Preparation technology of Ce-Zr-based oxygen-storage materials

A preparation process and technology for oxygen storage materials, applied in the field of preparation of oxygen storage materials, can solve problems such as increasing production costs and wasting energy, and achieve the effects of improving safety factor, reducing production costs, and being beneficial to large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

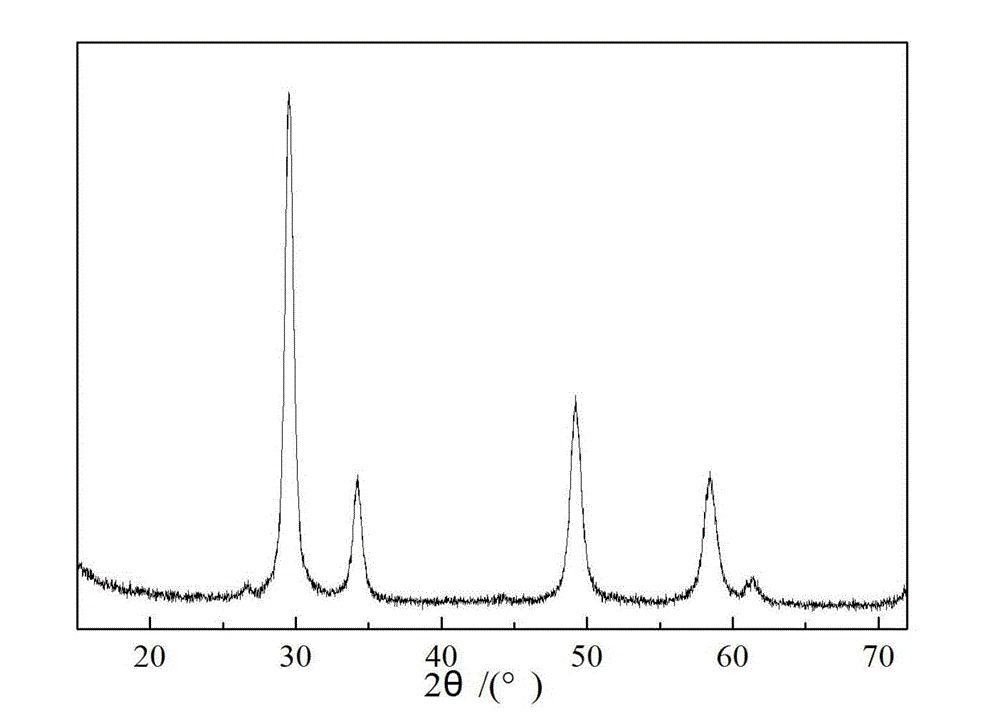

[0025] The carbonates of cerium, zirconium, lanthanum, yttrium, praseodymium, and neodymium were respectively dissolved in nitric acid until the solution was clear, adjusted according to the distribution, diluted with water to make the oxide mass concentration 150g / L, mixed evenly to obtain a mixed salt solution, added Hydrogen peroxide (the mass ratio of hydrogen peroxide to rare earth oxide is 1.35:1), stir evenly; add surfactant (oleic acid) into the ammonia water, stir evenly, drop the mixed salt solution into the ammonia water until the pH is 9-10 and the precipitation is complete After the end, while maintaining the precipitation temperature at 50 ° C. After the precipitation, the precipitate needs to be kept at 35°C for 2 hours, then washed, burned at 600°C for 10 hours, pulverized, mixed, and aged at 1000°C for 10 hours to obtain an aged product. The specific surface area and oxygen storage capacity data are shown in the table 1. The XRD spectrogram of the aging produ...

