Carbon-loaded silica nanoparticle structure as well as preparation method and application thereof

A particle structure, nano-silicon technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of electrode capacity attenuation, stable nano-silicon, high cost, and improve performance and stability. Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

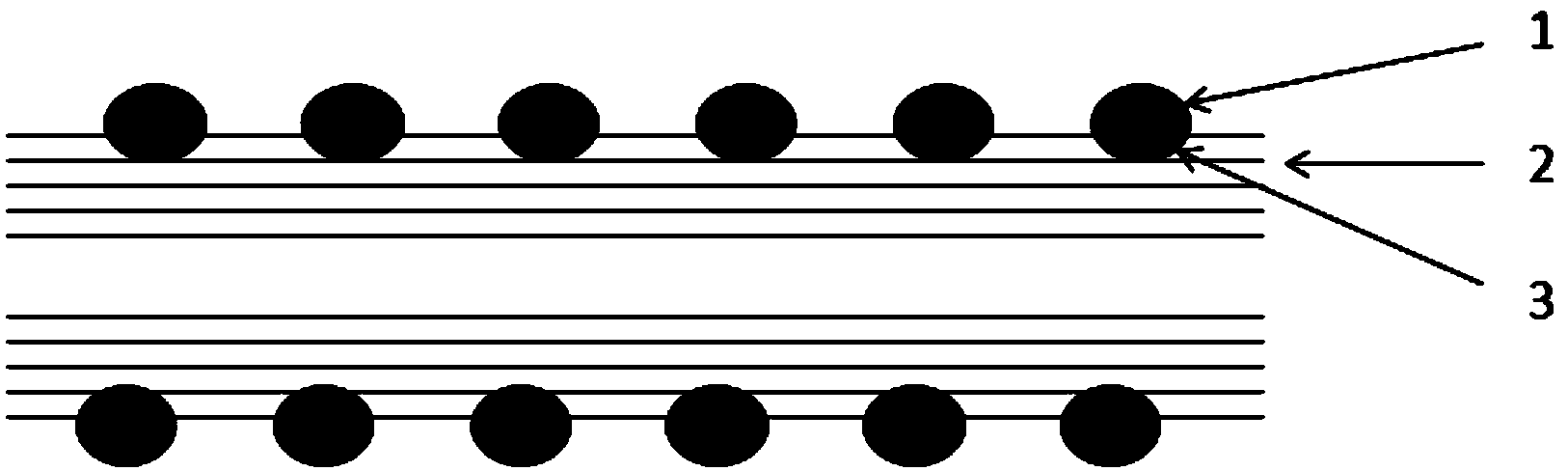

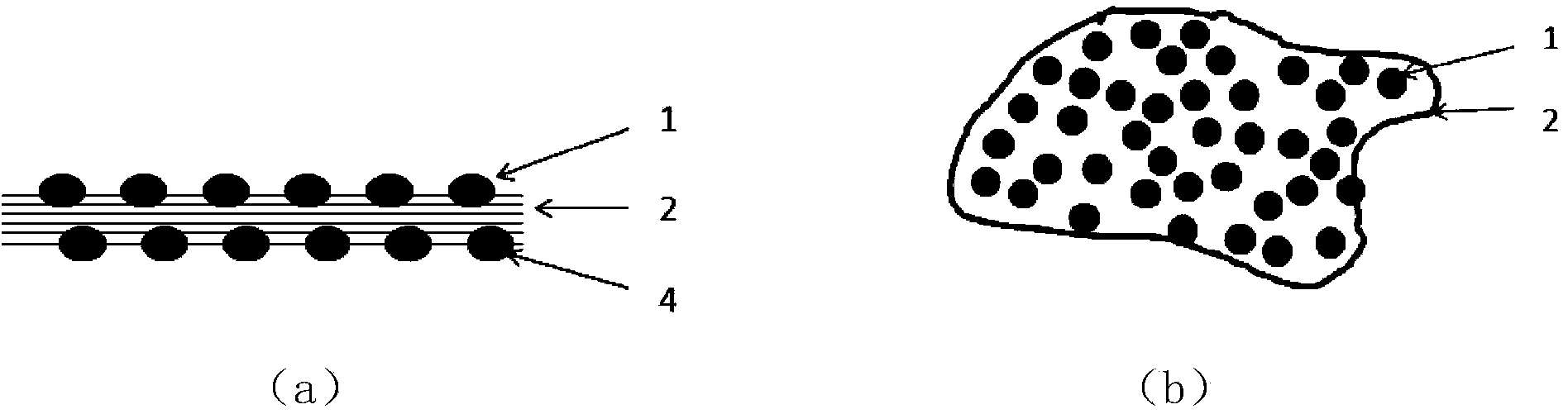

[0076] A method for preparing a carbon-supported nano-silicon particle structure provided by the invention comprises the following steps:

