichlorosilane, 1 ~ 2h drop completely. Then the temperature was raised to 75° C. for 2 h, then raised to reflux temperature for 6 h, the reaction was stopped and cooled to room temperature. Filter, wash with ether and methanol, and dry at 80°C under 0.1MPa vacuum for 10 hours to obtain the target flame retardant DPMVSi.

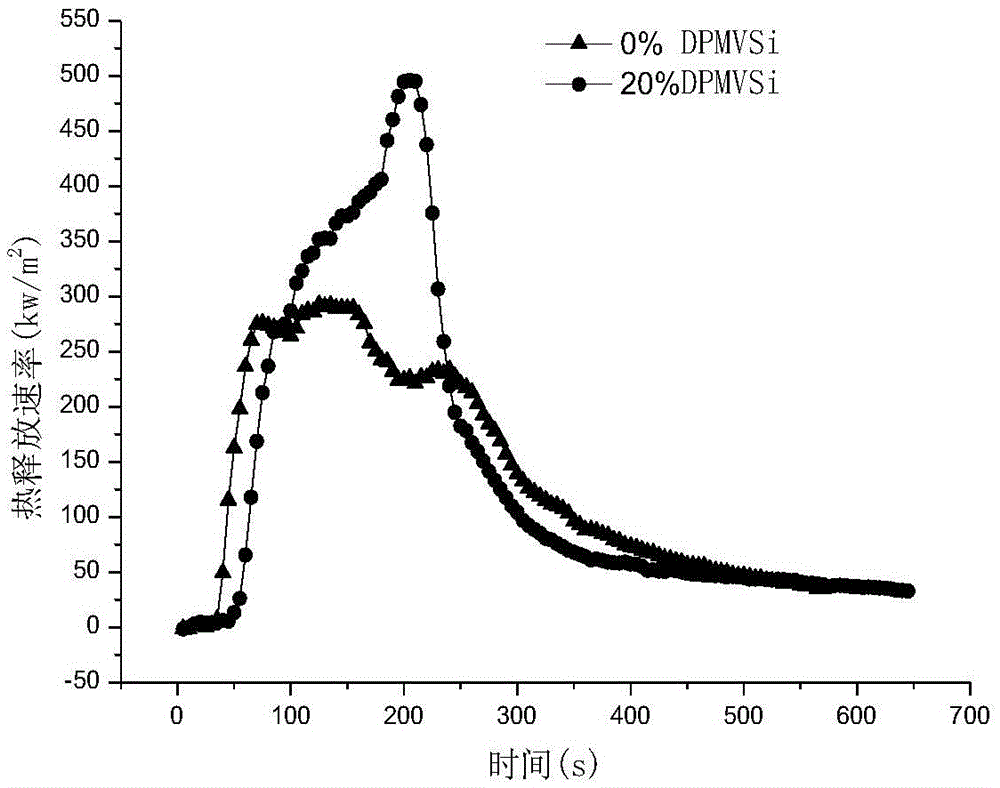

[0039] Add 70g of 196 to a 250ml beaker at room temperature # Pure unsaturated polyester and 30g target flame retardant DPMVSi, stir evenly for 20min (to prevent the generation of air bubbles), slowly add 0.9g accelerator, continue stirring for 5min, then add 1.8g initiator, stir for another 5min and put in vacuum Defoaming treatment was carried out in a drying oven at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com