Medical titanium surface composite coating and preparation method thereof

A medical, titanium-based technology, which is applied in the field of medical titanium materials and its preparation, can solve the problems of unsatisfactory implant surface bioactivity, poor bone regeneration ability of hard tissue implants, and poor bonding of surrounding tissues, so as to prevent and treatment of infection, stable and controllable preparation process, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

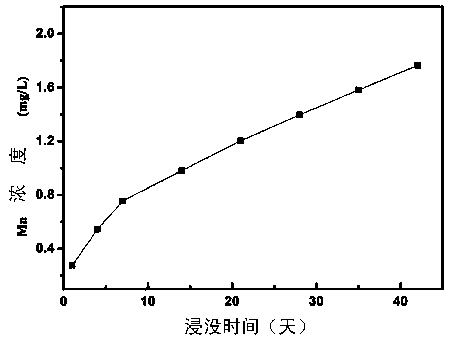

[0034] The present invention relates to a biomedical titanium material method with a bioceramic film layer, and more precisely relates to a densified titanium-based manganese-doped titanium oxide modification with excellent corrosion resistance, antibacterial and osteogenic properties. Sexual layer and its preparation method. The invention belongs to the technical field of biomedical ceramic modified layer. In order to solve the problems of poor antibacterial properties, osteogenic properties and corrosion resistance existing in the existing medical titanium materials, the present invention discloses a medical titanium material and a preparation method thereof, which have multifunctional densified manganese-doped titanium oxide modified The method includes preparing a manganese-containing densified titanium oxide modified layer by using micro-arc oxidation in a specific electrolyte. The corrosion resistance of the titanium metal material modified by the present invention has ...

Embodiment 1

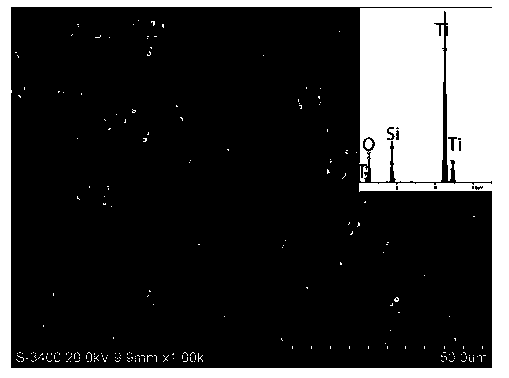

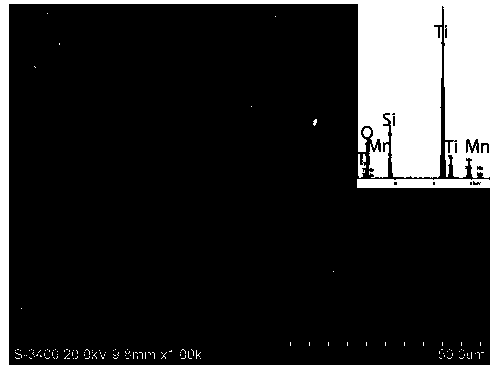

[0068] (a) Use deionized water to mix 1g / L potassium permanganate, 1g / L sodium hydroxide, 2g / L EDTA-Na 2 Mix with 24g / L sodium silicate to prepare electrolyte. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 20A / dm 2, frequency 800Hz, and duty cycle 10% under the conditions, react until the cut-off voltage is 380V, and keep the electrolyte temperature below 40°C. (c) After the sample was taken out, it was boiled in deionized water for 5 min and dried naturally. After testing, the thickness of the modified layer is about 1 μm, and the element composition is mainly Ti, O, Si, and Mn. X-ray diffraction analysis shows that the phase composition of the modified layer is mainly anatase and a small amount of TiO in the rutile phase. 2 , EDS results show that the content of manganese in the modified layer is about 0.6wt%, and SEM analysis shows that the pore size of the modified layer is less than 5 ...

Embodiment 2

[0076] (a) Using deionized water, mix 16g / L sodium glycerophosphate and 1g / L potassium permanganate to prepare an electrolyte solution. (b) With titanium as the anode and stainless steel as the cathode, a DC pulse power supply is used at a constant current density of 10A / dm 2 , frequency 800Hz, duty cycle 20% under the conditions, the reaction until the cut-off voltage is 410V, keep the electrolyte temperature below 40 ℃. (c) After the sample was taken out, it was boiled in deionized water for 5 min and dried naturally. After testing, the thickness of the modified layer is about 2 μm, and the element composition is mainly Ti, O, P, and Mn. X-ray diffraction analysis shows that the phase composition of the modified layer is mainly anatase TiO 2 and a small amount of rutile TiO 2 , EDS results show that the content of manganese in the modified layer is about 1wt%, and SEM analysis shows that the pore size of the modified layer is less than 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com