[0077] a) Nano-SiO 2 , magnesium powder and carbon are mixed to obtain mixture A, and the mixing method is simple mechanical mixing or loading method to first load nano-silicon particles 1 on the surface of carbon 2, and then mechanically mix with magnesium powder, wherein nano-SiO 2 The weight ratio with magnesium powder ≥ 1.24; nano-SiO 2 The weight ratio of carbon to carbon is between 2:9 and 6:1, preferably between 2:5 and 4:1, and most preferably between 1:2 and 2:1 to obtain mixture A; wherein nano-SiO 2Including, but not limited to, Aerosil Fumed Silica, such as untreated HP-60, M-5, H-5, HS-5, EH-5 and surface treated The TS-530,610, TS720; the surface hydrophilic Aerosil200, Aerosil255, Aerosil300, Aerosil380 and the surface lipophilic Aerosil R202, Aerosil R208, Aerosil R106, Aerosil R812 produced by the German company EVONIK; ...

Embodiment 1

[0083] 1. Preparation of nano-graphite microflakes (NanoG)

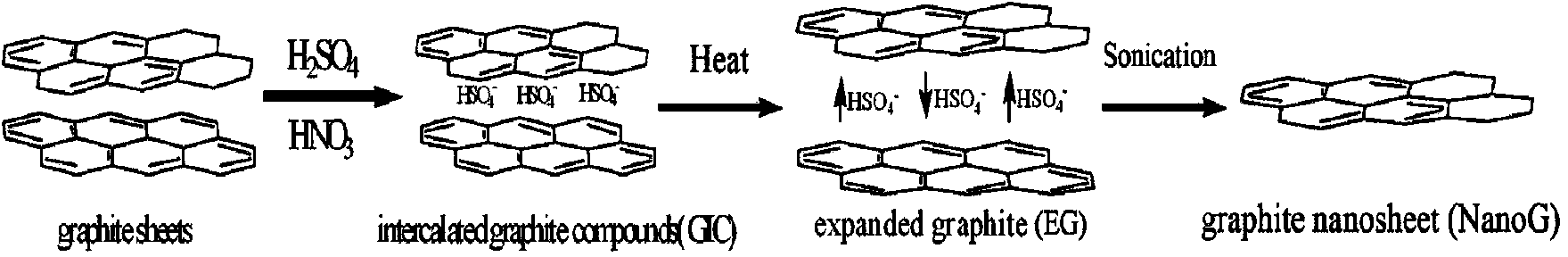

[0084] see image 3 , first use strong acid to oxidize and intercalate natural flake graphite to prepare graphite intercalation compound (GIC), and then quickly treat GIC at high temperature, the acid radical ions in the interlayer of GIC quickly decompose and expand, resulting in the increase of graphite interlayer spacing and the formation of expanded graphite (EG), immerse EG in 1-methyl-2-pyrrolidone (NMP), and ultrasonically treat it for a certain period of time, so that the solvent in the EG forms bubbles and breaks up, producing an instant strong shock wave, forming a high-speed jet, making the microscopic particles on the EG The flake structure was completely exfoliated, and free nano-graphite microflakes (NanoG) were prepared.

[0085] (2) see Figure 4 , Preparation of nano-silicon / nano-graphite microflake composites

[0086] a), nano-graphite microflakes, nano-SiO 2 Mechanically mix with magnesium powd...

Embodiment 2

[0092] 1. Preparation of nano-graphite microflakes (NanoG)

[0093] see image 3 , first use strong acid to oxidize and intercalate natural flake graphite to prepare graphite intercalation compound (GIC). Then the GIC is rapidly treated at high temperature, and the acid radical ions between the layers in the GIC are rapidly decomposed and expanded, resulting in an increase in the interlayer spacing of graphite and the formation of expanded graphite (EG). Immerse EG in 1-methyl-2-pyrrolidone (NMP) and ultrasonically treat it for a certain period of time, so that the solvent in the EG forms bubbles and breaks up, producing an instant strong shock wave and forming a high-speed jet, which makes the microchip structure on the EG completely fall off , to prepare free nano-graphite microflakes (NanoG).

[0094] (2) see Figure 4 , Preparation of nano-silicon / nano-graphite microflake composites

[0095] a), nano-graphite microflakes, nano-SiO 2 and magnesium powder in accordance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com