A kind of etching solution for oxide material system and its etching method and application

A technology of etching solution and oxide, applied in chemical instruments and methods, surface etching composition, cable/conductor manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Choose to be deployed into novel etching solution by phosphoric acid, polyethylene glycol and water, wherein the preferred concentration of phosphoric acid is 0.01-80wt%, the preferred concentration of polyethylene glycol is 0.1-80wt%, the preferred water content for dilution is 10- 90wt%. The proportions of different formulations of each component directly affect the rate and etching effect of etching, but all have better etching effects. In this embodiment, the new etching solution consists of 25% polyethylene glycol, 25% phosphoric acid and 50% % of water composition, using mass spectrometry (MS), infrared spectrometry (IR) and energy spectrum analysis (EDS) and other test methods to determine the composition.

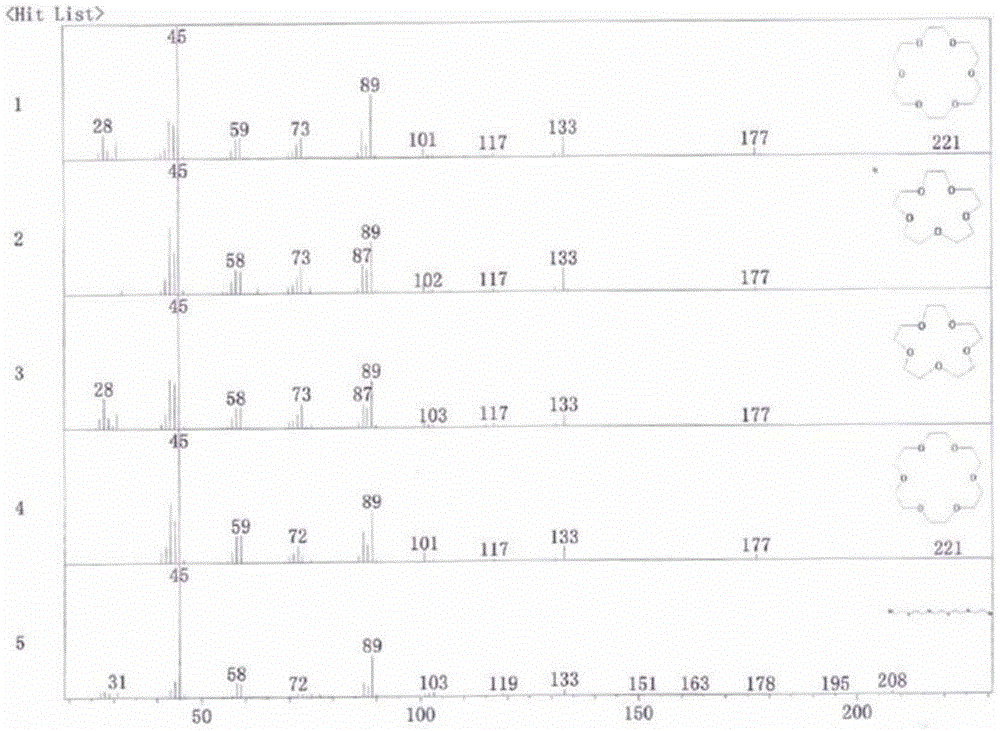

[0090] Obtain the mass spectrum of the liquid to be tested by mass spectrometry, such as figure 1 As shown, after searching by mass spectrometer, the composition of similar substances in the mass spectrum obtained from the sample is obtained from high to low...

