A method for producing phenylalanine by microbial fermentation

A fermentation method, phenylalanine technology, applied in the field of bioengineering, can solve problems such as slow cell growth, achieve the effects of improving economic benefits, reducing the amount of feeding, and reducing the amount of ammonium sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 This example illustrates the method of producing L-phenylalanine using Escherichia coli BL21, which is preserved by our laboratory. (Escherichia coli BL21 was purchased from Beijing Quanshijin Biotechnology Co., Ltd.)

[0024] Specifically include the following steps:

[0025] (1) Activation of strains: During slant culture, the strains are cultured in a constant temperature incubator after streaking on the slant medium, at a temperature of 30-40°C, and the activation culture time is 1-2d, which is used for seed medium inoculation and strain preservation;

[0026] (2) Seed cultivation: add 50mL of seed culture medium to a 500mL Erlenmeyer flask, sterilize with high-pressure steam at 121°C for 20 minutes, and insert strains on the slant medium after cooling.

[0027] (3) Fermentation culture: the volume of fermentation medium in a 1L fermenter is 0.5-0.8L, the inoculum size is 5%-10% (v / v), the temperature is 30-40°C, the stirring speed is 200-500rpm, and the...

Embodiment 2

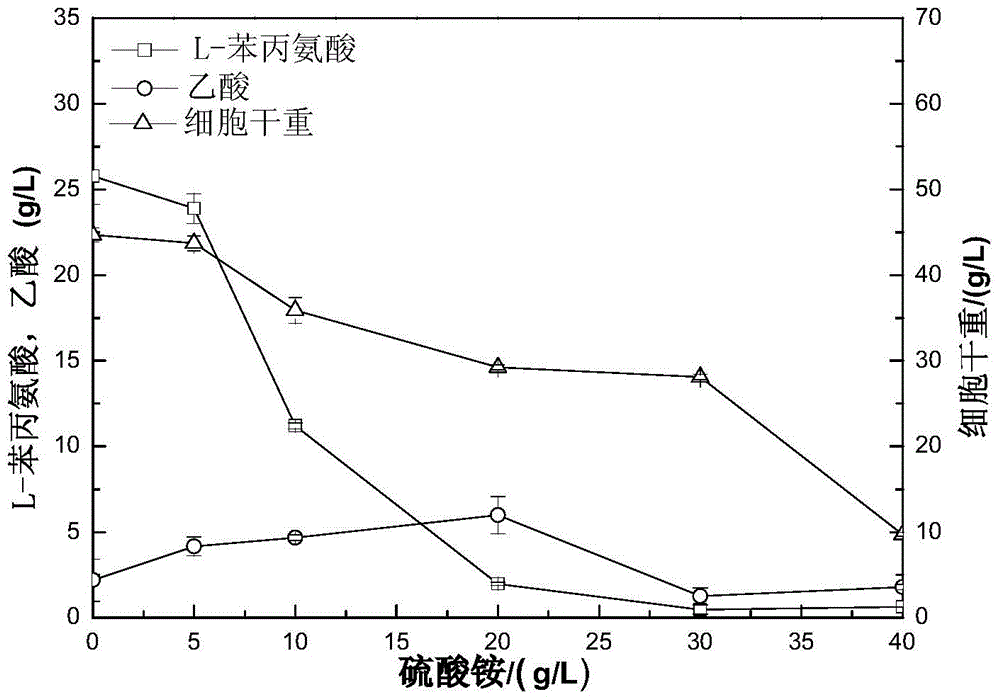

[0031] Example 2 This example illustrates the optimization method for the preparation of L-phenylalanine by Escherichia coli BL21 (pET / P-aspC), mainly involving the optimization of ammonium sulfate concentration

[0032] In this embodiment, the bacterial strain used is Escherichia coli BL21 (pET / P-aspC), and the concentration of ammonium sulfate (g / L) in the fermentation medium is 0, 5, 10, 20, 30 respectively. Other cultivation and fermentation methods and implementation Example 1 is the same.