Embodiment 4-6

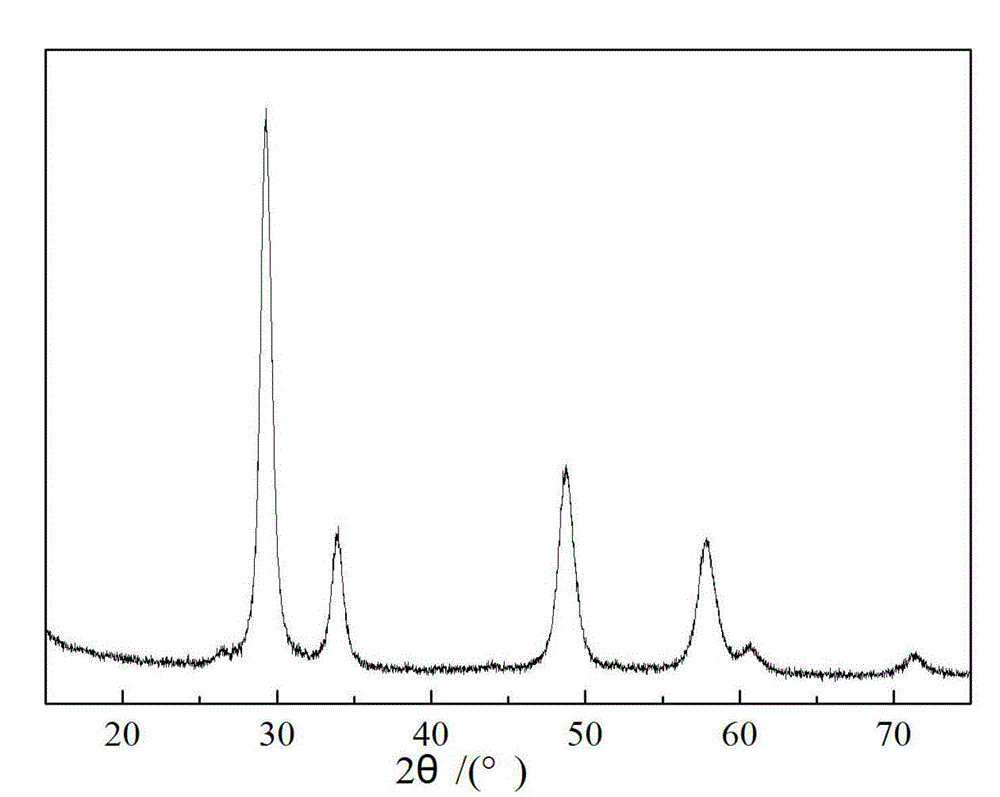

[0029] The carbonates of cerium, zirconium, lanthanum, yttrium, praseodymium, and neodymium were respectively dissolved in nitric acid until the solution was clear. After adjusting according to the distribution, add water to dilute to make the oxide mass concentration 300g / L, mix well to obtain a mixed salt solution, add Proper amount of hydrogen peroxide (the mass ratio of hydrogen peroxide to rare earth oxide is 0.3:1), stir evenly; add surfactant (oleic acid) into the ammonia water, stir evenly, drop the mixed salt solution into the ammonia water until the pH is 9-10 to precipitate Completely end, while maintaining the precipitation temperature at 40 ° C. After the precipitation, the precipitate needs to be kept at 50°C for 0.5 hours, then washed, burned at 800°C for 6 hours, pulverized, mixed, and aged at 1000°C for 10 hours to obtain the aged product. The specific surface area data are shown in Table 2.

[0030] Table 2 embodiment 4-6 specific surface area data table

[...

Embodiment 7-9

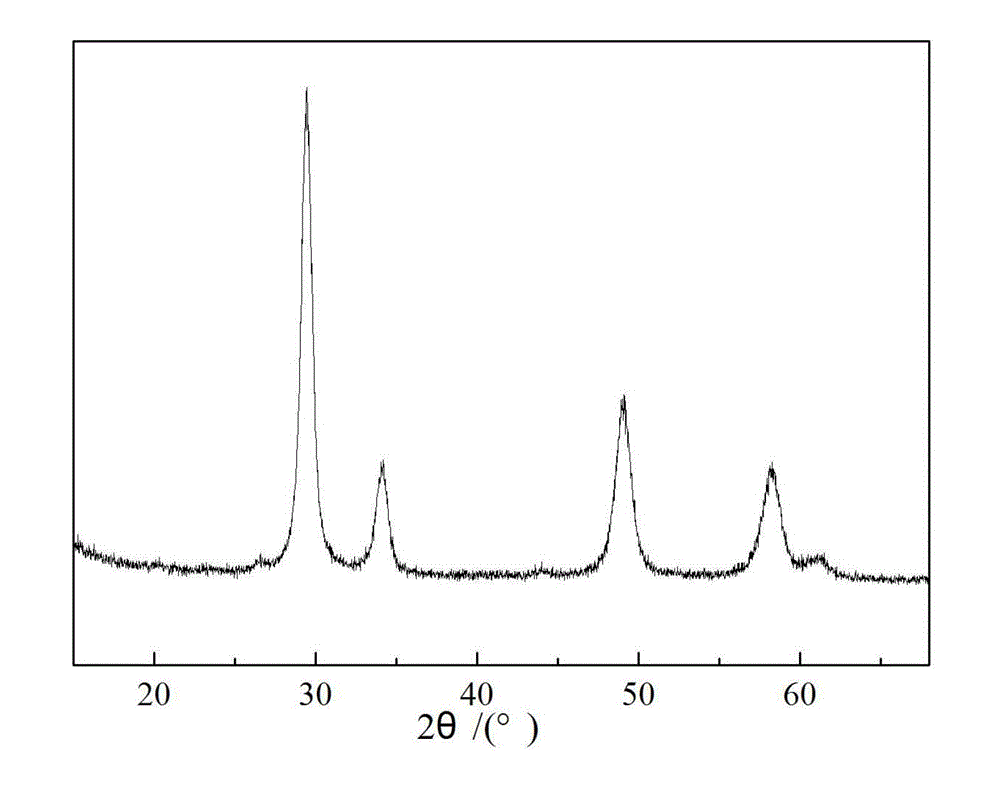

[0033] The carbonates of cerium, zirconium, lanthanum, yttrium, praseodymium, and neodymium were respectively dissolved in nitric acid until the solution was clear. After adjusting according to the distribution, add water to dilute to make the oxide mass concentration 20g / L, mix well to obtain a mixed salt solution, add Proper amount of hydrogen peroxide (the mass ratio of hydrogen peroxide to rare earth oxide is 3:1), stir evenly; add surfactant (oleic acid) into the ammonia water, stir evenly, drop the mixed salt solution into the ammonia water until the pH is 9-10 to precipitate Completely end, while maintaining the precipitation temperature at 25 ° C. After the precipitation, the precipitate needs to be kept at 30°C for 4 hours, then washed, burned at 500°C for 4 hours, pulverized, mixed, and aged at 1000°C for 10 hours to obtain the aged product. The specific surface area data are shown in Table 3.

[0034] Table 3 embodiment 7-9 specific surface area data table

[0035]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com