Ferrocenyl polymer and porous material thereof, and preparation methods and application thereof

A ferrocene-based, polymer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

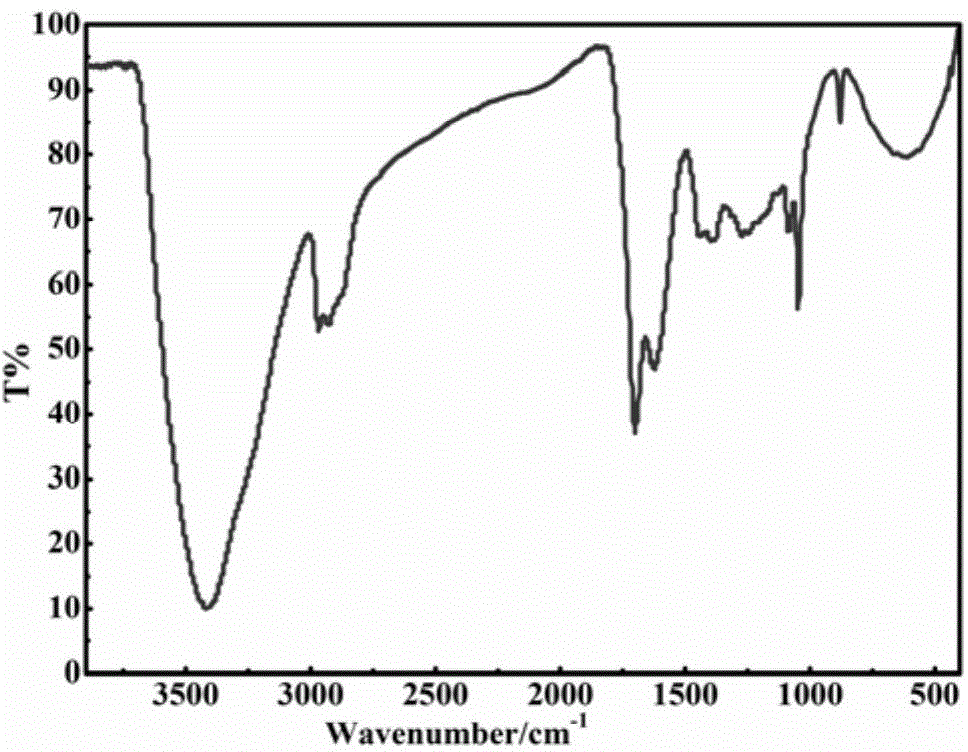

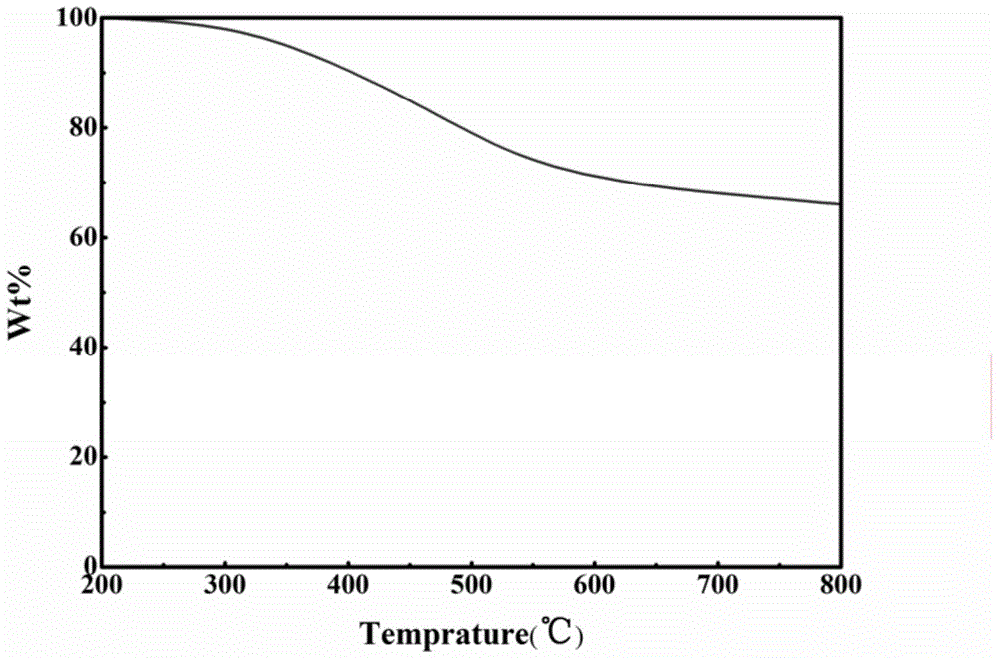

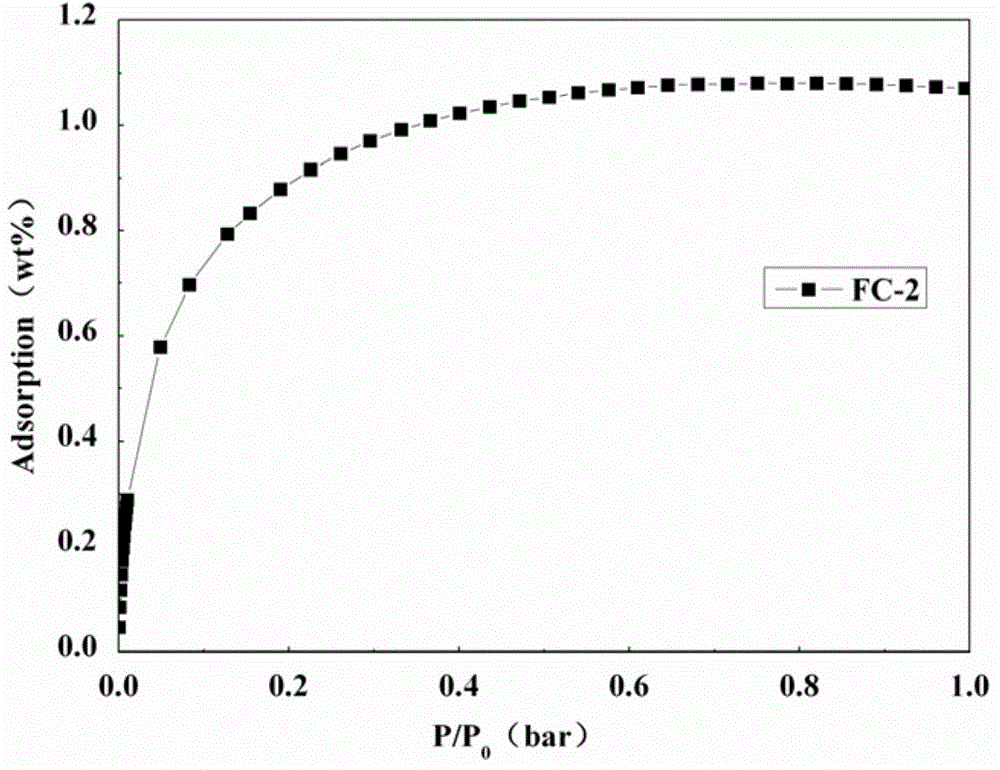

[0038] In a 250mL three-neck flask equipped with mechanical stirring, a reflux condenser and a constant pressure dropping funnel, add 6 parts of triazine chloride, 20 parts of methanesulfonic acid, and 90 mL of o-dichlorobenzene in sequence. After reacting for 2 hours, 40 mL of o-dichlorobenzene solution dissolved in 9 parts of ferrocene was added dropwise, and the temperature was raised to 180° C. and refluxed for 12 hours. After the reaction solution is cooled, the resulting precipitate is collected by filtration, washed with alcohol, acid washed, extracted with THF, and dried to obtain the product. The sample is heated to 180-200° C. for 8 hours under vacuum condition (10 kPa) to activate the ferrocene-based polymer porous material. Measure TGA and BET respectively, the specific surface area is 875m2 / g, the average pore diameter is 3.15nm, the 5% thermal weight loss temperature under nitrogen is 410°C, the carbon dioxide adsorption capacity is 14.5wt% (298K, 1bar), the hyd...

Embodiment 2

[0040] In a 250mL three-neck flask equipped with mechanical stirring, reflux condenser and constant pressure dropping funnel, add 5 parts of trimesoyl chloride, 20 parts of aluminum chloride, and 90 mL of 1,2-dichloroethane in sequence, under nitrogen protection conditions React at 30°C for 4 hours, then add dropwise 40 mL of 1,2-dichloroethane solution dissolved in 9 