Method for production of microalgal energy (biodiesel) raw material from Haematococcus sp.

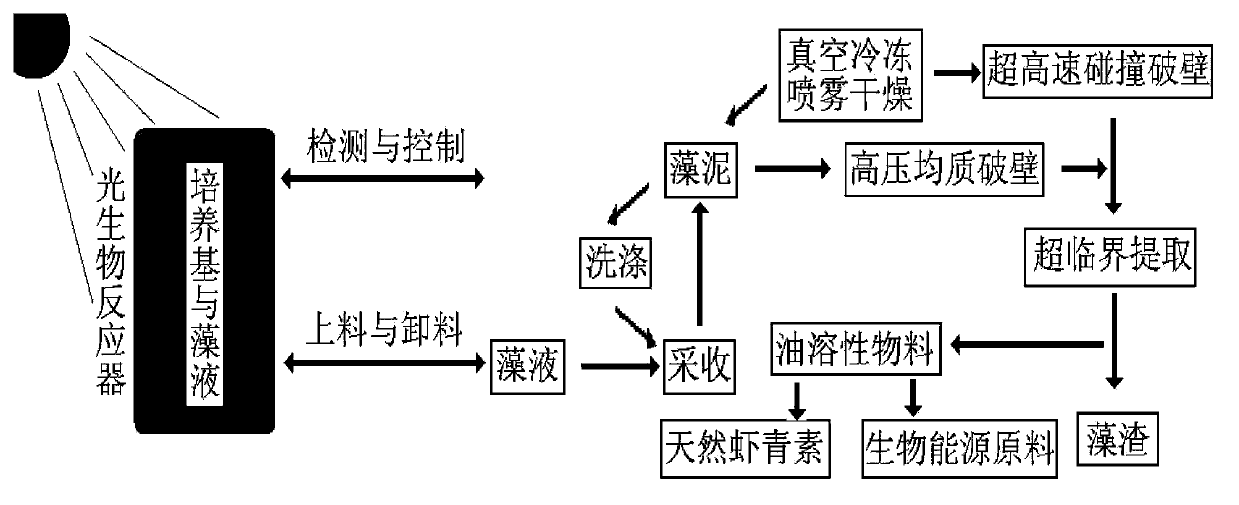

A technology of biodiesel and a process method is applied in the field of producing microalgae energy (biodiesel) raw materials, which can solve the problems of restricting the economic feasibility of industrial development and high production costs, and achieve the improvement of comprehensive utilization efficiency, reduction of production costs, and strong anti-oxidation. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

