Cylindrical lithium ion battery and manufacturing method thereof

A technology of lithium ion battery and manufacturing method, applied in electrolyte battery manufacturing, battery electrode, secondary battery and other directions, can solve the problems of layered structure collapse, material capacity degradation, etc., to achieve lower internal resistance, higher specific capacity, and improved cycle The effect of capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

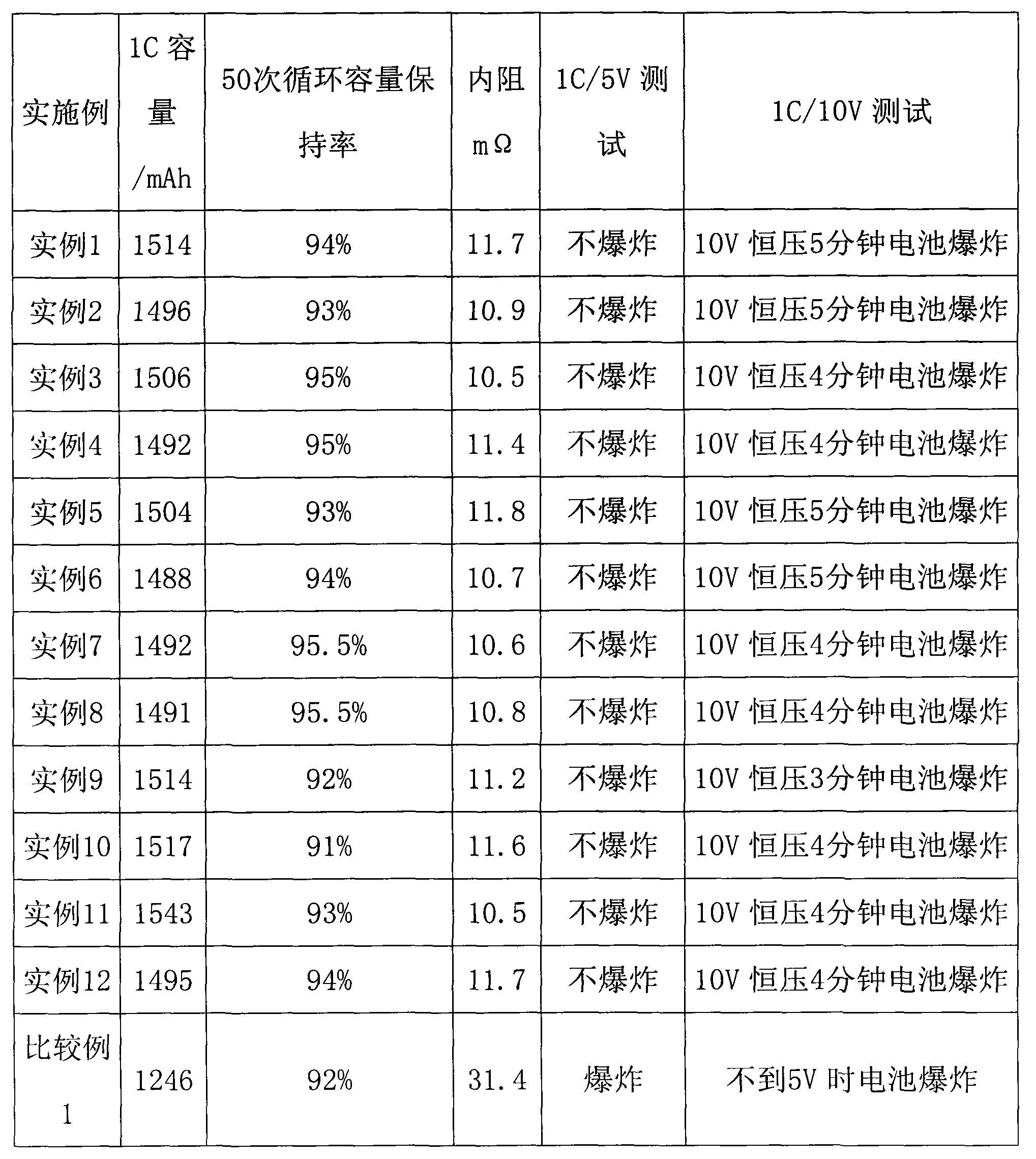

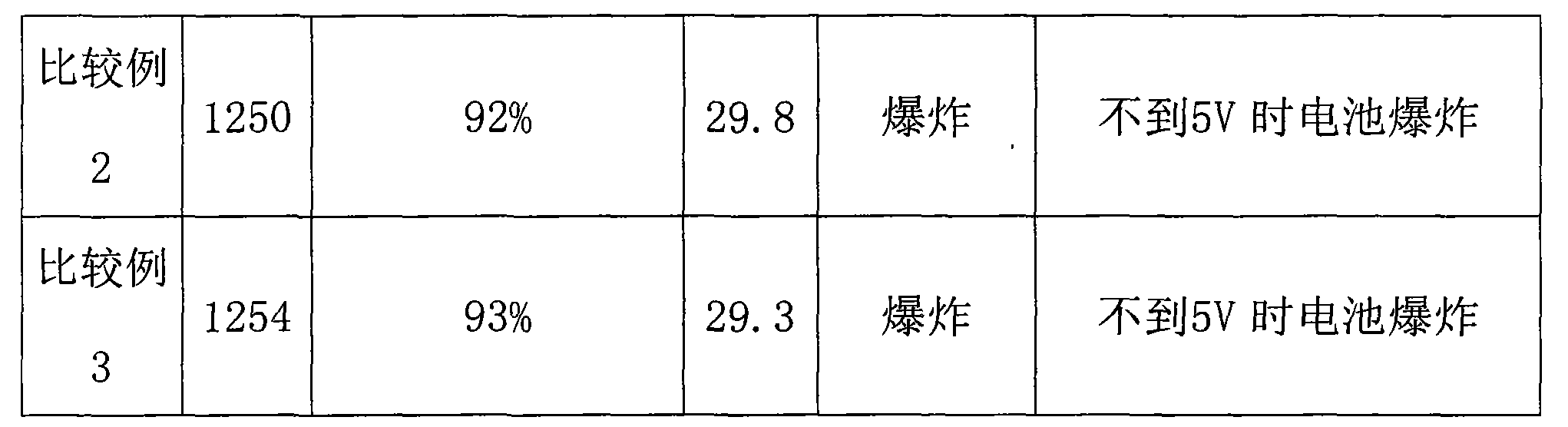

Examples

Embodiment 1

[0031] Lithium cobalt oxide (LiCoO 2 ) powder with 0.0121wt% indium oxide, at this moment, the mass fraction of elemental indium in indium-doped lithium cobalt oxide is 0.005%, and 0.05wt% dispersant is used as medium for grinding and mixing with alcohol and agate balls, material: balls : The alcohol ratio is 1: 2: 1.5 (mass ratio), put it into a star-shaped ball mill jar, grind and mix the materials for 30 minutes, put it into a microwave oven and dry it, and then make the indium-doped lithium cobalt oxide positive electrode material. The positive electrode material, acetylene carbon black as the conductive agent, and polyvinylidene fluoride (PVDF) binder were made into a slurry in a ratio of 94:3.5:2.5 by mass percentage, and evenly coated on a 20 μm thick aluminum foil. into a positive plate.