[0033] In this example, different concentrations of ammonium sulfate were used to ferment and prepare L-phenylalanine, and the results were as follows figure 1 shown. Ammonium sulfate contains nitrogen required for bacterial growth and amino acid production, but an excess supply of ammonium ions can lead to competitive inhibition problems. Studies have shown that ammonium concentrations exceeding 3-5g / L tend to cause inhibition. Such as figure 1The ammonium sulfate of initial 10g / ...

Embodiment 3

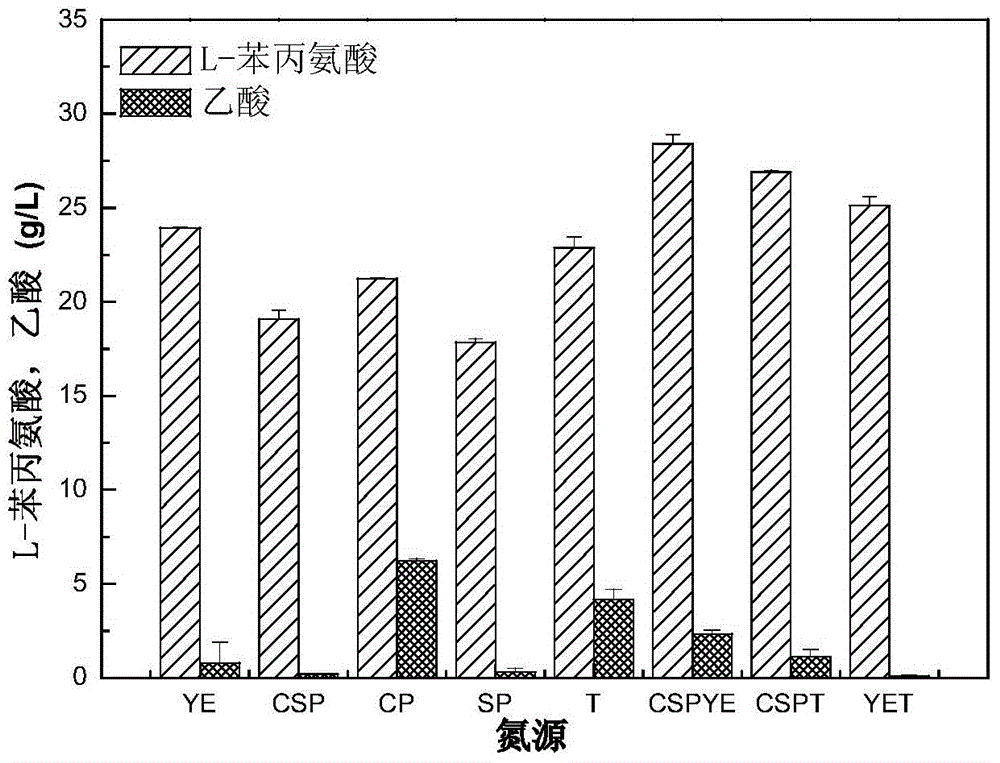

[0034] Example 3 This example illustrates the optimization method for the preparation of L-phenylalanine by Escherichia coli BL21 (pET / P-aspC), which mainly involves the optimization of the types of organic nitrogen sources

[0035] In this example, the strain used is Escherichia coli BL21 (pET / P-aspC), the type of organic nitrogen source in the fermentation medium is changed, and other cultivation and fermentation methods are the same as in Example 1.

[0036] The above-mentioned organic nitrogen sources are respectively a single organic nitrogen source and a compound organic nitrogen source, and the total nitrogen amount of the added organic nitrogen source is equivalent; in the compound organic nitrogen source, the two single organic nitrogen sources are calculated according to their nitrogen content 1:1 added; the type and concentration of a single organic nitrogen source are yeast powder 10g / L, corn steep liquor dry powder 11.5g / L, cottonseed cake powder 10g / L, bean cake e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com