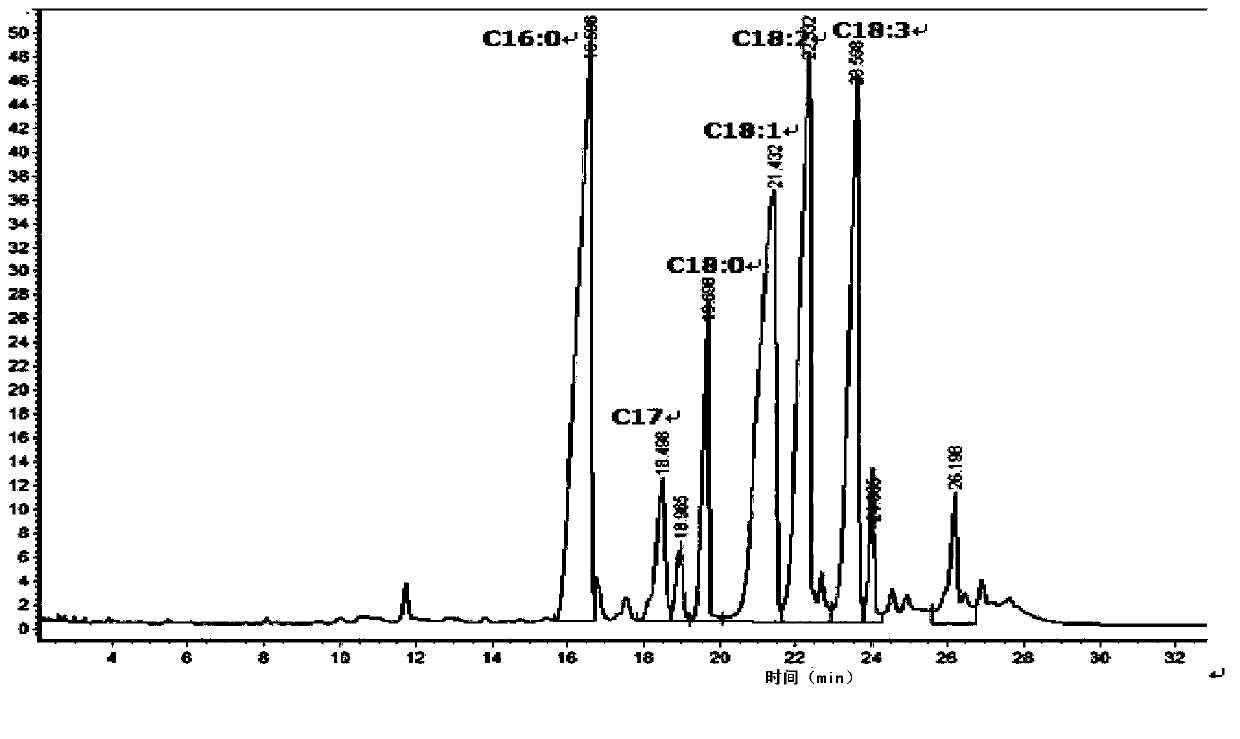

Embodiment 1

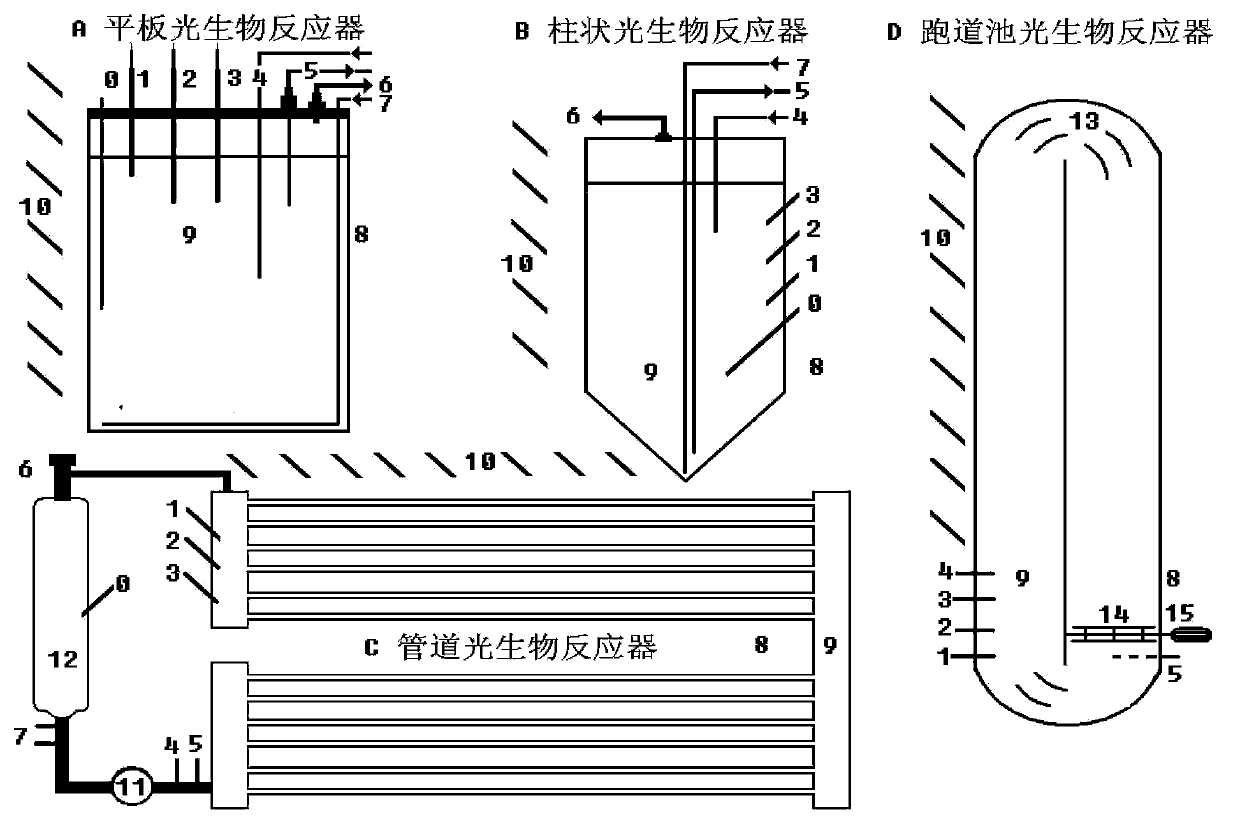

[0031] Select Haematococcus pluvialis, use the BG11 formula to make the medium (see Table 1), under the condition of 22-25°C, and indoor natural diffuse light with the aid of 50μE·m 2- ·s -1 The light intensity of the light is illuminated, and the Haematococcus algae are cultivated according to the light and dark rhythm of 14:10.

[0032] After the Haematococcus species were cultured for 12 days, the cells were in the logarithmic growth phase of rapid reproduction. Inoculate the algae species into the columnar photobioreactor, which contains the medium made by BG11 formula, and then continue to cultivate in the cultivation workshop at 20-25°C. The cultivation adopts natural sunlight light source, and the light intensity can be adjusted and controlled by the sunshade , the intensity is 1000-2000μE·m 2- ·s -1 Within the range, continue to expand the culture for 2 weeks.

[0033] The expanded cultured Haematococcus algae strains are then transferred to the open runway pool bi...

Embodiment 2

[0035] Haematococcus pluvialis was selected as the algae strain, using the MCM medium formula (refer to Table 1), the temperature was at 20-23°C, the light was natural diffuse light in the room, and an auxiliary 70μE·m 2- ·s -1 LED lights with light intensity, light cycle 14:10 (light: dark) for algae cultivation.