[0032] Mix the negative electrode active material small particle size artificial graphite, acetylene carbon black, and polyvinylidene fluoride (PVDF) binder in a ratio of 94:3.5:2.5...

Embodiment 2

[0034] Lithium cobalt oxide (LiCoO 2) powder with 14.49% indium oxide. At this time, the mass fraction of element indium in indium-doped lithium cobaltate is 6%, and alcohol and agate balls are used as media for grinding and mixing. The ratio of material: ball: alcohol is 1: 2: 1.5 (mass ratio), put it into a star-shaped ball mill jar, grind and mix the materials for 30 minutes, then put it into a microwave oven to dry, and then make an indium-doped lithium cobalt oxide cathode material.

[0035] The steps of preparing positive electrode sheet, negative electrode sheet and battery assembly and molding are the same as in Example 1.

Embodiment 3

[0037] In lithium cobalt oxide (LiCoO 2 ) powder with 0.024% indium oxide, at this time, the mass fraction of element indium in indium-doped lithium cobalt oxide is 0.01%, and alcohol and agate balls are used as media for grinding and mixing, and the ratio of material: ball: alcohol is 1:2: 1.5 (mass ratio), put it into a star-shaped ball mill jar, grind and mix the materials for 30 minutes, then put it into a microwave oven to dry, and then make an indium-doped lithium cobalt oxide cathode material.

[0038] The steps of preparing positive electrode sheet, negative electrode sheet and battery assembly and molding are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com