Method and device for purifying nitric oxide and fog particles in wet desulphurization aerial fog by low-temperature plasma

A low-temperature plasma and wet desulfurization technology, which is applied to chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of low denitrification efficiency, inability to efficiently oxidize NO, and weak high-energy electronic chemical effects, so as to reduce investment and running cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

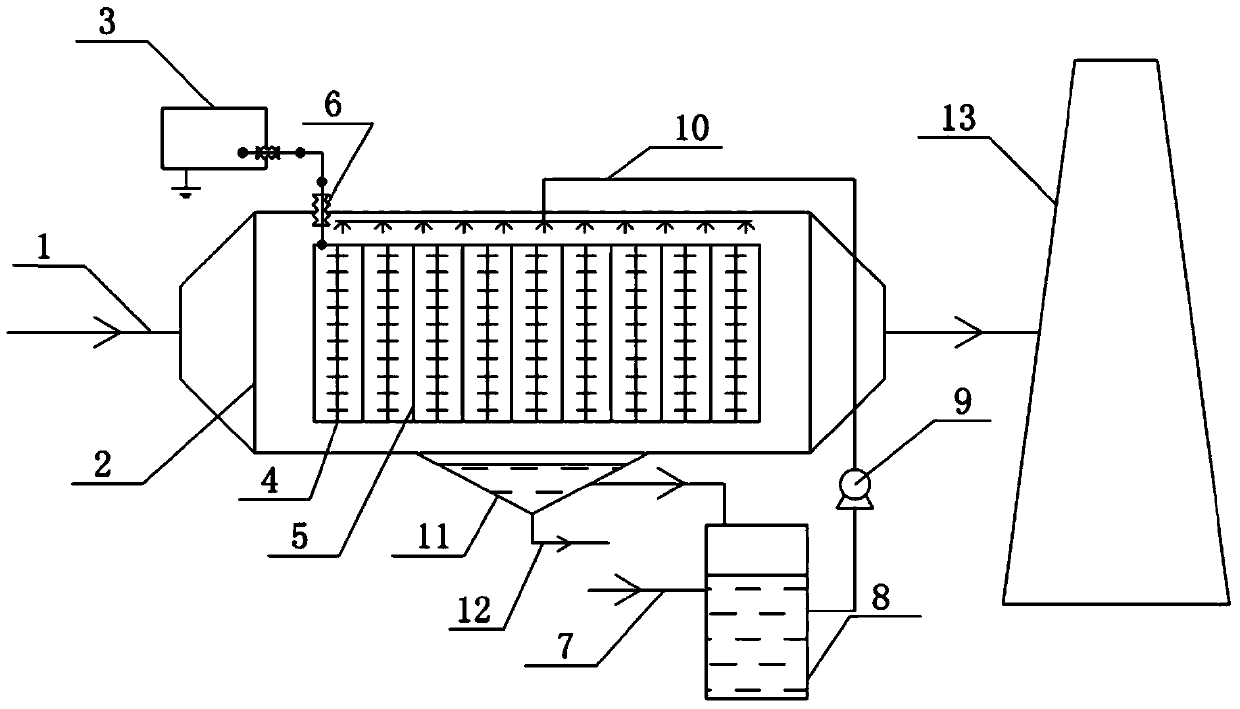

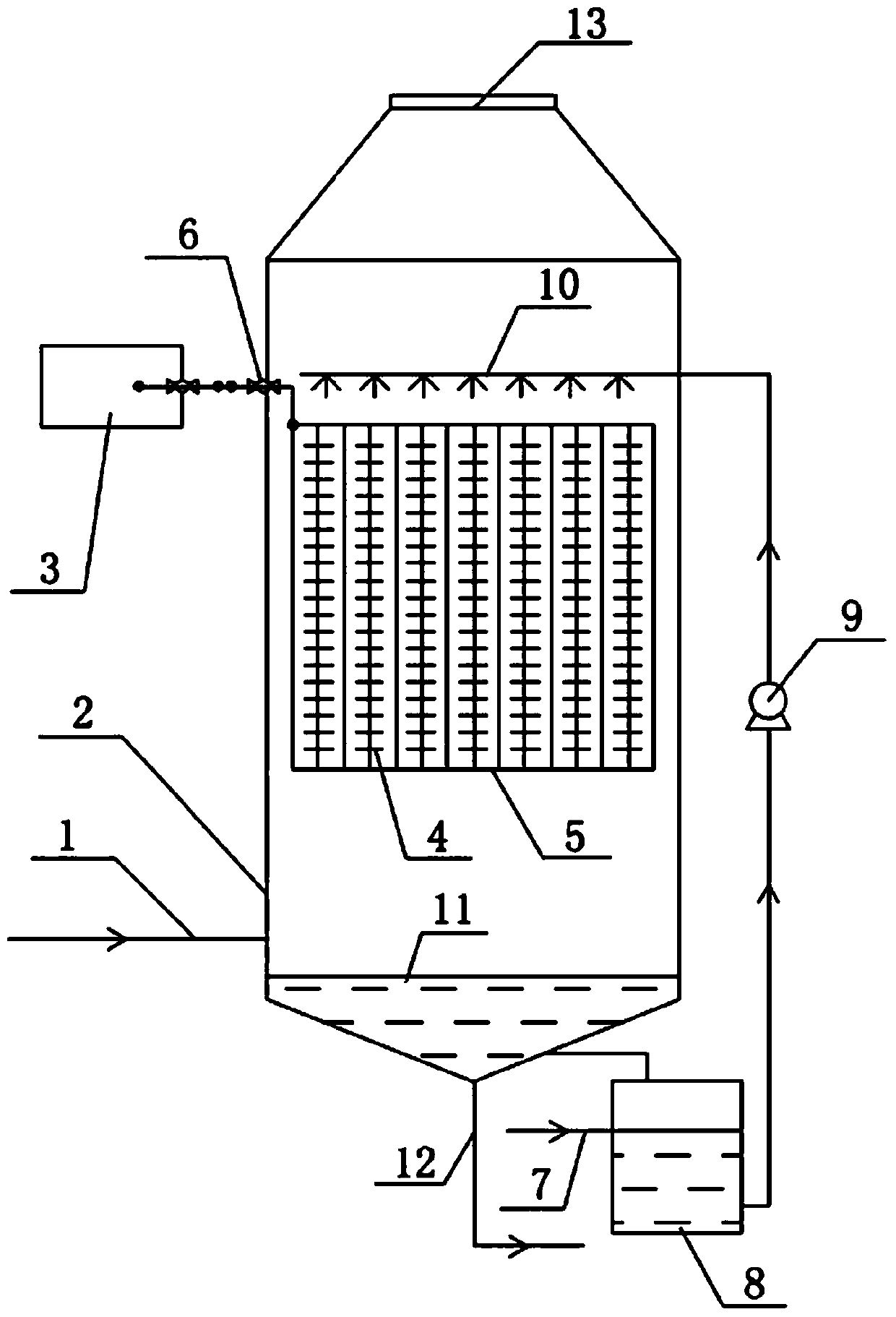

[0027] Apply the device provided by the present invention to purify nitrogen oxides and mist particles in the wet desulfurization gas mist by using low-temperature plasma, the discharge electrode 4 adopts a zigzag shape, the ground electrode 5 is in the shape of a W-shaped plate, and the high-voltage power supply 3 is a positive DC high voltage Power supply, the discharge voltage is 50kV; use the purification device based on this configuration to process the wet desulfurization gas mist of a chemical company boiler, and the gas volume is 160000Nm 3 / h. The test results show that the removal efficiency of mist particles is higher than 97.3%, and the removal efficiency of nitric oxide is higher than 60.6%.

Embodiment 2

[0029] The discharge electrode 4 adopts a zigzag shape, the ground electrode 5 is a Z-shaped plate, the high-voltage power supply 3 is a positive DC high-voltage power supply, and the discharge voltage is 20kV; the purification device based on this configuration is used to treat the boiler wet desulfurization gas mist of an electric company , the processing gas volume is 122000Nm 3 / h. The test results show that the removal efficiency of mist particles is higher than 96.5%, and the removal efficiency of nitric oxide is higher than 72%.

Embodiment 3

[0031] The discharge electrode 4 adopts the shape of serially connected gears (four teeth are uniformly distributed on each gear), the ground electrode 5 is a cylindrical honeycomb body, and the high-voltage power supply 3 is a positive DC high-voltage power supply superimposed with a high-frequency AC power supply, wherein the positive polarity The DC working voltage is 70kV; the purification device based on this configuration is used to treat the boiler wet desulfurization gas mist of a petrochemical company, and the gas volume is 800000Nm 3 / h. The test results show that the removal efficiency of mist particles is higher than 96%, and the removal efficiency of nitric oxide is higher than 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com