parts of ferrocene, raise the temperature to 50°C and reflux for 6 hours, then raise the temperature to 120°C and reflux for 12 hours. After the reaction solution was cooled, the resulting precipitate was collected by filtration, washed with ethanol and dilute hydrochloric acid, extracted with THF overnight, and dried to obtain a ferrocene-based polymer product. The sample is heated to 180-200° C. for 20 h under vacuum condition (10 kPa) to activate the ferrocene-based polymer porous material. Measure TGA and BET respectively, the specific surface area is 1050m 2 / g, the average pore size is 2.45nm, the temperat...

Embodiment 3

[0042] In a 250mL three-neck flask with mechanical stirring, reflux condenser and constant pressure dropping funnel, add 2 parts of 1,3,5-trichloroformylphenyladamantane, 6 parts of pyridine trifluoromethanesulfonate, 60mL of 1,2-dichloroethane was reacted at 70°C for 3 hours under nitrogen protection, then 30ml of 1,2-dichloroethane solution containing 3 parts of ferrocene was added dropwise, and the temperature was raised to 150°C and refluxed for 24h After cooling the reaction solution, the resulting precipitate was collected by filtration, washed with ethanol and dilute hydrochloric acid, extracted with THF overnight, and dried to obtain a ferrocene-based polymer product. The sample is heated to 180-200° C. for 10 h under vacuum condition (10 kPa) to activate the ferrocene-based polymer porous material. The samples were tested for TGA and BET respectively, and the specific surface area was 712m 2 / g, the average pore size is 4.11nm, the temperature of 5% thermal weight lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com