Polymer waterborne paint with corresponding features to ultraviolet light

A technology of water-based coatings and polymers, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of single-function polymer water-based coatings, and achieve the effects of easy observation, easy coating, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

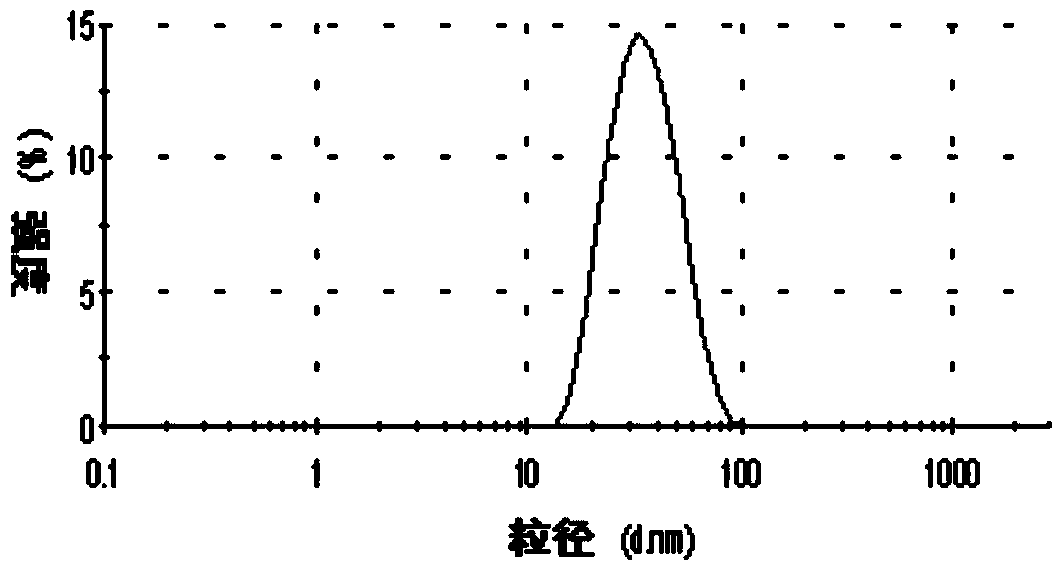

[0043] The aqueous dispersion of nanopolymer particles containing spiropyran photochromic molecular groups described in this example is synthesized by a miniemulsion polymerization process, including the following steps:

[0044] 1) Prepare water phase: mix emulsifier, pH buffer solution and water, described emulsifier is sodium dodecylsulfonate, described pH buffer agent is sodium bicarbonate; Wherein sodium lauryl sulfate content 20mmol / L, sodium bicarbonate content 10mmol / L; the rest is water;

[0045] 2) Prepare oil phase: mix monomer, crosslinking agent and co-stabilizer, said monomer is selected from 0.1 part of N-hydroxyethylspiropyranyl methacrylate and 2 parts of methyl methacrylate, so The crosslinking agent is selected from 0.1 part of 1,4-butanediol diacrylate, and the co-stabilizer is 0.05 part of polystyrene with a weight average molecular weight of 5000;

[0046] 3) Mixing and emulsification: the water phase and the oil phase are mixed and emulsified and homog...

Embodiment 2

[0051]Only change the commercially available Dulux white polyacrylate interior wall latex paint into Dulux white polyacrylate exterior wall white latex paint in step 2) of embodiment 1, and the rest are identical to embodiment 1.

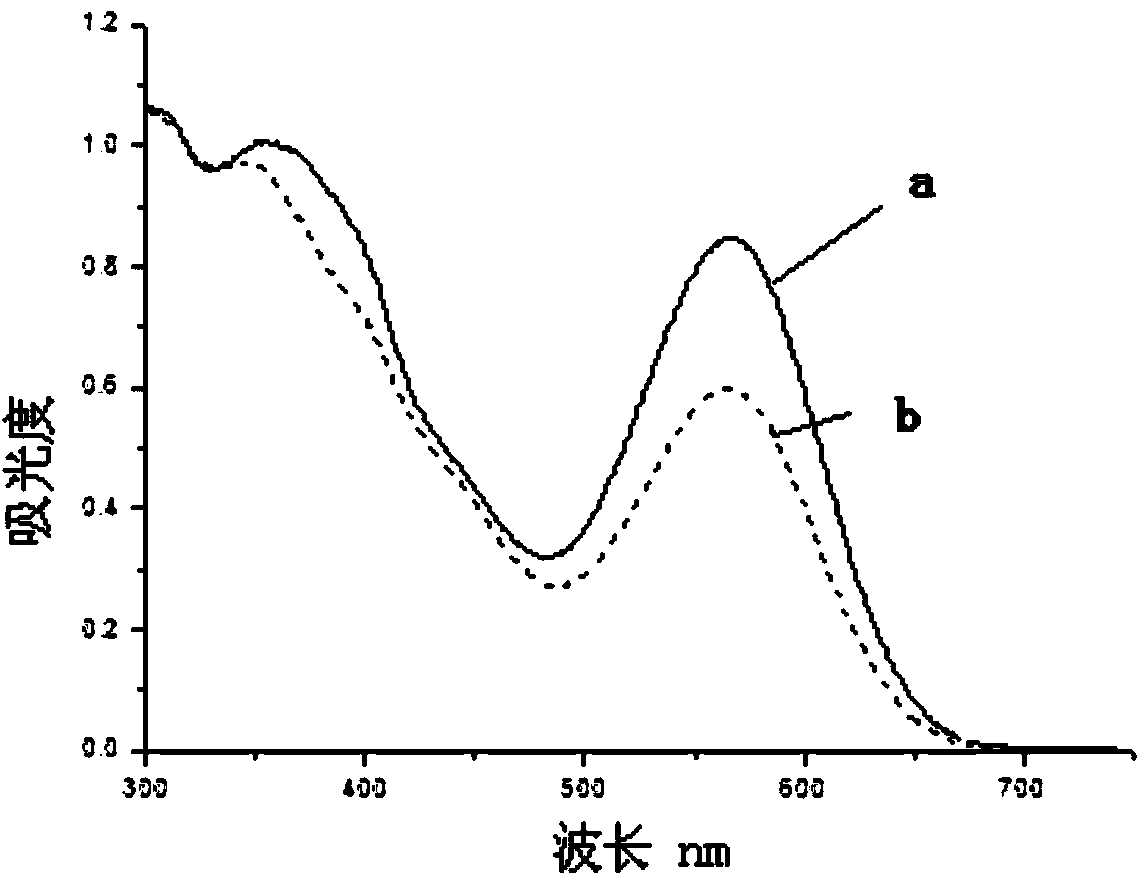

[0052] Apply the polymer water-based paint prepared above to pure wood pulp thick paper by heat-sealing, and form a film after drying, put it in a transparent plastic bag and hang it at the place where the ultraviolet disinfection lamp is exposed. After a few minutes, the color changes from colorless or Very light purple to dark blue-purple. The color returns to its original light state after hours of exposure to white light.

Embodiment 3

[0054] Only change the cross-linking agent in step 1) of Example 1 into 0.2 part of divinylbenzene, and the rest are identical to Example 1.

[0055] Apply the polymer water-based paint prepared above to pure wood pulp thick paper by heat-sealing, and form a film after drying, put it in a transparent plastic bag and hang it at the place where the ultraviolet disinfection lamp is exposed. After a few minutes, the color changes from colorless or Very light purple to dark blue-purple. The color returns to its original light state after hours of exposure to white light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com