A method for preparing vanadium oxide nanoparticle arrays by rapid thermal treatment

A vanadium oxide nanometer and rapid heat treatment technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long preparation period and complicated method process, and shorten the experimental period and process conditions Less, highly ordered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

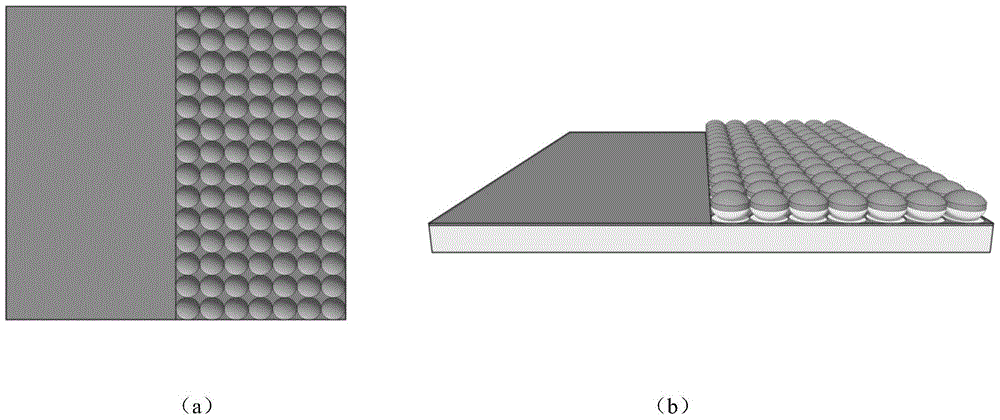

[0030] Schematic diagram of vanadium oxide nanoparticle array figure 1 shown.

[0031] 1) Soak a square aluminum oxide substrate with a size of 1cm×1cm in absolute ethanol, ultrasonically clean it for 20 minutes, rinse it with deionized water, pour an appropriate amount of acetone into it for ultrasonic cleaning for 20 minutes, and rinse it with deionized water Clean and dry; put glass slides (2cm×2cm) in acetone and absolute ethanol for ultrasonic cleaning for 25 minutes respectively, then rinse with deionized water, and put 10% sodium lauryl sulfate prepared previously after rinsing Soak in (SDS) solution for 24h, then rinse with deionized water, and the cleaned glass slide is used as a drainage piece in the process of adding the silica ball solution;

