A kind of quartz tailings brick and preparation method thereof

A technology of quartz tailings and tailings bricks, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of unsatisfactory flexural and compressive strength, easy shrinkage, and easy water absorption of building bricks, etc. problems, achieve significant environmental protection value and economic benefits, and improve the effect of product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

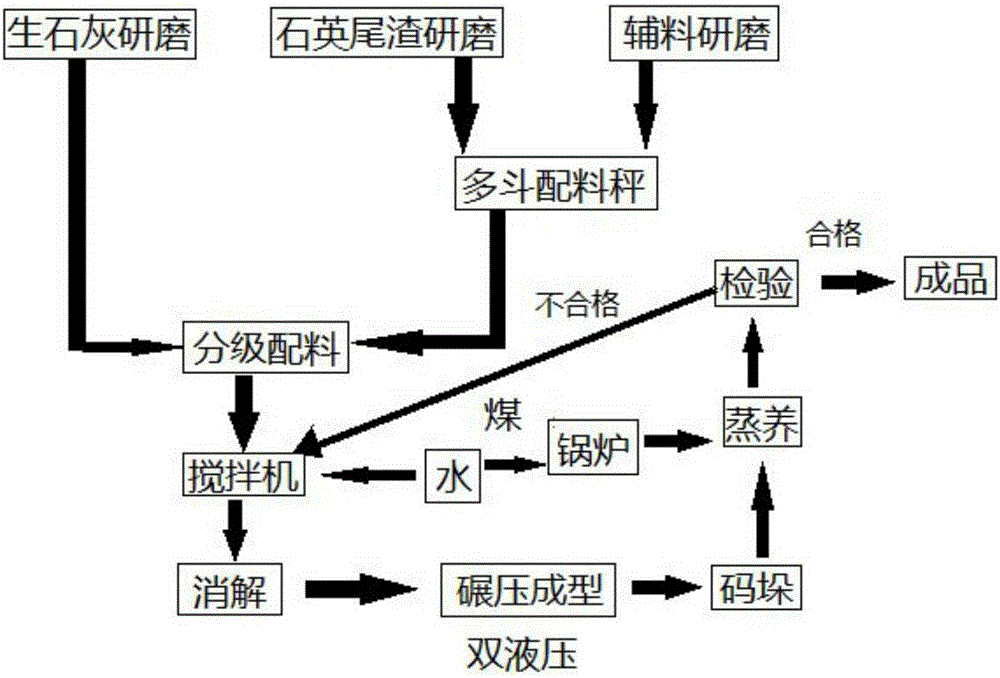

Method used

Image

Examples

Embodiment 1

[0041] A quartz tailing brick, the raw materials of which are: 65kg of quartz tailings, 7kg of quicklime, and 23kg of sand. The quartz tailings are extracted from the waste slag discharged from the fluorite mine in the chemical plant. Its main component is Content: SiO 2 95.01%, Fe 2 o 3 1.08%, Al 2 o 3 1.06%, CaO1.60%, MgO0.14%, K 2 O0.17%, Na 2 O0.15%, sulfide (as SO 3 Total) 0.15%, Cl — 0.01%, Loss0.93%;

[0042] Its preparation method is:

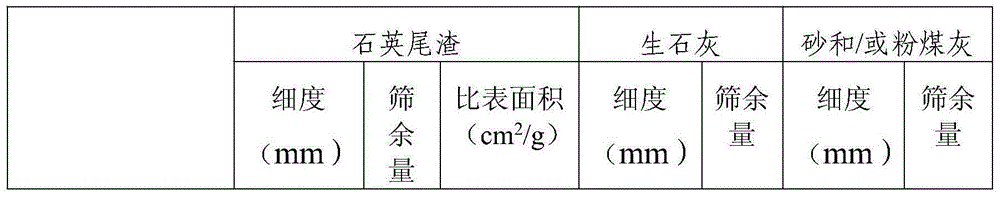

[0043] (1) Raw material grinding: the raw materials are respectively selected as: quartz tailings, quicklime, sand; specifically, the waste slag extracted from calcium fluoride from the fluorite mine is tested for component content, and its main raw material components are adjusted. Then pass through the grinding machine, first grind at 800r / min for 1h, then carry out high-speed grinding at 1300r / min for 30min at the rotating speed of the grinding machine, and after detecting and adjusting the main component content of the quar...

Embodiment 2

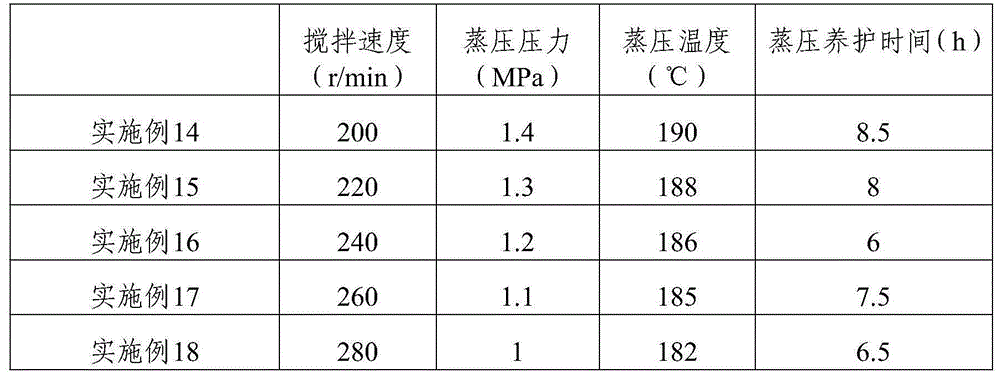

[0051] A kind of preparation method of quartz tailing brick, on the basis of embodiment 1, other steps are the same as embodiment, by selecting SiO 2 95.01kg, Fe 2 o 3 1.08kg, Al 2 o 3 1.06kg, CaO1.60kg, MgO0.14kg, K 2 O0.17kg, Na 2 O0.15kg, sulfide (as SO 3 Total) 0.15kg, Cl — 0.01kg, Loss0.93kg, after mixing, then detect its component content, and adjust its main raw material components, then pass through the grinder, first grind at 900r / min for 1.5h, and then grind at the speed of the grinder at 1350r Grinding at high speed for 30min at 1650r / min, and testing and adjusting the main component content of the quartz tailings, then passing through the grinder at 1650r / min, grinding for 15min, and then sieving with a square hole sieve, with a sieve residue of 15%. The fineness is 0.08mm, and it is sieved with a square hole sieve, and the specific surface area is 3000cm 2 / g; and digestion process 12h in the digestion step; in the rolling forming step, step 4) the digeste...

Embodiment 3

[0053] A kind of preparation method of quartz tailing brick, on the basis of embodiment 1, other steps are the same as embodiment, by selecting SiO 2 95.01g, Fe 2 o 3 1.08g, Al 2 o 3 1.06g, CaO1.60g, MgO0.14g, K 2 O0.17g, Na 2 O0.15g, sulfide (as SO 3 Count) 0.15g, Cl — 0.01g, Loss0.93g, after mixing, then detect its component content, and adjust its main raw material components, then pass through the grinder, first grind at 1000r / min for 2h, and then grind at the speed of the grinder at 1400r / min Grinding at high speed for 30 minutes at 1 min, and detecting and adjusting the main component content of the quartz tailings, then passing through the grinder at 1800r / min, grinding for 15 min, and then sieving with a square hole sieve, with a sieve residue of 20%. The density is 0.08mm, and it is sieved with a square hole sieve, and the specific surface area is 3300cm 2 / g; and digestion process 8h in the digestion step; in the rolling forming step, step 4) the digested bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com