High-voltage-resistant high hardness cable sheath material

A cable sheath, high hardness technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of affecting the normal detection of cables, endangering the safety of cable operation, and easy damage to cable laying, achieving good surface smoothness and increasing service life. , The effect of improving scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

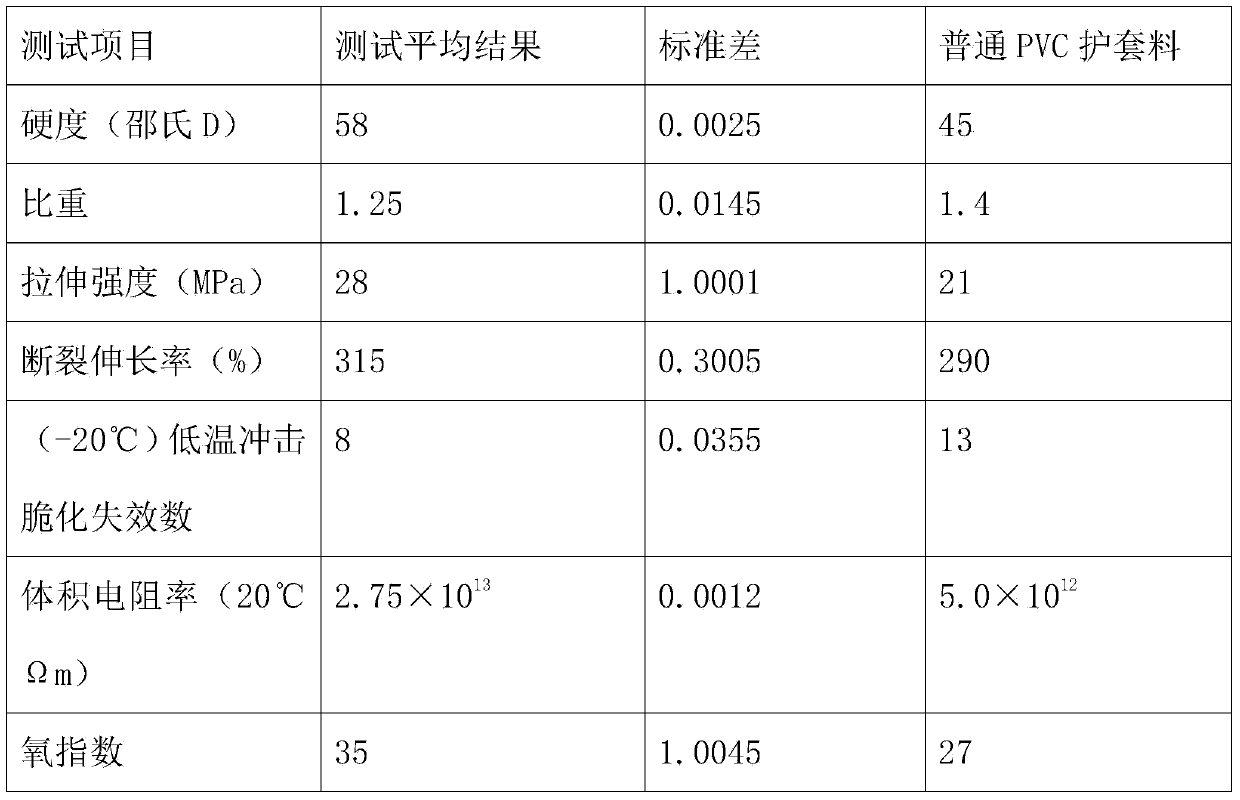

Embodiment 1

[0012] In this embodiment, a high-voltage-resistant high-hardness cable sheath material includes: weighing 45 parts of metallocene polyethylene, 21 parts of ethylene-vinyl acetate resin, 12 parts of aniline diphenyl ether resin, 6.5 parts Composite environment-friendly heat stabilizer, wherein the weight ratio of environment-friendly Ca / Zn composite stabilizer and epoxy soybean oil is 3.5:1.5, based on composite environment-friendly heat stabilizer 64wt% microencapsulated red phosphorus, 2 parts of expanded graphite, 0.4 1 part of polyethylene wax and 0.25 part of high-efficiency lubricant were placed in a low-speed kneader and stirred evenly to obtain material A; 25wt based on the total weight of metallocene polyethylene, ethylene-vinyl acetate resin and aniline diphenyl ether resin % phthalates, 4.5wt% graphite, 30wt% conductive metal powder based on graphite, 40wt% calcined clay based on polyethylene wax, equivalent to 45% magnesium methacrylate of composite environmental pr...

Embodiment 2

[0014] In this embodiment, a high-voltage-resistant high-hardness cable sheath material includes: weighing 51 parts of metallocene polyethylene, 20 parts of ethylene-vinyl acetate resin, 14 parts of aniline diphenyl ether resin, 7 parts Composite environment-friendly heat stabilizer, wherein the weight ratio of environment-friendly Ca / Zn composite stabilizer and epoxy soybean oil is 3.8:1, based on the composite environment-friendly heat stabilizer, 70wt% microencapsulated red phosphorus, 5 parts of expanded graphite, 0.35 1 part of polyethylene wax and 0.2 part of high-efficiency lubricant were placed in a low-speed kneader and stirred evenly to obtain material A; 45wt based on the total weight of metallocene polyethylene, ethylene-vinyl acetate resin and aniline diphenyl ether resin was weighed % phthalates, 6.5wt% graphite, 15wt% conductive metal powder based on graphite, 85wt% calcined clay based on polyethylene wax, equivalent to 27% magnesium methacrylate of composite env...

Embodiment 3

[0016] In this embodiment, a high-voltage-resistant high-hardness cable sheath material includes: weighing 48 parts of metallocene polyethylene, 18 parts of ethylene-vinyl acetate resin, 16 parts of aniline diphenyl ether resin, 5 parts Composite environment-friendly heat stabilizer, wherein the weight ratio of environment-friendly Ca / Zn composite stabilizer and epoxy soybean oil is 3.65:1.25, based on composite environment-friendly heat stabilizer 60wt% microencapsulated red phosphorus, 3.5 parts of expanded graphite, 0.2 1 part of polyethylene wax and 0.27 part of high-efficiency lubricant were placed in a low-speed kneader and stirred evenly to obtain material A; the total weight of metallocene polyethylene, ethylene-vinyl acetate resin and aniline diphenyl ether resin was weighed to 31wt % phthalates, 2.5wt% graphite, 20wt% conductive metal powder based on graphite, 100wt% calcined clay based on polyethylene wax, equivalent to 32% magnesium methacrylate of composite environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com