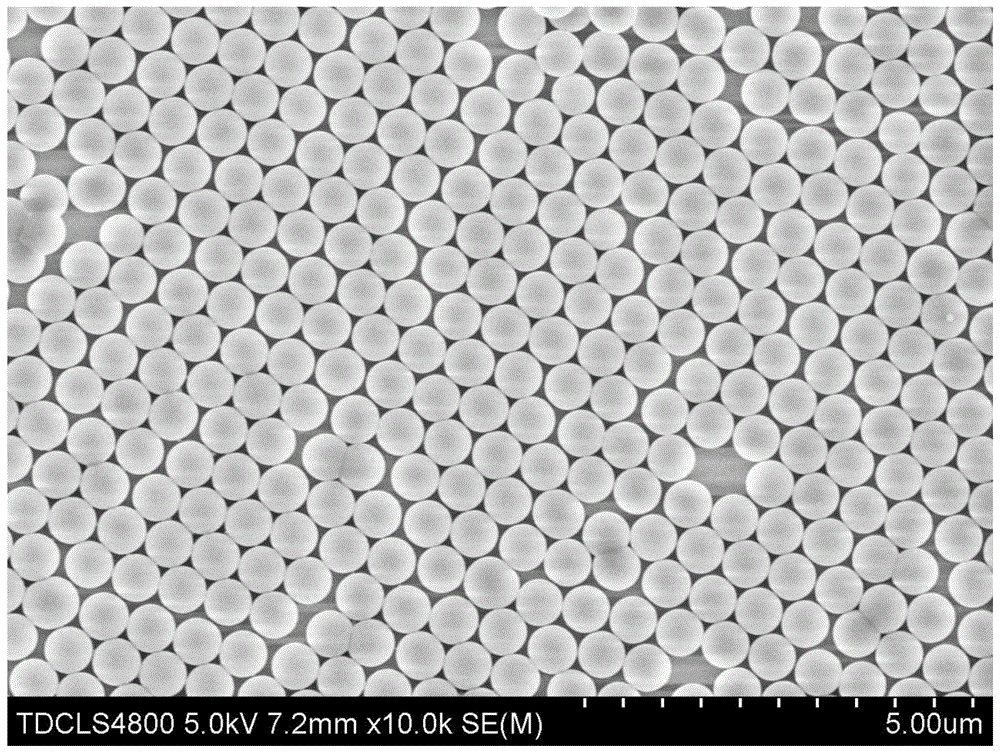

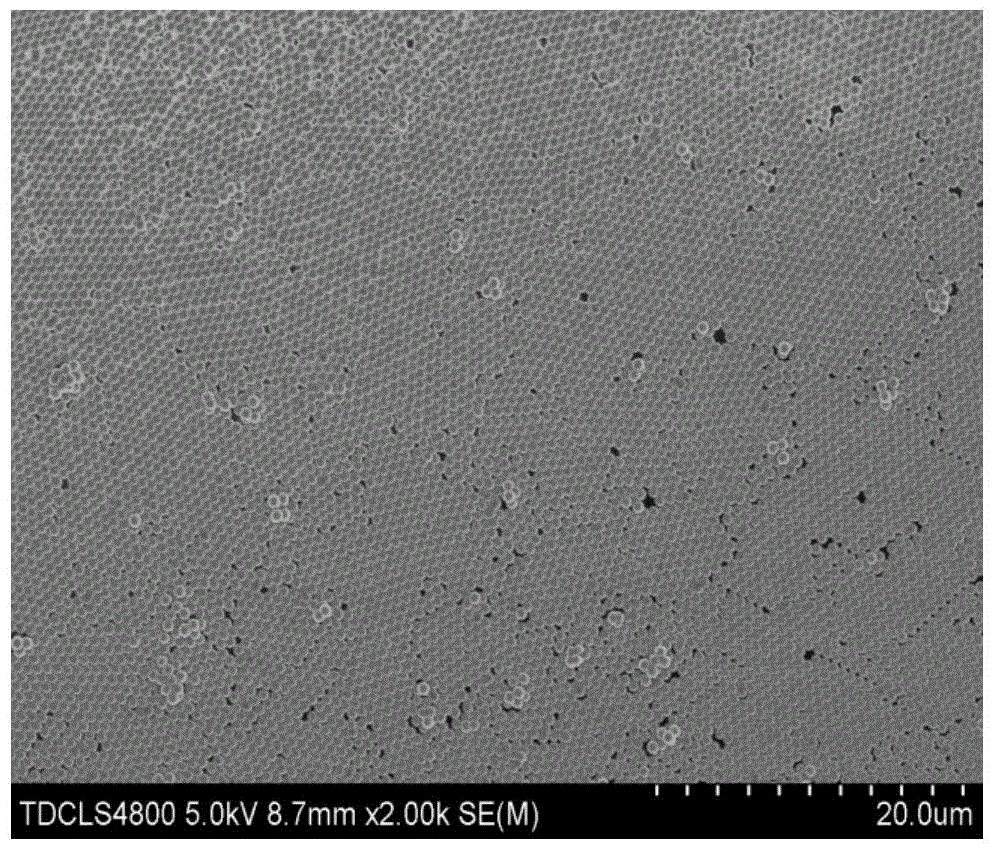

[0032] 2) Use a syringe to drop the silica-absolute ethanol solution onto the drainage sheet inserted obliquely into the deionized water, and slowly flow to the water surface, spread out on the water surface to form a high-d...

Embodiment 2

[0037] Schematic diagram of vanadium oxide nanoparticle array Figure 5 shown.

[0038] 1) Soak a square aluminum oxide substrate with a size of 1cm×1cm in absolute ethanol, ultrasonically clean it for 20 minutes, rinse it with deionized water, pour an appropriate amount of acetone into it for ultrasonic cleaning for 20 minutes, and rinse it with deionized water Clean and dry; put glass slides (2cm×2cm) in acetone and absolute ethanol for ultrasonic cleaning for 25 minutes respectively, then rinse with deionized water, and put 10% sodium lauryl sulfate prepared previously after rinsing Soak in (SDS) solution for 24h, then rinse with deionized water, and the cleaned glass slide is used as a drainage piece in the process of adding the silica ball solution;

[0039] 2) Use a syringe to drop the silica-absolute ethanol solution onto the drainage sheet inserted obliquely into the deionized water, and slowly flow to the water surface, spread out on the water surface to form a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com