Embodiment 2

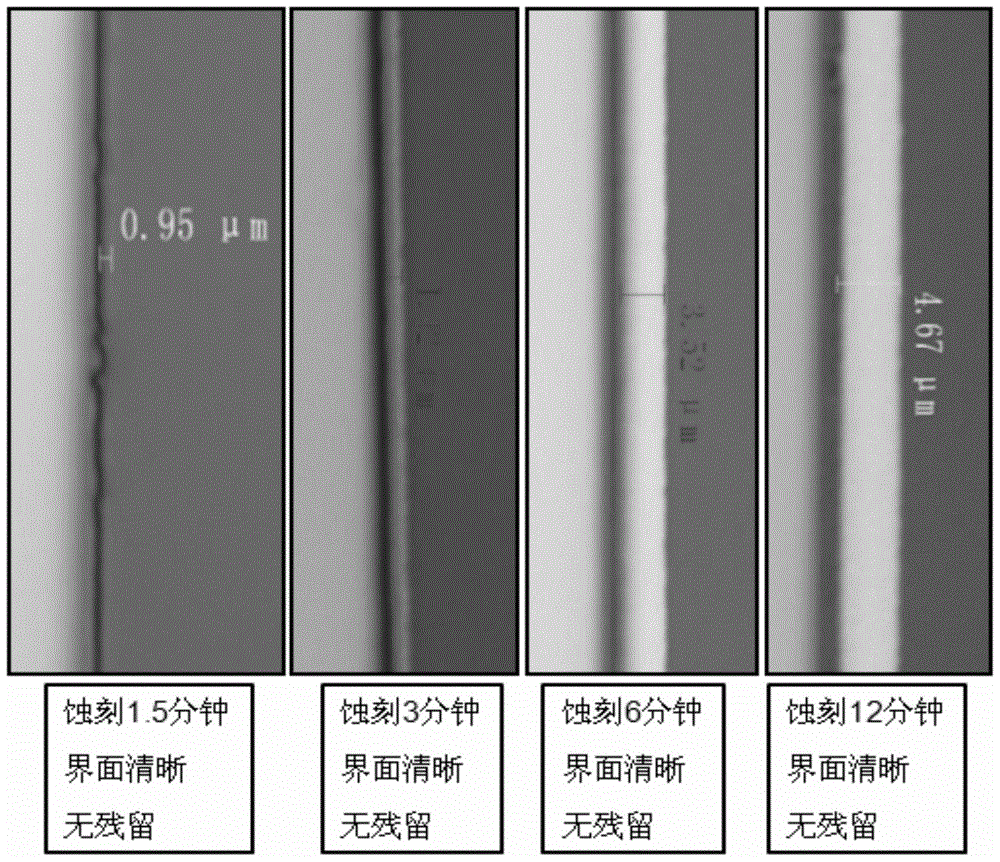

[0100] The traditional etchant is in the form of a solution. When etching the oxide material, the oxide material is immersed in the solution to react, which is called "soaking" etching method; and for the colloidal new etchant of the present invention, it can be The oxide material is etched by means of spin coating or spraying, and the method of spin coating or spraying is called "coating" etching mode herein.

[0101] In the "coating" etching method of the present invention, the process is to coat the new etching solution on the oxide film material with a photoresist pattern formed by using photoresist glue by spin coating or spraying, and the new etching solution coating The exposed oxide film material is etched, and after the etching is completed, the residual etching solution is removed with deionized water, and the coating can be etched repeatedly.

[0102] The "coating" etching method that the present invention adopts here, can adopt general-purpose spin coating or spray...

Embodiment 3

[0122] The application of the novel etching solution of the present invention will be described through this embodiment.

[0123] The above-mentioned features of the novel etching solution of the present invention are extremely useful for etching fine semiconductor optoelectronic devices, solar cells, TFT thin film transistors, semiconductor integrated circuits and transparent electrodes prepared by "oxide material system".

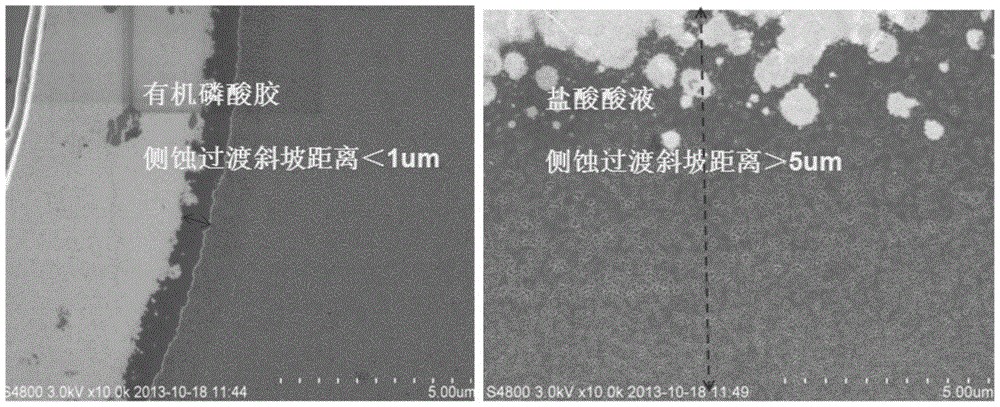

[0124] The new etchant is applied to the etching of oxide materials in semiconductor optoelectronic devices. Al, Ga, Zn, In-based oxide thin film materials are typically used in device applications, typically AZO, GZO, IZO or their combination components, as Transparent conductive films for optoelectronic devices such as LEDs and solar cells, or transparent electrodes for electronic devices such as TFT in the display field, or interconnect electrode materials for transparent electronics and other fields. These device fields all require the etching of oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com