A kind of interpenetrating network polymer for paper reinforcement and preparation method thereof

An interpenetrating network and polymer technology, applied in the field of papermaking additives, can solve the problems of imperfect product performance, low wet strength performance, poor dispersion stability, etc., achieve stable and controllable preparation process, low production cost, and improve wet strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

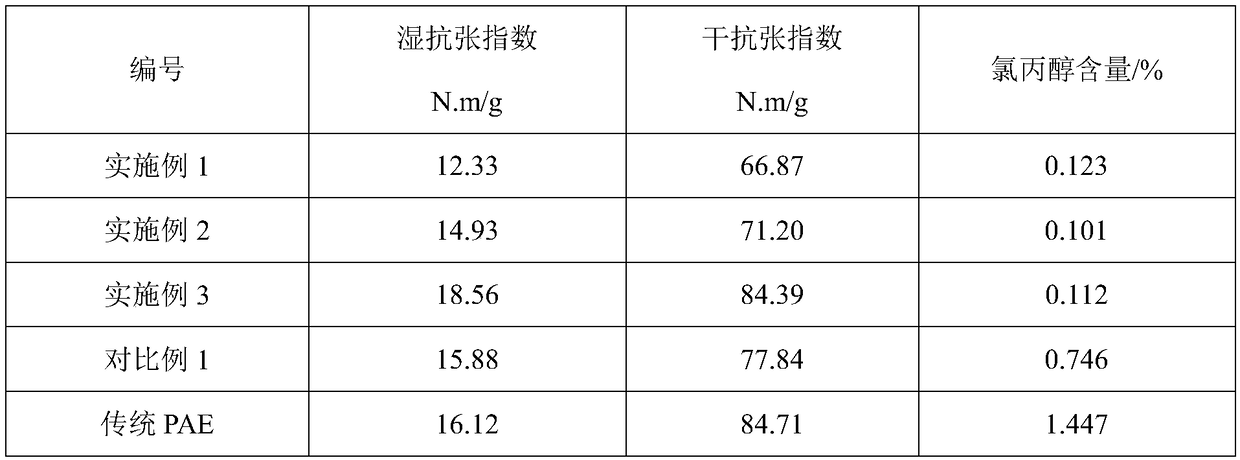

Examples

Embodiment 1

[0023] (1) Add 10 parts of reaction medium PAE resin, 10 parts of acrylamide monomer, 10 parts of dimethyl diallyl ammonium chloride monomer, 0.1 part of methylene bisacrylamide, 0.1 part of γ- Methacryloyloxypropyltrimethoxysilane, stirred evenly at 50°C, slowly added 0.18 parts of initiator aqueous solution (dissolved in 35 parts of water), dropwise for 60 minutes, and freely polymerized for 4 hours to obtain a polymer A;

[0024] (2) Add 5 parts of N,N-dimethylaminoethyl methacrylate, 5 parts of styrene, 5 parts of butyl acrylate, 5 parts of glacial acetic acid and 20 parts of DMF into the reactor. After stirring evenly, add 1 Parts of initiator AIBN were reacted at 80°C for 5 hours to obtain a yellow viscous polymer surfactant; 6 parts of polymer surfactant and 10 parts of polyisocyanate trimer were mixed evenly, and 40 parts of water were added to disperse and emulsify at a high speed to prepare A water-dispersible polyisocyanate crosslinking agent was obtained.

[0025...

Embodiment 2

[0027] (1) Add 30 parts of reaction medium PAE resin, 50 parts of acrylamide monomer, 7 parts of dimethyl diallyl ammonium chloride monomer, 0.5 part of methylene bisacrylamide, 0.3 part of γ- Glycidyl ether oxypropyltrimethoxysilane, stir evenly at 65°C, slowly add 0.5 parts of potassium persulfate-sodium bisulfite aqueous solution (dissolved in 45 parts of water), dropwise for 60 minutes, free polymerization for 4 hours , to obtain polymer A;

[0028] (2) Add 5 parts of N,N-dimethylaminoethyl methacrylate, 5 parts of styrene, 5 parts of butyl acrylate, 5 parts of glacial acetic acid and 20 parts of DMF into the reactor. After stirring evenly, add 1 Parts of initiator AIBN were reacted at 80°C for 5 hours to obtain a yellow viscous polymer surfactant; 6 parts of polymer surfactant and 10 parts of polyisocyanate trimer were mixed evenly, and 40 parts of water were added to disperse and emulsify at a high speed to prepare A water-dispersible polyisocyanate crosslinking agent w...

Embodiment 3

[0031] (1) Add 20 parts of reaction medium PAE resin, 20 parts of acrylamide monomer, 8 parts of dimethyl diallyl ammonium chloride monomer, 0.3 part of methylenebisacrylamide, 0.2 part of γ- Methacryloxypropyltrimethoxysilane, stirred evenly at 65°C, slowly added 0.3 parts of ammonium persulfate-sodium bisulfite initiator aqueous solution (dissolved in 40 parts of water), and the dropping time was 50 minutes. Free polymerization for 4 hours to obtain Polymer A;

[0032] (2) Add 5 parts of N,N-dimethylaminoethyl methacrylate, 5 parts of styrene, 5 parts of butyl acrylate, 5 parts of glacial acetic acid and 20 parts of DMF into the reactor. After stirring evenly, add 1 Parts of initiator AIBN were reacted at 80°C for 5 hours to obtain a yellow viscous polymer surfactant; 6 parts of polymer surfactant and 10 parts of polyisocyanate trimer were mixed evenly, and 40 parts of water were added to disperse and emulsify at a high speed to prepare A water-dispersible polyisocyanate cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com