[0036] The algae culture is in the logarithmic growth phase for 10 days. The algae species are inoculated into the columnar photobioreactor, and the medium formula is improved by using MCM. In the cultivation workshop at 20-23°C, natural light is used as the light source, and the light intensity is adjusted and controlled at 1200-2300μE·m 2- ·s -1 Within the range, continue to expand the culture for 10 days.

[0037] The enlarged cultured Haematococcus is then transferred into the open pipe photobioreactor through the pipeline system, and the MCM medium with nitrogen and phosphorus nutrition deficiency is used (see Table 1 for the specific formula, but the nitro...

Embodiment 3

[0039] Select Haematococcus pluvialis and use BBM medium to optimize the formula, at 21-24°C, indoor natural diffuse light assisted 70μE·m 2- ·s -1 Cultivate under the LED light of light intensity, and the light cycle during the cultivation is 14:10 (light: dark).

[0040] After 10 days of cultivation, inoculate the algal species in the logarithmic growth phase into a flat photobioreactor, use BBM to improve the medium formula, and use natural light as the light source in the cultivation workshop (algae liquid temperature 22-25°C), light Intensity adjustment control 1200-2000μE·m 2- ·s -1 , continue to expand and cultivate for 12 days.

[0041] The expanded cultured Haematococcus is then transferred to the bioreactor of the open room runway pool through the pipeline system. Use the BBM medium with nutrient deficiency (mainly nitrogen and phosphorus deficiency) (see Table 1 for the specific formula, but the nitrogen and phosphorus nutrients in it are not added) to induce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com